System for accurately measuring flow of engine nozzle

An engine and nozzle technology, applied in the field of engine nozzle flow measurement system, can solve the problems of high requirements for operators, poor precision, high working noise, etc., achieve simple installation and removal, wide application nozzle series, and low working noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

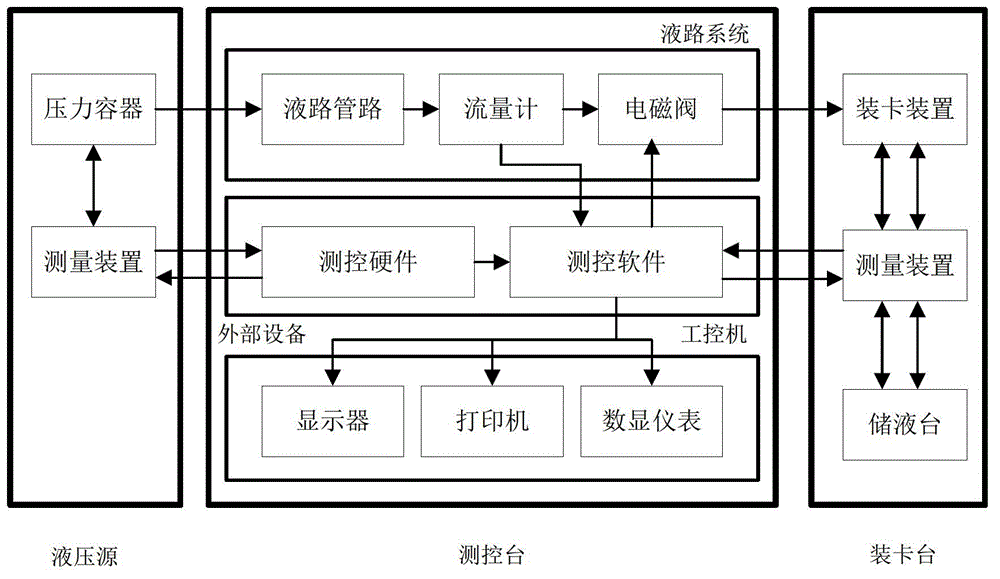

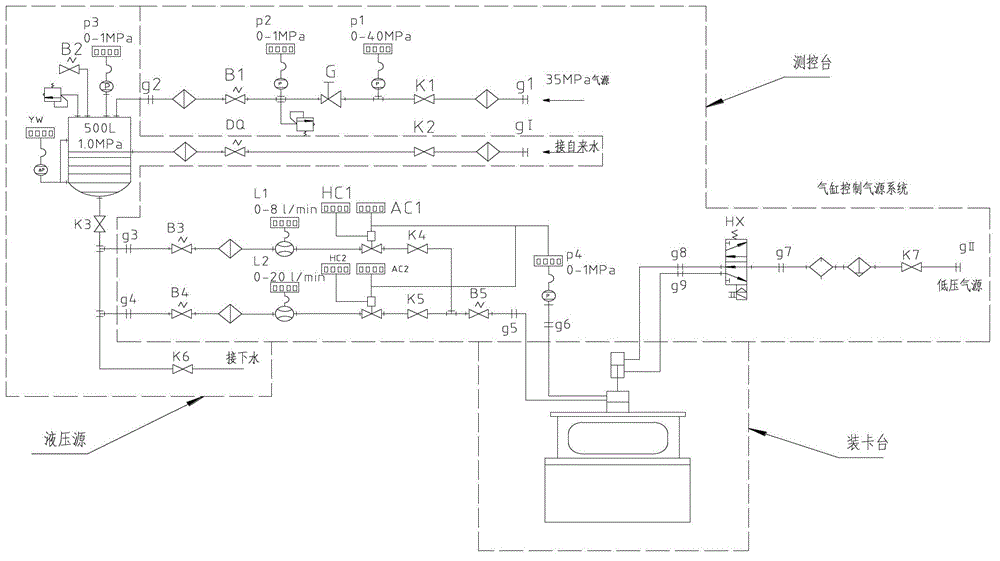

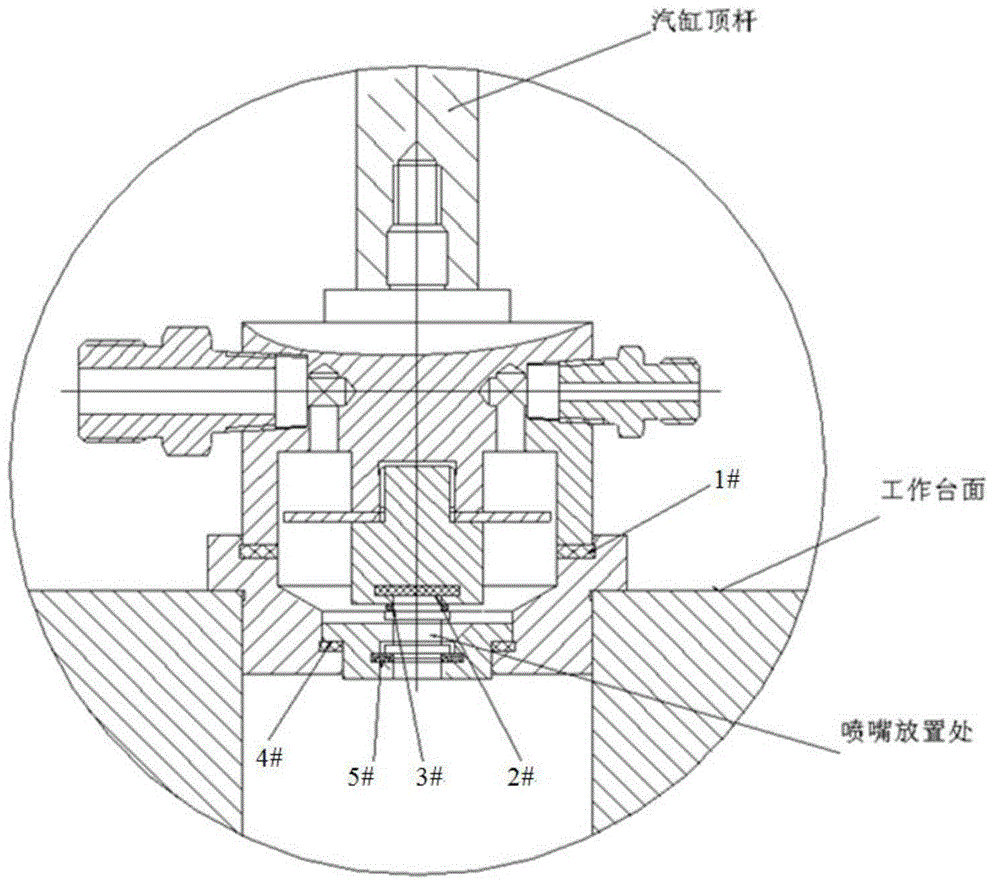

[0021] One of the technical solutions of the present invention is: the nozzle flow precision measurement system is composed of three parts: hydraulic source, measurement and control platform and clamping platform, wherein the hydraulic source provides the liquid flow and pressure required by the system, and the pressure fluid output by the hydraulic source is passed The control valve, pressure sensor, and electromagnetic flowmeter of the station, and finally enter the hydraulic chamber of the loading station. The pressure transmitter in the hydraulic chamber of the loading station and the flow regulating valve at the lower position of the electromagnetic flowmeter of the measurement and control station form a closed-loop control system. The flow regulating valve stabilizes the pressure in the hydraulic chamber of the clamping table to an accurate value. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com