Capacitive pressure transmitter and pressure sensing system

A transmitter, capacitive technology, applied in the field of pressure transmitters and pressure sensing systems, can solve the problems of prolonging the debugging time of the production line, drifting, consuming a lot of manpower, and time-testing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The pressure sensing system of this embodiment includes a capacitive pressure transmitter and a computer, and the computer provides a zero pressure command or a full pressure command for the capacitive pressure transmitter.

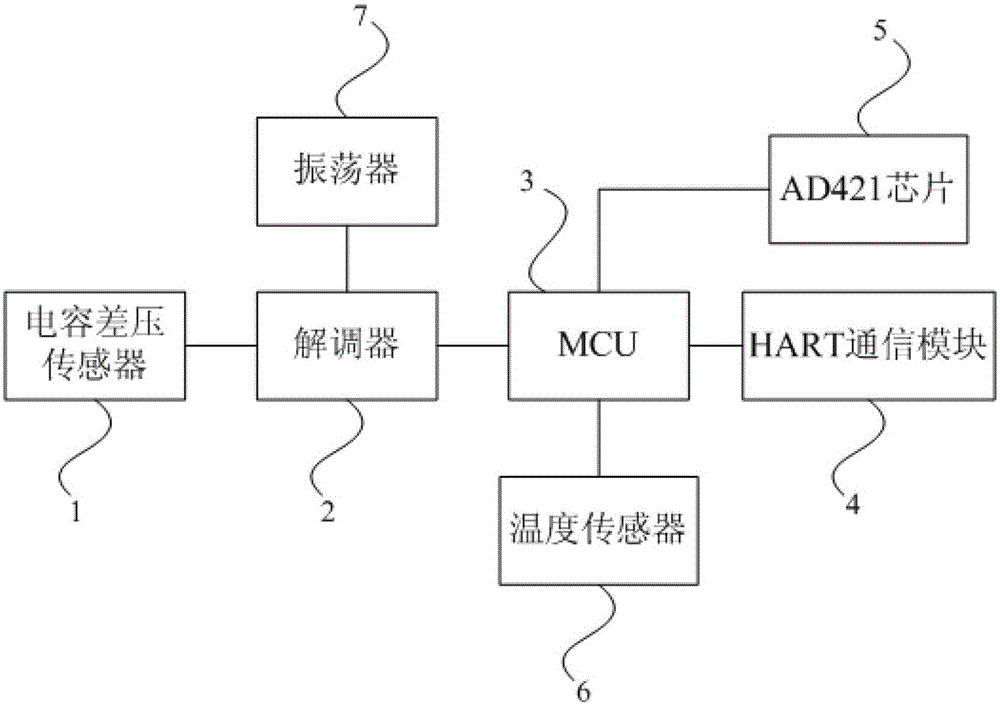

[0038] Specifically, as figure 1 As shown, the capacitive pressure transmitter of this embodiment includes a capacitive differential pressure sensor 1 , a demodulator 2 , an MCU 3 , a HART communication module 4 , an AD421 chip 5 , a temperature sensor 6 and an oscillator 7 .

[0039] Wherein the demodulator 2 is used to convert the capacitance difference generated by the capacitance differential pressure sensor 1 into an analog voltage signal; the MCU3 is used to convert the analog voltage signal output by the demodulator 2 into a digital voltage signal .

[0040] The MCU3 also records the digital voltage signal output by the MCU3 when it receives the zero-voltage command or the full-voltage command based on the zero-voltage command or the full-v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com