Method for modeling and evaluating reliability of three types of functional components of numerical control machine tool

A CNC machine tool, reliability technology, applied in the direction of digital control, simulator, program control, etc., can solve problems such as reliability modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

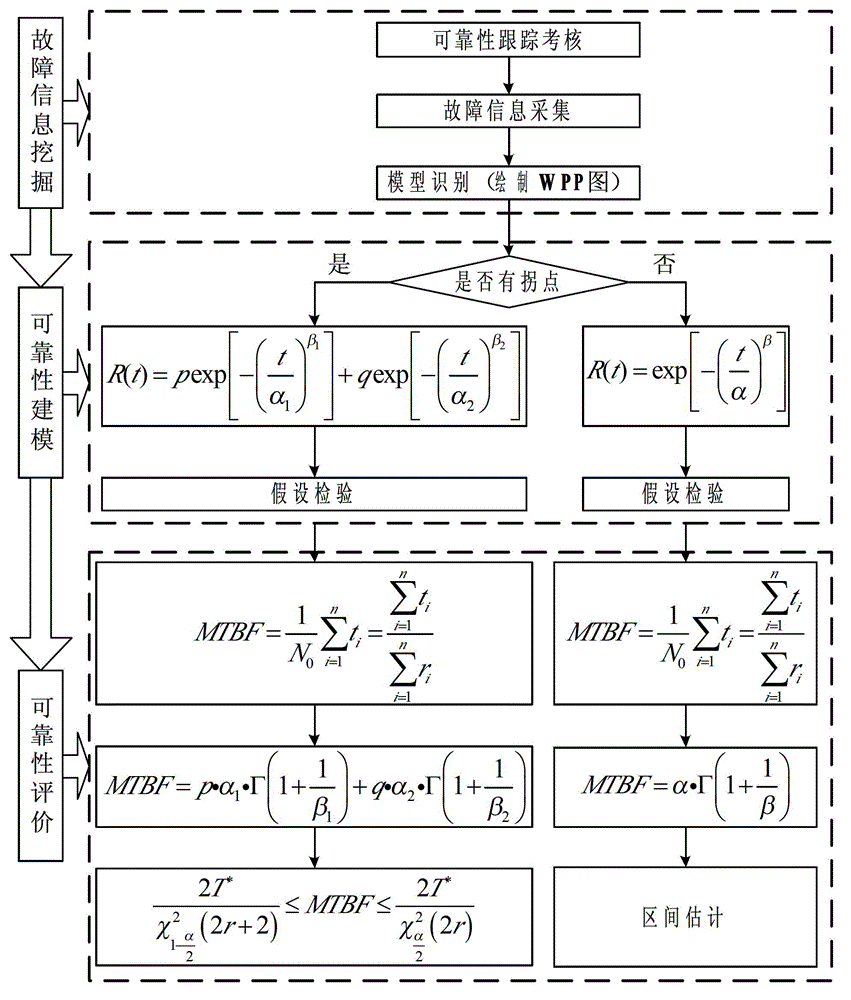

[0105] The primary problem in the reliability analysis of functional components of CNC machine tools is to find a life distribution model that accurately reflects the failure mechanism of functional components and is consistent with the analysis results of failure or failure data. In order to determine the reliability model of the functional components of CNC machine tools, which are composed of multiple components, have fault correlations between components, and have different fault distributions of components or different parameters of the same distribution type, if the traditional reliability model is used The analysis method, simply using the standard Weibull distribution to describe, will have great limitations. The technical problem mainly solved by the present invention is to provide a reliability modeling and evaluation method for functional components such as power servo tool post, tool magazine, manipulator and high-speed spindle unit of CNC machine tools based on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com