Processing method for effectively reducing anisotropy of cold-rolled titanium tape

An anisotropy and processing method technology, applied in metal rolling and other directions, can solve problems such as poor symmetry, less slip system, and poor deep drawing performance, and achieve reduced anisotropy, improved flatness, and processing and forming sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

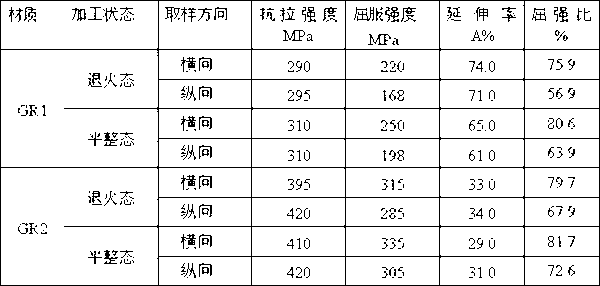

[0030] a The 0.6*1250*C mm cold-rolled GR1 titanium coil with a rolling deformation of 80% is subjected to complete recrystallization annealing, the annealing temperature is 720°C, and the holding time is calculated as 7 hours and 20 minutes. The grain size of the titanium coil after annealing About 53.4um.

[0031] b. Send the titanium coil into an ordinary cold rolling mill, the crown of the work roll is 0.03mm, the rolling speed is 15-50m / min, and the uncoiling unit tension is 2-10kg / mm 2 , Rewinding unit tension 3~15kg / mm 2 , Under the condition that the rolling force is 100-200 tons, through the constant rolling force control mode, the work roll on the ordinary cold rolling mill is used to directly dry-level the pure titanium coil, and the reduction is not greater than 5um.

[0032] c. After annealing according to the above requirements, the difference in transverse and longitudinal yield strength ratio of titanium coils is about 27%, and the difference in transverse and...

Embodiment 2

[0034] a The 0.5*1250*C mm cold-rolled GR1 titanium coil with a rolling deformation of 80% is subjected to complete recrystallization annealing, the annealing temperature is 720°C, and the holding time is calculated as 7 hours and 10 minutes. The grain size of the titanium coil after annealing About 53.4um.

[0035] b. Send the titanium coil into an ordinary cold rolling mill, the crown of the work roll is 0.03mm, the rolling speed is 15-50m / min, and the uncoiling unit tension is 2-10kg / mm 2 , Rewinding unit tension 3~15kg / mm 2 , Under the condition that the rolling force is 100-200 tons, through the constant rolling force control mode, the work roll on the ordinary cold rolling mill is used to directly dry-level the pure titanium coil, and the reduction is not greater than 5um.

[0036] c. After annealing according to the above requirements, the difference in transverse and longitudinal yield strength ratio of titanium coils is about 29%, and the difference in transverse and...

Embodiment 3

[0038]a The 1.01*1250*C mm cold-rolled GR1 titanium coil with a rolling deformation of 50% is subjected to complete recrystallization annealing, the annealing temperature is 650°C, and the holding time is calculated as 7 hours and 40 minutes. The grain size of the titanium coil after annealing About 44.9um.

[0039] b. Send the titanium coil into an ordinary cold rolling mill, the crown of the work roll is 0.03mm, the rolling speed is 15-50m / min, and the uncoiling unit tension is 2-10kg / mm 2 , Rewinding unit tension 3~15kg / mm 2 , under the condition that the rolling force is 100-200 tons, through the constant rolling force control mode, the work roll on the ordinary cold rolling mill is used to directly dry-level the pure titanium coil, and the reduction is not more than 15um.

[0040] c. After annealing according to the above requirements, the difference between the transverse and longitudinal yield ratios of titanium coils is about 23%, and the difference between the transv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com