Preparation method of three-dimensional ordered macroporous titanium dioxide material

A titanium dioxide, three-dimensional ordered technology, applied in the field of preparation of three-dimensional ordered macroporous materials, can solve the problems of low preparation efficiency of three-dimensional ordered macroporous materials, material thickness and mechanical strength, etc., to overcome the difficult control of conditions and speed up the assembly speed , the effect of efficient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: in the polystyrene microsphere (particle diameter 340nm) emulsion of 30mL monodisperse (dispersion coefficient 0.0030), add 3mL titania sol (particle diameter 12nm), ultrasonic vibration mixes, obtains binary component mixed solution; The binary component mixture obtained above was placed in a glass vessel, and evaporated at a constant temperature for 5 hours at a temperature of 40°C to obtain a binary co-deposited solid; after roasting the above binary co-deposited solid at 480°C for 3 hours, cool slowly Finally, a three-dimensional ordered macroporous titanium dioxide material is obtained.

Embodiment 2

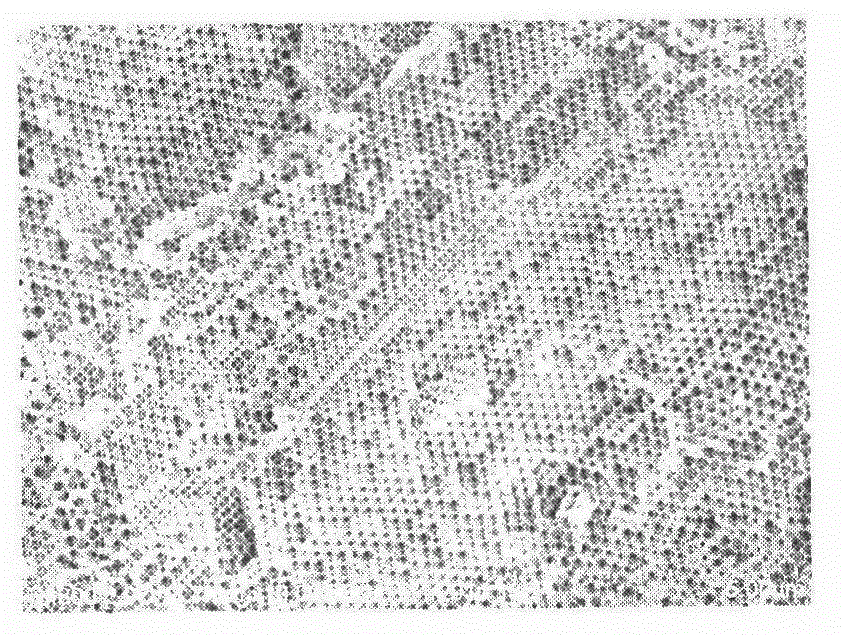

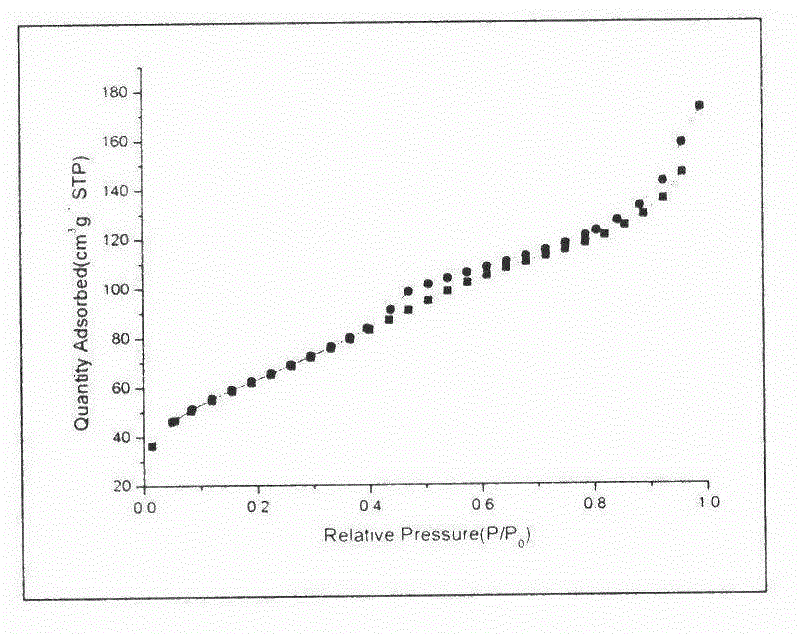

[0020] Embodiment 2: in the polystyrene microsphere (particle diameter 250nm) emulsion of 30mL monodisperse (dispersion coefficient 0.0030), add 3mL titania sol (particle diameter 16nm), ultrasonic vibration mixes, obtains binary component mixed solution; The binary component mixture obtained above was placed in a glass vessel, and evaporated at a constant temperature for 5 hours at a temperature of 60°C to obtain a binary co-deposition solid; after roasting the above binary co-deposition solid at 500 °C for 4 hours, slowly After cooling, a titanium dioxide / heteropolyacid composite photocatalyst is obtained. figure 1 It is a scanning electron micrograph of the three-dimensional ordered macroporous titanium dioxide material. figure 2 It is the pore structure analysis of three-dimensional ordered macroporous titania materials.

Embodiment 3

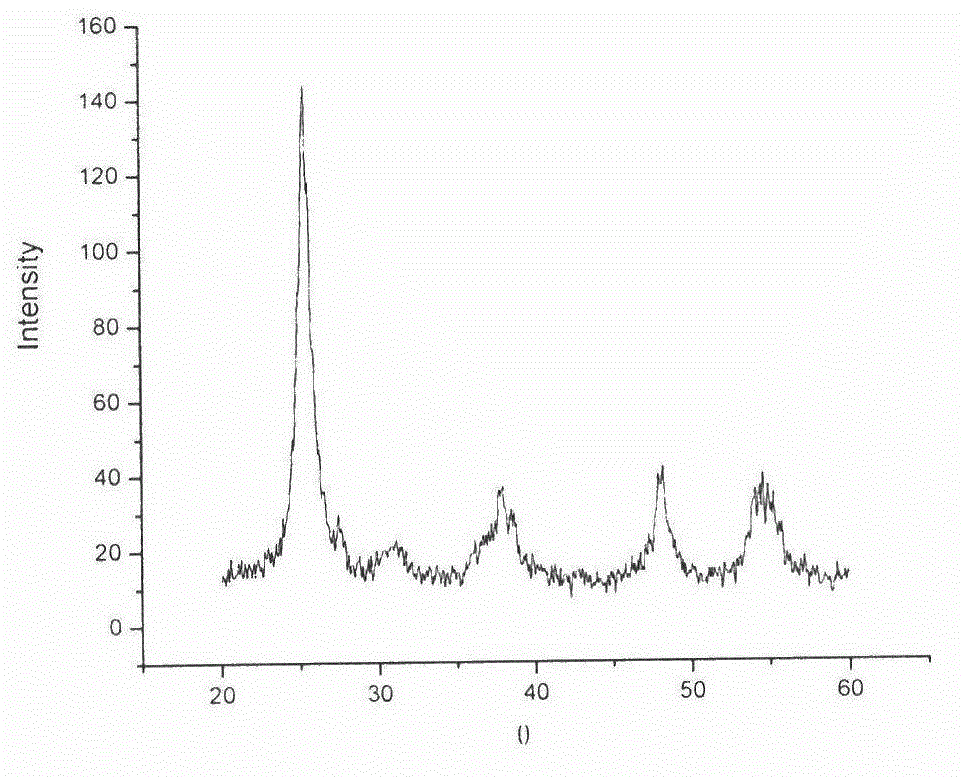

[0021] Example 3: In 30 mL of monodisperse (dispersion coefficient 0.0030) polystyrene microsphere (particle diameter: 380 nm) emulsion, add 3 mL of titanium dioxide sol (particle diameter: 20 nm) and mix with ultrasonic vibration to obtain binary component mixture; Put the binary component mixture obtained above in a glass vessel, and evaporate at a constant temperature for 6 hours at a temperature of 60°C to obtain a binary codeposited solid; after roasting the above binary codeposited solid at 520°C for 3 hours, After slow cooling, a three-dimensional ordered macroporous titania material is obtained. image 3 is the X-ray diagram of the three-dimensional ordered macroporous titanium dioxide material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com