Ore-powder-doped high-performance shotcrete applicable to underground watertight oil cellars and preparation method thereof

A technology of sprayed concrete and groundwater, which is applied in the field of high-performance shotcrete mixed with mineral powder and its preparation, which can solve the problems of stagnation, incomplete adaptation, and inapplicability to underground water-sealed oil depots, etc., and achieves extended service life, low cost, and high bond strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

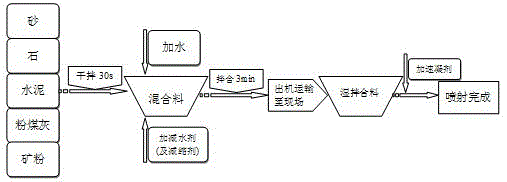

Method used

Image

Examples

Embodiment

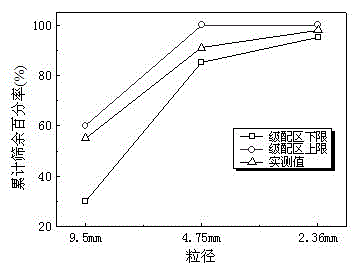

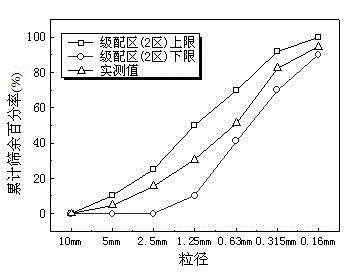

[0034]The main raw materials are cement, mineral admixture, aggregate, water reducer, shrinkage reducer and accelerator. The cement is P.O.42.5 ordinary Portland cement. Mineral admixtures are S95 grade high-quality mineral powder and I grade fly ash. The S95 grade high-quality mineral powder adopted in this embodiment has a specific surface area of 450m 2 / kg, the 7-day activity index was 85%, the 28-day activity index was 108%, and the fluidity ratio was 103%; the water demand ratio of the Class I fly ash used in this example was 98%. The water reducing agent is a polycarboxylic acid type high-efficiency water reducing agent, and the theoretical water reducing rate is 25%; the accelerator is an alkali-free liquid accelerator, and the solid content is 38%. The dosage of the accelerator in this embodiment is 6% of the mass of the cementitious material, which is cement and mineral admixtures.

[0035] The shrinkage reducing agent is mainly composed of 20% by weight polyacry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com