Method for solving intrinsic parameters of parabolic catadioptric camera linearly by utilizing three unparallel straight lines in space

A technology of camera internal parameters, parallel straight lines, applied in the field of computer research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

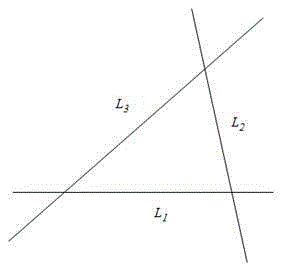

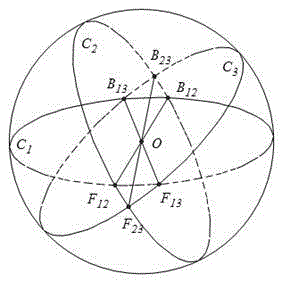

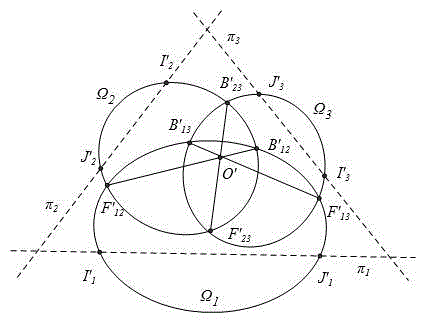

[0033] The invention proposes to use three non-parallel straight lines in space as targets to linearly determine the internal parameters of the parabolic catadioptric camera. The experimental module structure diagram that the present invention adopts is as figure 1 shown. The implementation of the present invention will be described in more detail with an example below.

[0034] The experimental template used by the parabolic catadioptric camera calibration method based on three non-parallel straight lines in space is three non-parallel straight lines in space, such as figure 1 shown. The three straight lines are , , , using the method in the present invention to calibrate the parabolic catadioptric camera used in the experiment, the specific steps are as follows:

[0035] 1. Fit the curve equation of the straight line projection in the image

[0036] The image resolution that the present invention adopts is 640 * 480 pixels, takes 1 experimental picture with the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com