Method for generating hydrogen by hydrolyzing lithium borohydride and reacting device used for method

A technology of lithium borohydride and hydrogen, which is applied in the field of hydrogen sources for micro-fuel cells, can solve problems such as slow reactions, achieve the effects of reducing the rate of hydrogen desorption, stable and controllable hydrogen desorption reactions, and promoting the process of practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

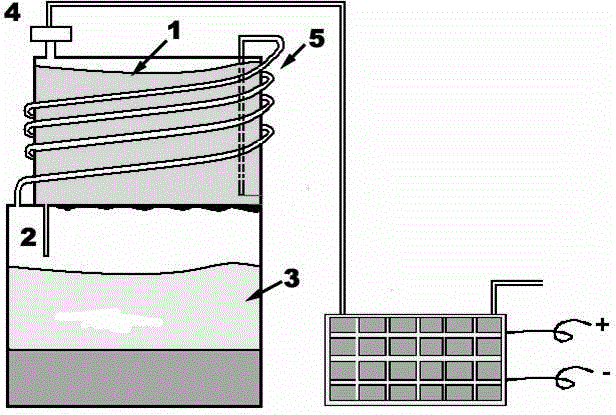

[0025] The reaction device used in this example is as figure 1 As shown, it includes a liquid water storage chamber 1, a water inlet capillary 2, a hydrolysis reaction chamber 3, a gas feedback pipeline 5 and an interface 4 connected to a fuel cell, and one end of the water inlet capillary 2 communicates with the liquid water storage chamber 1 , the other end is placed in the hydrolysis reaction chamber 3, one end of the gas feedback pipeline 5 is inserted into the liquid water in the liquid water storage chamber 1, and the other end communicates with the hydrolysis reaction chamber 3. The diameter of the water inlet capillary 2 is 5-30 μm.

[0026] 1 g LiBH 4 Mix with 23 mL of diethyl ether solvent, that is, place it in the hydrolysis reaction chamber 3 of the reaction device according to the ratio of the saturated solution, and mechanically stir at 100 rpm until a uniform solution is formed, then seal the reaction device, communicate with the fuel cell, and pass through the...

Embodiment 2

[0028] The anyway device used in this embodiment is the same as in Embodiment 1.

[0029] 1 g LiBH 4 Mix with 23 mL of diethyl ether solvent, that is, first place it in the hydrolysis reaction chamber 3 of the reaction device according to the ratio of the saturated solution, and mechanically stir at 100 rpm until a uniform solution is formed, then add 1 g of LiBH 4Solid powder, continue to stir for 2 hours, then seal the reaction device, communicate with the fuel cell, and inject excess liquid water into the liquid water storage chamber 1 through a micro pump. Liquid water drops into the hydrolysis reaction chamber 3 to react with the supernatant (saturated solution) of the supersaturated solution, and the generated reaction product is deposited at the bottom of the reactor, and the consumed LiBH 4 will be removed by the LiBH at the bottom 4 Dissolved solids are continuously replenished. The rate of hydrogen produced by the system is 72mLmin -1 g -1 , the final LiBH 4 Th...

Embodiment 3

[0031] The anyway device used in this embodiment is the same as in Embodiment 1.

[0032] 1 g LiBH 4 Mix with 23 mL of diethyl ether solvent, that is, first place it in the hydrolysis reaction chamber 3 of the reaction device according to the ratio of the saturated solution, and mechanically stir at 100 rpm until a uniform solution is formed, then add 3 grams of LiBH 4 Solid powder, continue to stir for 2 hours, then seal the reaction device, communicate with the fuel cell, and inject excess liquid water into the liquid water storage chamber 1 through a micro pump. Liquid water drops into the hydrolysis reaction chamber 3 to react with the supernatant (saturated solution) of the supersaturated solution, and the generated reaction product is deposited at the bottom of the reactor, and the consumed LiBH 4 will be removed by the LiBH at the bottom 4 Dissolved solids are continuously replenished. The rate of hydrogen produced by the system is 160mLmin -1 g -1 , the final LiBH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com