Ultrasonic motor dual pulse-width modulation (PWM) power drive topological structure

An ultrasonic motor, power drive technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of low energy conversion efficiency, poor matching effect, dynamic The impact of impedance is large, so as to achieve the effect of improving energy conversion efficiency and stabilizing output impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

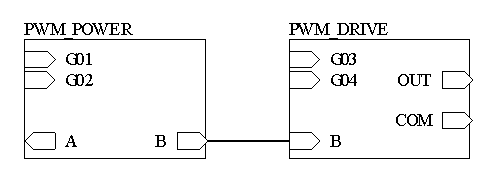

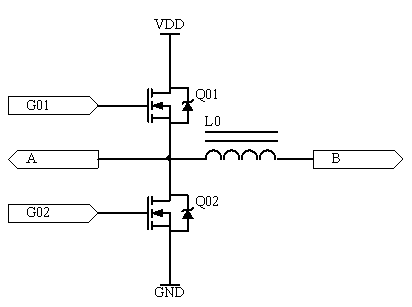

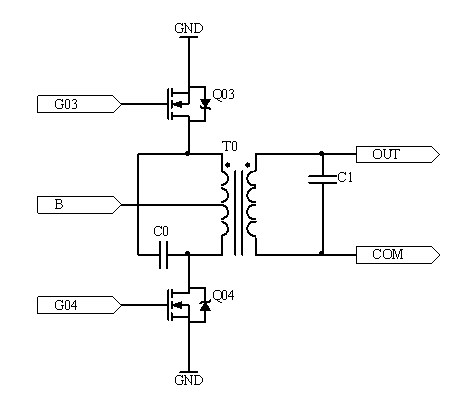

[0026] The ultrasonic motor dual PWM power drive topology of the present invention includes two PWM components of constant current power supply PWM_POWER and power coupling PWM_DRIVE, such as figure 1 shown. Constant current power supply PWM_POWER by figure 2 The shown power tubes Q01, Q02 and inductor L0 are composed. Power coupled PWM_DRIVE by image 3 The shown power tubes Q03, Q04, C0, C1 and variable transformer T0 are composed.

[0027] In the constant current power supply PWM_POWER, the drain of the power transistor Q01 is connected to the positive pole of the DC power supply VDD, and the source of the power transistor Q02 is connected to the negative pole of the DC power supply GND. The source of the power transistor Q01 is connected to the drain of the power transistor Q02 to form a test point A. The power transistor Q01 is controlled by the PWM drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com