Airborne small-scale liquid cooling device

A liquid-cooled, small-sized technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of not meeting the heat dissipation requirements of electronic equipment, reducing the heat dissipation efficiency of electronic components, unable to use the environmental control liquid cooling system, etc. It is easy to realize and install and use, and the cooling effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

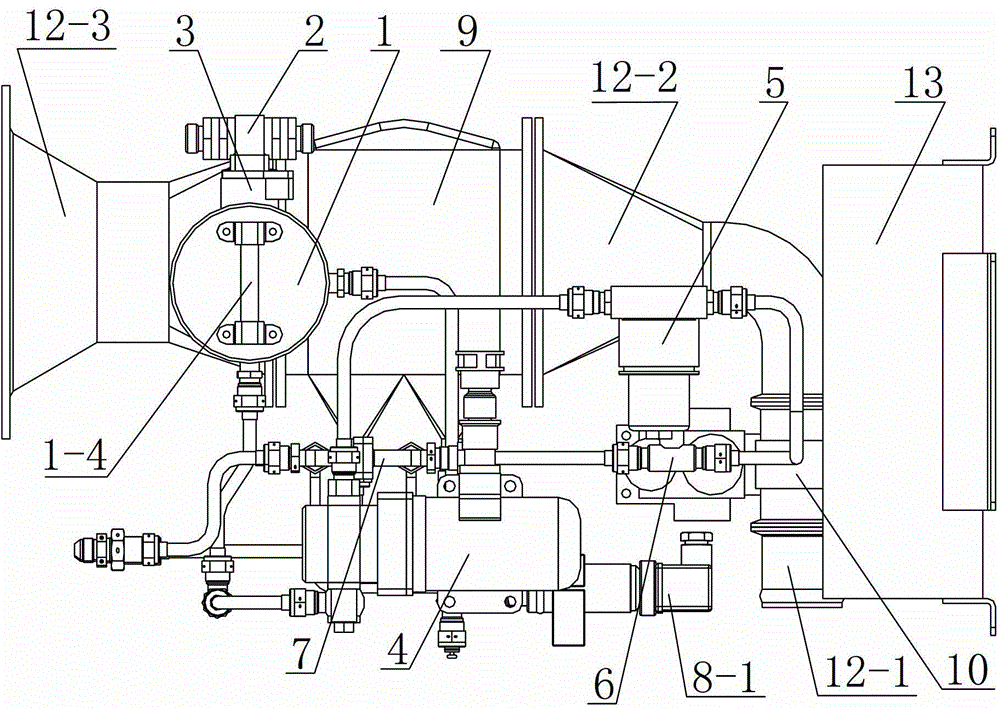

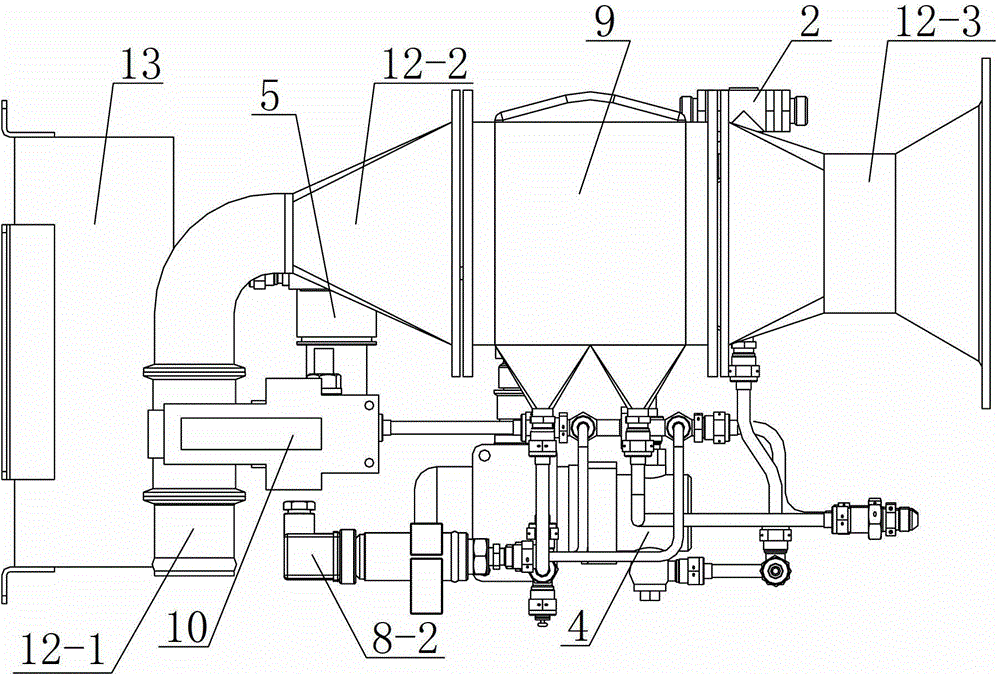

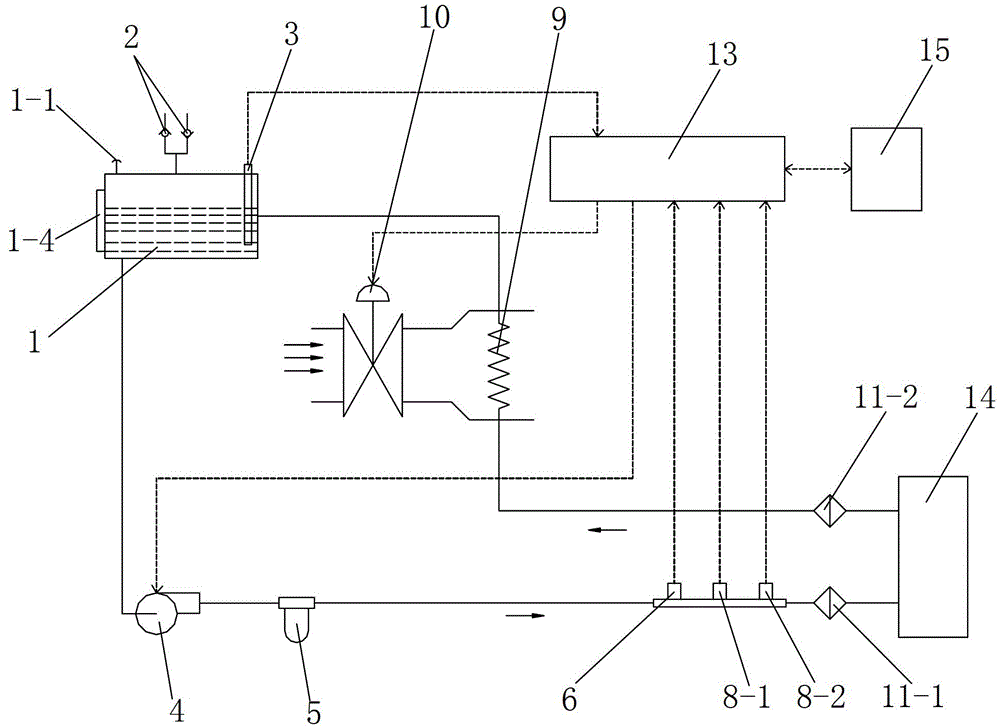

[0048] Such as Figure 1 to Figure 9 As shown, the present invention includes a liquid cooling module and an intelligent control module 13 for collecting and transmitting working parameters of the liquid cooling module in real time and controlling the liquid cooling module. The liquid cooling module includes an expansion tank 1 and a liquid pump 4 , filter 5, flow measuring device 7, gas-liquid heat exchanger 9 and electric valve 10, described liquid pump 4 and electric valve 10 all join with described intelligent control module 13; Described expansion tank 1 is provided with Filling port 1-1, expansion tank liquid inlet pipe seat 1-2 and expansion tank liquid outlet pipe seat 1-3, the liquid pump 4 is provided with a liquid pump liquid inlet pipe seat 4-1 and a liquid pump outlet pipe Seat 4-2, the filter 5 is provided with a filter inlet pipe seat 5-1 and a filter outlet pipe seat 5-2, and the flow measurement device 7 includes a flow measurement tube 7-5 connected to the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com