Two-phase flow liquid storage flow stabilizer

A two-phase flow liquid storage and flow stabilizer technology, which is used in refrigeration and liquefaction, refrigeration components, refrigerators, etc., can solve the problems of simple structure and single performance, and achieve the effect of simple structure, single performance and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

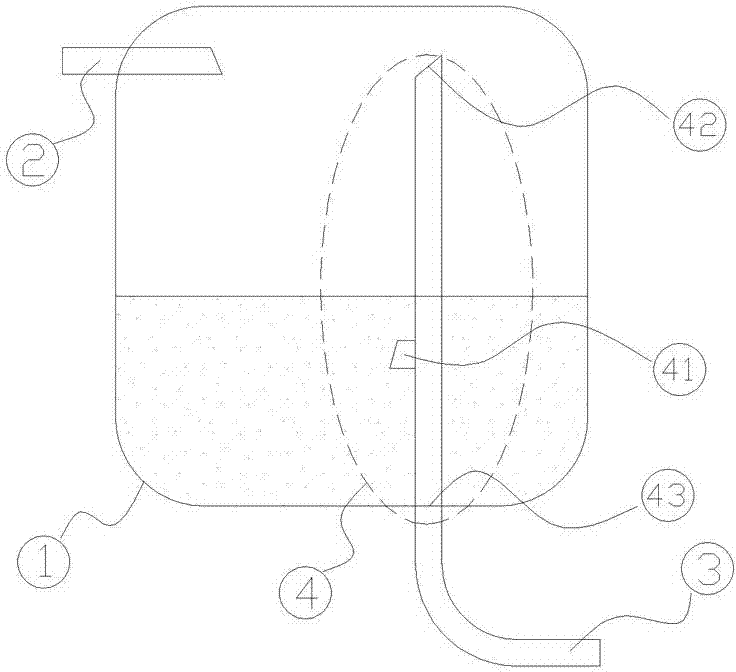

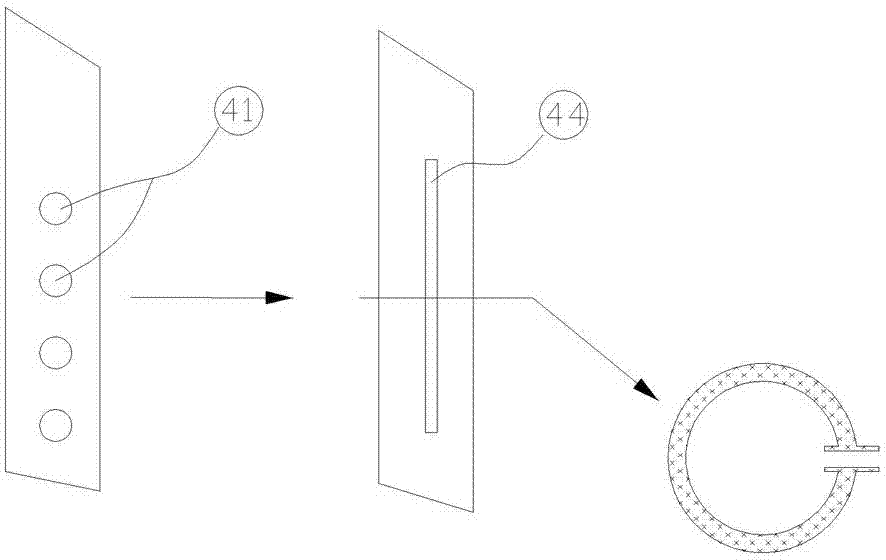

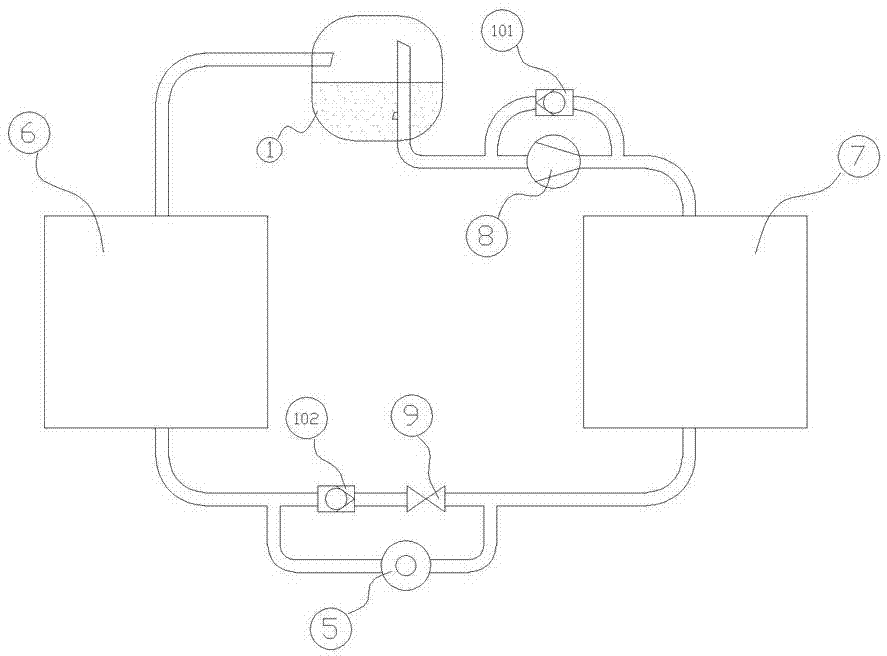

[0019] Such as image 3 The schematic diagram for the use of the two-phase flow liquid storage and stabilizer is shown, including the circulation pump (5), evaporator (6), condenser (7), two-phase flow liquid storage and current stabilizer, compressor (8), Throttle valve (9), one-way valve (101)~(102) and the connecting pipes between them; when the heat pump cycle mode is working, the compressor (8) will flow from the two-phase flow liquid storage stabilizer according to a certain ratio A large amount of low-pressure gaseous refrigerant is extracted through a port (42) of the two-phase flow distribution pipe (4) and a small amount of low-pressure liquid refrigerant is extracted through the return hole (41), and compressed into high-temperature and high-pressure gas-liquid saturated two-phase steam, gas-liquid The saturated two-phase steam is sent into the condenser (7), and the condenser (7) is in contact with the low-temperature heat source, and the gaseous working medium is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com