Multi-spectral spectroscopic photography-based visual monitoring system

A monitoring system and multi-spectral technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of inability to obtain clear and stable front bevel images, easy introduction of errors, weakened light intensity, etc., to achieve image registration and The effect of subsequent image fusion is convenient, accuracy and stability are guaranteed, and interference is avoided

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

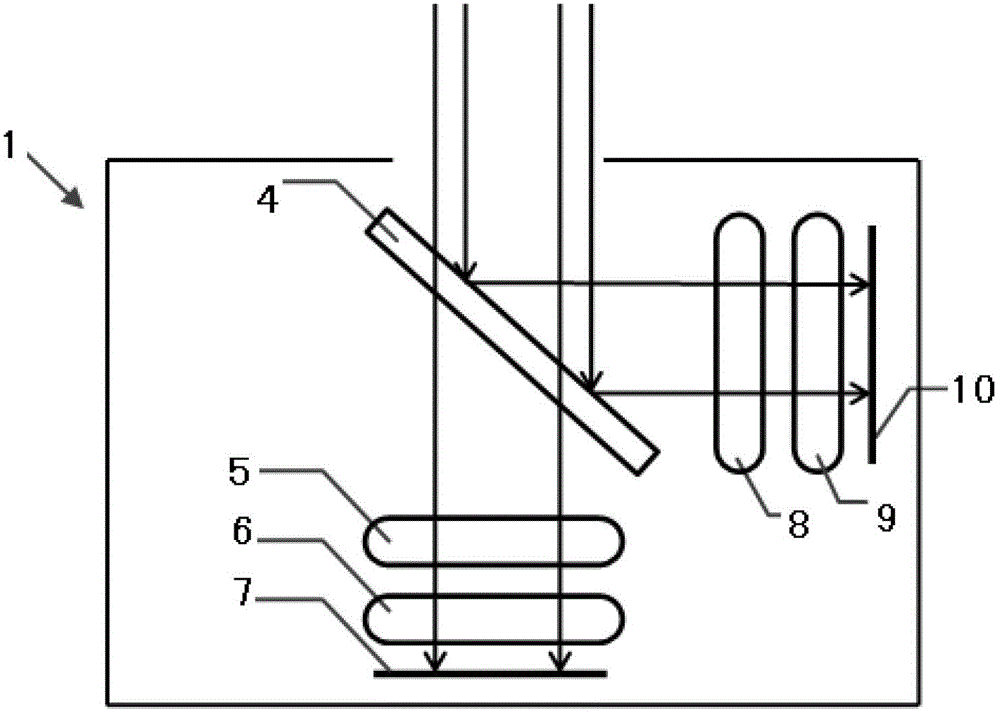

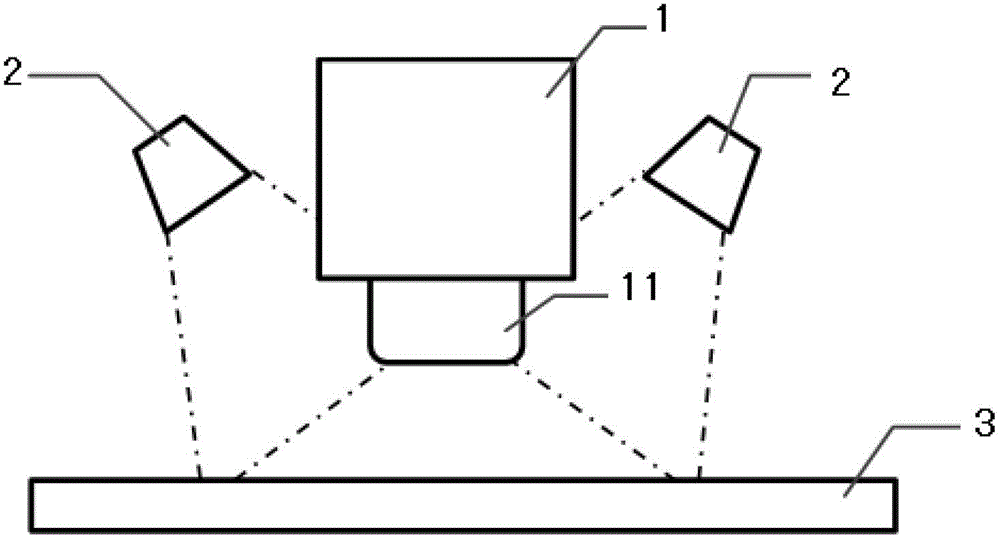

[0025] Such as Figure 4 As shown, the present embodiment takes the front groove as the welding workpiece 3 for description, the auxiliary light source 2 includes a ring-shaped LED surface light source 21 with a wavelength of 980nm and a laser line structured light source 22 with a wavelength of 660nm, and the lens 11 of the camera 1 passes directly below The peripheral bracket fixes the annular LED surface light source 21, and one side of the camera 1 fixes the laser line structured light source 22 through the peripheral bracket. This can be adjusted according to the actual situation), the center wavelength of the first narrow-band filter 5 is 980nm, and only light with a wavelength within the range of 980nm±20nm can pass through the first narrow-band filter 5, and the second narrow-band filter The central wavelength of sheet 8 is 653nm, wherein only the light energy within the range of 653nm ± 18nm can pass through the second narrow-band filter 8, the light transmittance of ...

Embodiment 2

[0028] Such as Figure 5 The present embodiment shown is described with the front groove as the welding workpiece 3, and one side of the camera 1 is fixed with an infrared laser illumination source 2 with a wavelength of 1060 nm through an external bracket, and the infrared laser illumination source 2 is used as an auxiliary light source. The normal line is 45° to the optical axis direction of the lens 11 of the camera 1 (not limited to this, it can be adjusted according to the actual situation), the central wavelength of the first narrow-band filter 5 is 1060nm, and only the wavelength is within the range of 1060nm±20nm The light can pass through the first narrow-band filter 5, the center wavelength of the second narrow-band filter 8 is 653nm, wherein only the light with a wavelength in the range of 653nm ± 18nm can pass through the second narrow-band filter 8, the first subtraction The light transmittance of the light sheet 6 is 1%, the light transmittance of the second ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com