Planar array paster-type low-energy-consumption environment-friendly high-precision packaging mould for integrated circuit

A planar array, integrated circuit technology, applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve problems such as large warpage, gas accumulation, and unsatisfactory filling, and achieve high production efficiency, environmental protection, and production costs. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The structure of the present invention will be further described below with reference to the accompanying drawings.

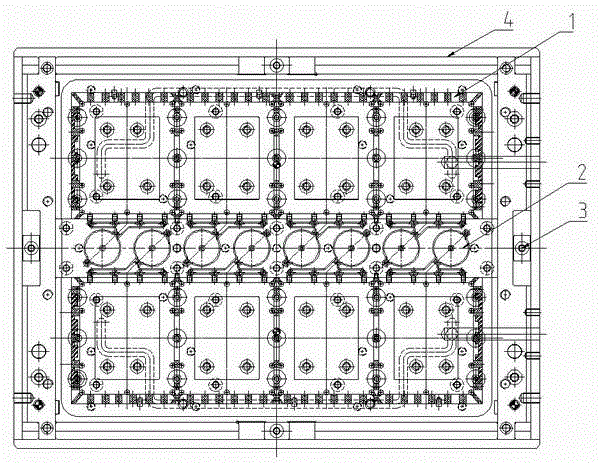

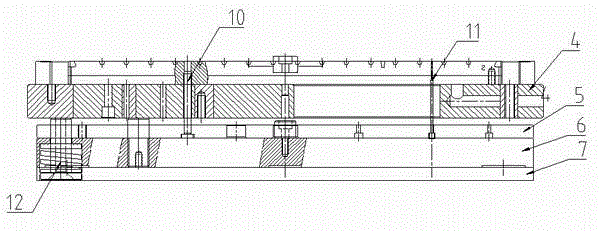

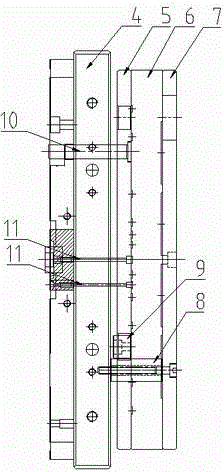

[0034] figure 1 , 2 , 3 shows a structural diagram of an upper mold box of a high-precision integrated circuit packaging mold.

[0035] Figure 4 , 5 , 6 shows a structural diagram of the lower mold box of a high-precision integrated circuit packaging mold.

[0036] Figure 7 It shows a mold clamping structure diagram of an upper mold box and a lower mold box of a high-precision integrated circuit packaging mold.

[0037] Figure 8 , 9 10 shows a structure diagram of an upper mold cavity of a high-precision integrated circuit packaging mold.

[0038] In the figure, an upper mold cavity 1, an upper mold injection block 2, and an upper mold positioning block 3 are installed on the upper mold box 4, and a lower mold cavity 13, a lower mold cavity block 14, and a lower mold cavity 19 are installed on the lower mold box 19. Injection block 15, lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com