Dual-interface card packaging method

A packaging method and dual-interface card technology, applied to record carriers, instruments, and electrical components used in machines, can solve problems such as affecting quality and restricting efficiency, avoiding oxidation or welding at solder joints, simplifying process links, The effect of reducing process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

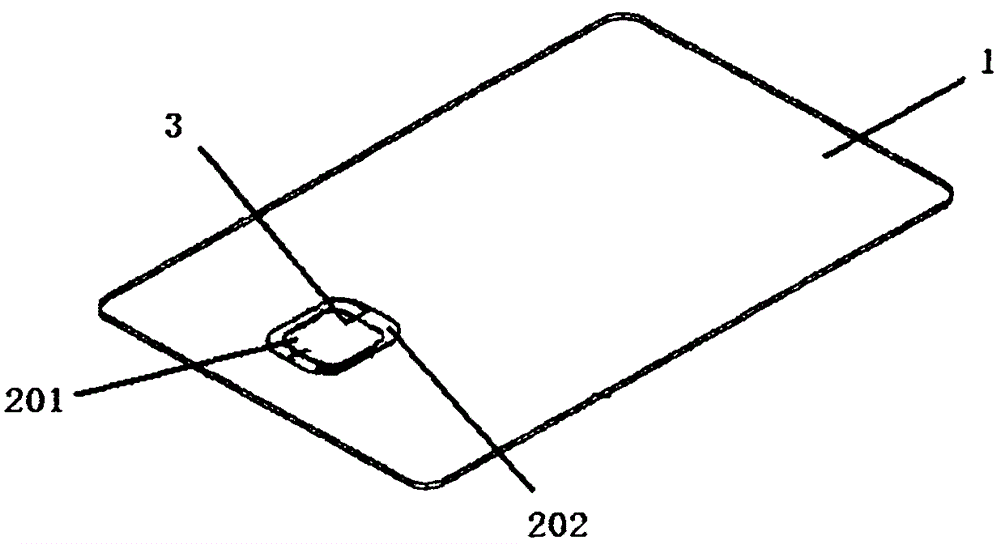

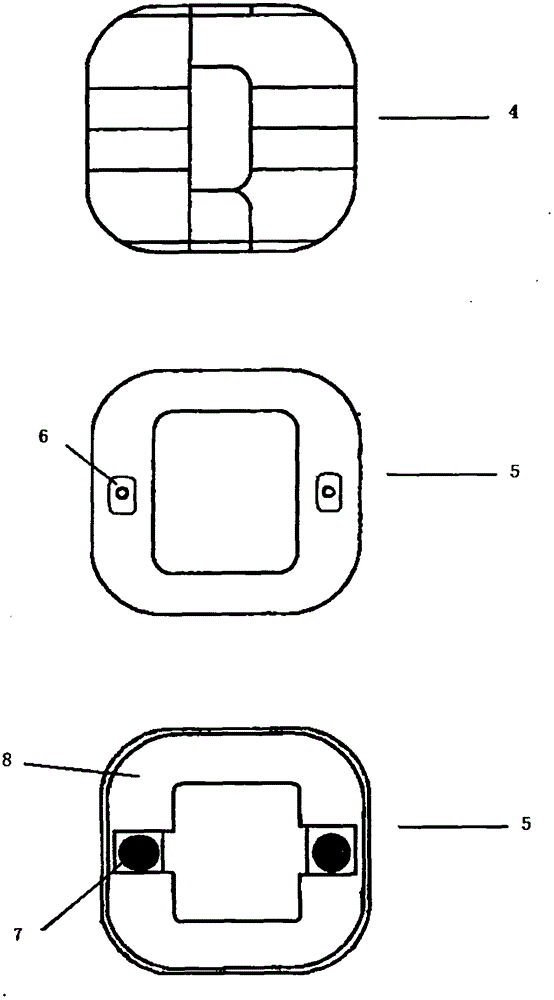

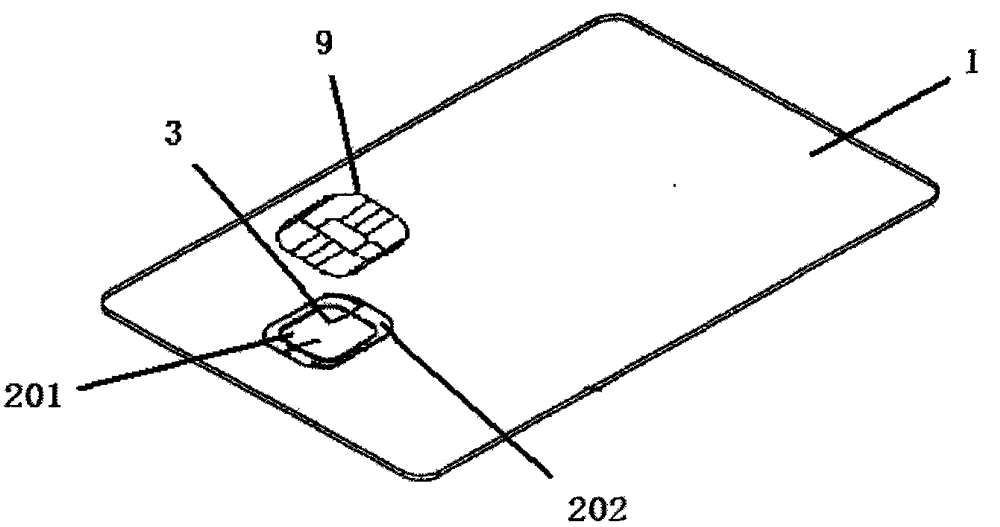

[0016] Figure 1 to Figure 5 Shown is a preferred embodiment of the invention. figure 1 Shown is a card body 1 with a slot already milled. There is already an antenna in the card body 1. The slot is divided into an inner slot 201 and an outer slot 202. The area of the outer slot is larger than the area of the inner slot. You can mill the slot first The outer groove 202 is milled after the inner groove 201, or the outer groove 202 can be milled first, and then the inner groove 201 is milled. In this embodiment, the inner groove 201 is milled first, and then the outer groove 202 is milled. The groove that mills out is used for placing chip 9, and the size and will match with chip 9. During the groove milling process, the antenna joint 3 in the card body 1 should be exposed by milling, and the length of the exposed antenna joint 3 should be greater than 0.5 mm and less than 3.5 mm. If the antenna connector 3 is too short, it may not be in contact with the solder paste 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com