Built-in ultrahigh-frequency antenna sensor for switch cabinet

A switch cabinet and ultra-high frequency technology, applied in the structural field of partial discharge ultra-high frequency antenna sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

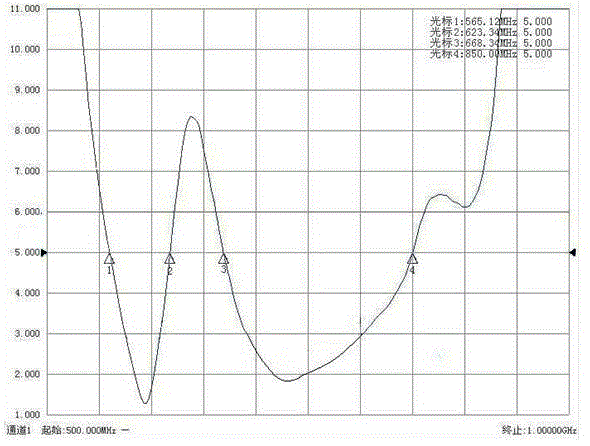

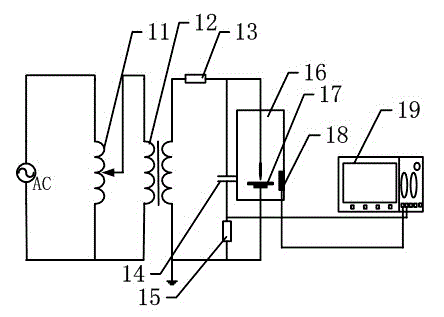

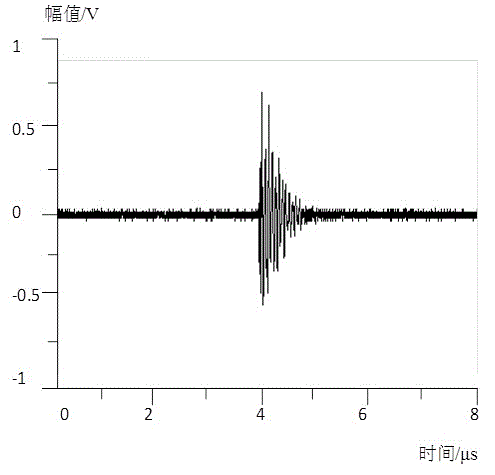

[0030] Such as figure 1 , 2 As shown, a switchgear built-in UHF antenna sensor, including antenna radiation layer 1, feeding probe 6, dielectric layer 2, support plate 5, air dielectric layer 3, coaxial cable 7, coaxial connector 8, grounding Layer 4.

[0031]The material of the dielectric layer 2 is epoxy resin with a relative permittivity of 4.8. The shape of the dielectric layer is a square with a side length of 200 mm and a thickness of 5 mm, and is used as an insulating layer and a supporting member of the antenna sensor of the present invention. On the periphery of the dielectric layer 2 , two screw holes are uniformly arranged respectively for fixing the support plate 5 . Four support plates 5 are respectively fixed on the lower end surfaces around the dielectric layer 2 by bolts. Each support plate 5 has a thickness of 3 mm, a height of 20 mm, and a length equal to the side length of the dielectric layer 2 . The support plate 5 , the dielectric layer 2 and the gr...

Embodiment 2

[0036] A built-in UHF antenna sensor in a switchgear is the same as in Embodiment 1, wherein the material of the dielectric layer 2 is epoxy resin with a relative permittivity of 2.5. Its side length is 100 mm and its thickness is 1 mm. There are four screw holes on the dielectric layer 2 for fixing the support plate 5 . The support plate 5 has a thickness of 2 mm and a height of 5 mm. The antenna radiating layer 1 is made of aluminum, with a peripheral side length of 98 mm and a thickness of 5 μm. The surface is plated with a tin layer with a thickness of 3 μm. The aperture of the feed point 10 is 0.2 mm. The material of the feed probe 6 is aluminum, and the length is 4 mm. The material 4 of the ground layer is aluminum with a side length of 120 mm and a thickness of 1 mm. The number of screw holes on the ground layer 4 for fixing the support plate 5 is 4, and the ground layer 4 is used for fixing the antenna sensor to the switch cabinet. The number of screw holes on the ...

Embodiment 3

[0038] A built-in UHF antenna sensor in a switchgear is the same as in Embodiment 1, wherein the material of the dielectric layer 2 is epoxy resin with a relative dielectric constant of 10.2. It has a side length of 250 mm and a thickness of 3 mm. There are 8 screw holes on the dielectric layer 2 for fixing the support plate 5 . The supporting plate 5 has a thickness of 10 mm and a height of 15 mm. The material of the antenna radiation layer 1 is silver, the outer side length is 240mm, and the thickness is 50μm. The surface is plated with a tin layer with a thickness of 12 μm. The aperture of the feed point 10 is 2 mm. The material of the feed probe 6 is silver, and the length is 14 mm. The material 4 of the ground layer is silver, with a side length of 270 mm and a thickness of 5 mm. The number of screw holes on the ground layer 4 for fixing the support plate 5 is 8, and the ground layer 4 is used for fixing the antenna sensor to the switch cabinet. The number of screw ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com