Finger extrusion-frangible soft capsule and its preparation method and use

A technology of soft capsules and fingers, applied in the fields of tobacco preparation, application, food science, etc., can solve the problems of complex preparation process and strict curing conditions, and achieve the effect of simple and easy process and changing flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method for finger-extruded friable soft capsules, comprising the steps of:

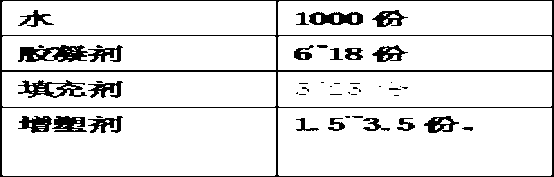

[0031] (1) Weigh 1000g of water, 10g of carrageenan, 5g of cyclodextrin, and 2g of sorbitol, and add water, plasticizer, gelling agent and filler into the plastic tank in sequence at 70°C, and stir until the materials are fully dissolved , heat preservation and degassing.

[0032] (2) The seamless capsules were prepared by co-extrusion method, and the extrusion temperature was 70°C.

[0033] (3) Soak the extruded substantially spherical seamless capsule in methyl silicone oil for 1.5 hours.

[0034] (4) Air-dry the soft capsule produced in step (3) for 24 hours in an environment with a temperature of 20°C and a humidity of 40%, and fully dry.

[0035] (5) Wipe the dried soft capsules with oil-absorbing paper to remove the coagulation liquid remaining on the surface of the capsules.

[0036] The diameter of the soft capsule prepared above is 3.5±0.1mm.

[0037] Use the DPYD-A d...

Embodiment 2

[0041] A preparation method for finger-extruded friable soft capsules, comprising the steps of:

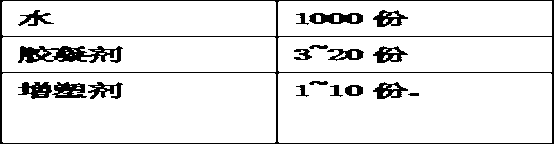

[0042] (1) Weigh 1000g of water, 5g of carrageenan, 10g of gelatin, 1g of pectin, and 1g of glycerin, and add water, plasticizer, and gelling agent to the plastic tank in turn at 73°C, stir until the materials are fully dissolved, and keep warm Degassing.

[0043] (2) The seamless capsules were prepared by co-extrusion method, and the extrusion temperature was 69°C.

[0044] (3) Soak the extruded substantially spherical seamless capsule in paraffin oil for 2 hours.

[0045] (4) Air-dry the soft capsule produced in step (3) for 19 hours in an environment with a temperature of 17°C and a humidity of 35%, and fully dry.

[0046] (5) Wash the capsules with the organic solvent acetone and then place them in a ventilated place at room temperature to air dry.

[0047] The diameter of the soft capsule prepared above is 4.0±0.1mm. The crush strength was 4.7N.

[0048]

Embodiment 3

[0050] A preparation method for finger-extruded friable soft capsules, comprising the steps of:

[0051] (1) Weigh 1000g of water, 5g of carrageenan, 9g of gelatin, 2g of agar, 5g of polyvinyl alcohol, 1g of glycerin, and 1g of sorbitol, and add water, plasticizer, and gelling agent to the plastic tank in sequence at 78°C and filler, stir until the material is fully dissolved, keep warm and debubble.

[0052] (2) The seamless capsules were prepared by co-extrusion method, and the extrusion temperature was 71°C.

[0053] (3) Soak the extruded substantially spherical seamless capsule in paraffin oil for 2 hours.

[0054] (4) Air-dry the soft capsule produced in step (3) for 20 hours in an environment with a temperature of 18°C and a humidity of 41%, and fully dry.

[0055] (5) Wash the capsules with the organic solvent acetone and then place them in a ventilated place at room temperature to air dry.

[0056] The diameter of the soft capsule prepared above is 2.5±0.1mm. The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com