Self-adoption multi-oil chamber constant static pressure system with big flow variation range

A range and static pressure technology, applied in the field of multi-chamber constant flow static pressure system, to achieve the effect of low oil pollution degree and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

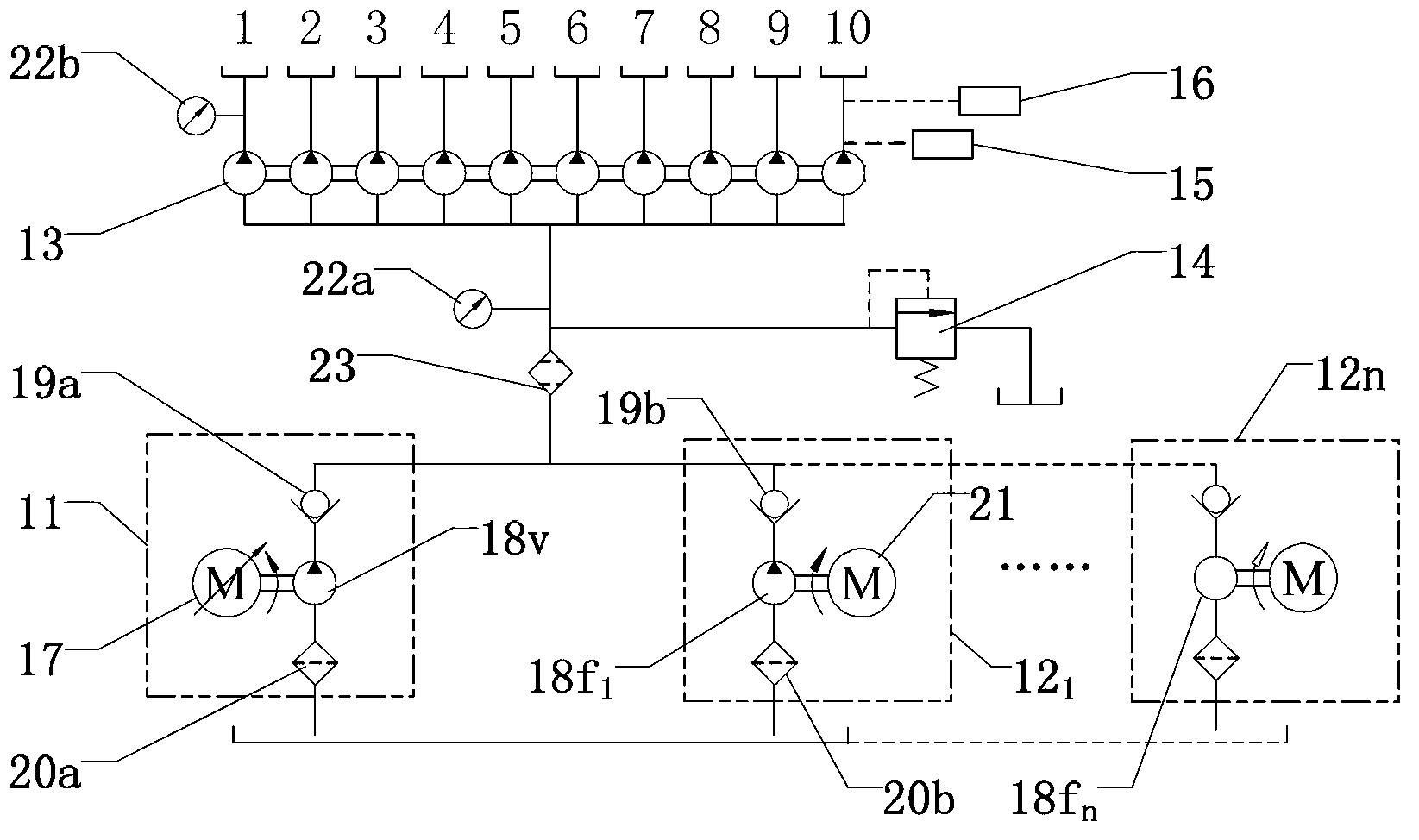

[0040] The self-adaptive, multi-oil cavity constant-flow static pressure system and working principle of the present invention with a large flow range will be further described in conjunction with the accompanying drawings.

[0041] figure 1 Provided in the present invention is the hydraulic principle diagram of the multi-oil cavity heavy-duty vertical lathe workbench constant flow static pressure guide rail oil supply system. There are 10 static pressure oil chambers shown in the figure, namely n e =10, its labels are respectively 1, 2, ..., 10, so other drawing marks of the present invention start to mark from No. 11.

[0042] It includes a variable fuel supply module 11, one or more quantitative fuel supply modules 12 1 ,...,12 n , Multi-point gear oil separator 13, relief valve 14, pressure sensor 15, temperature sensor 16 and other components. Variable oil supply module 11 is composed of variable frequency motor 17, quantitative pump 18v, check valve 19a and oil filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com