Laminating method of printed circuit board with ultra-thickness copper foil on the surface of core plate

A technology for printed circuit boards and core boards, which is applied in the fields of printed circuits, printed circuit manufacturing, electrical components, etc., and can solve the problem of printed circuit board explosion or delamination, poor fluidity of prepreg, and difficulty in filling etching grooves and other issues to achieve the effect of saving materials, improving electrical reliability, and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

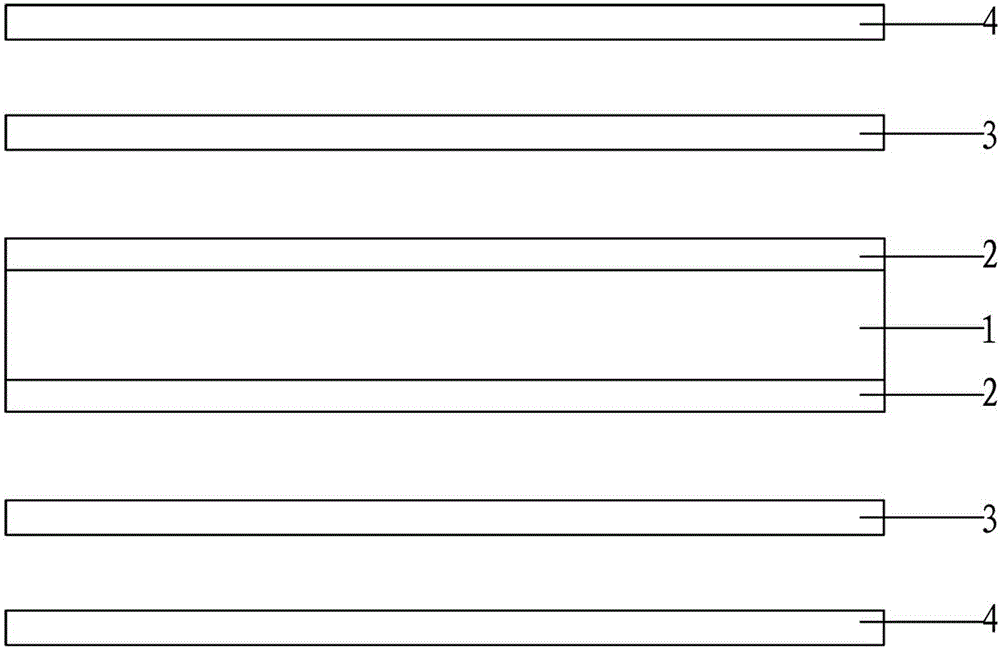

[0011] Example, combined with figure 1 , a method for laminating printed circuit boards with super-thick copper foil on the surface of the core board. A. The surface of the core board 1 is provided with a copper foil 2 with a thickness of over 140 microns. The copper foil 2 is etched; B is on the surface of the copper foil 2. Fill the etching tank with prepreg powder; C heat the core board 1 after step B to dissolve the prepreg powder and prevent it from falling from the etching tank. The heating temperature is 75-100°C and the heating time is 1-3 minutes; D, and then rapidly cool down to solidify the prepreg powder; E, place a prepreg layer 3 on the surface of the core board, and place a copper foil layer 4 on the surface of the prepreg layer 3; F press the E step by pressing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com