Construction method for improving centring accuracy of racks of steel tube perforating machines

A construction method and piercing machine technology, which are applied to metal rolling stands, metal rolling mill stands, manufacturing tools, etc., can solve the problems of large crane weight, time-consuming and laborious, low stand centering accuracy, etc. Construction cost, safe and practical operation, and the effect of improving installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

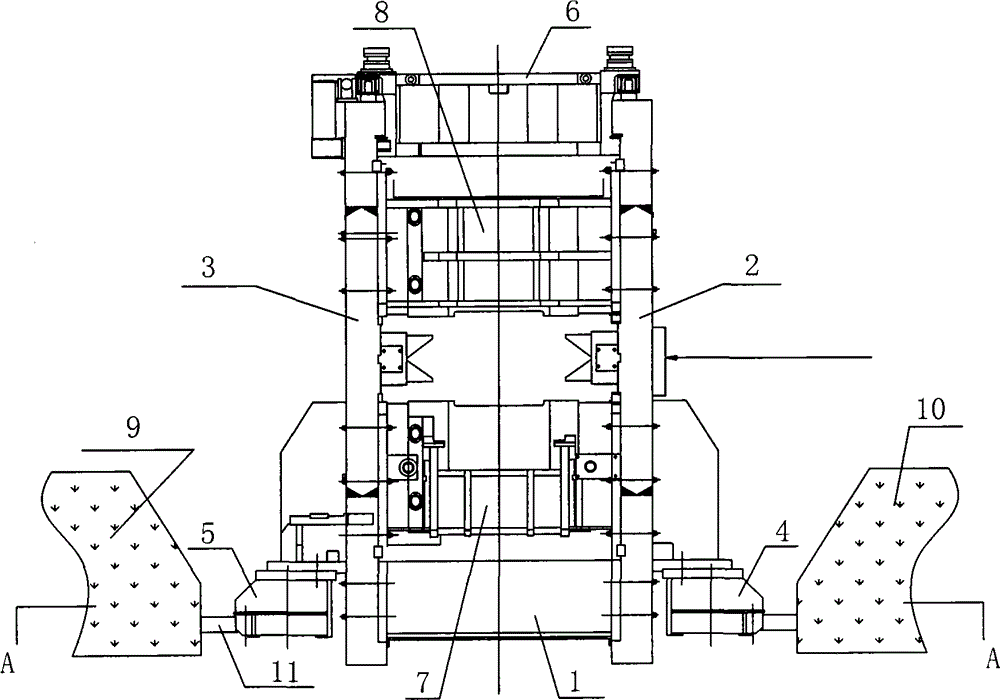

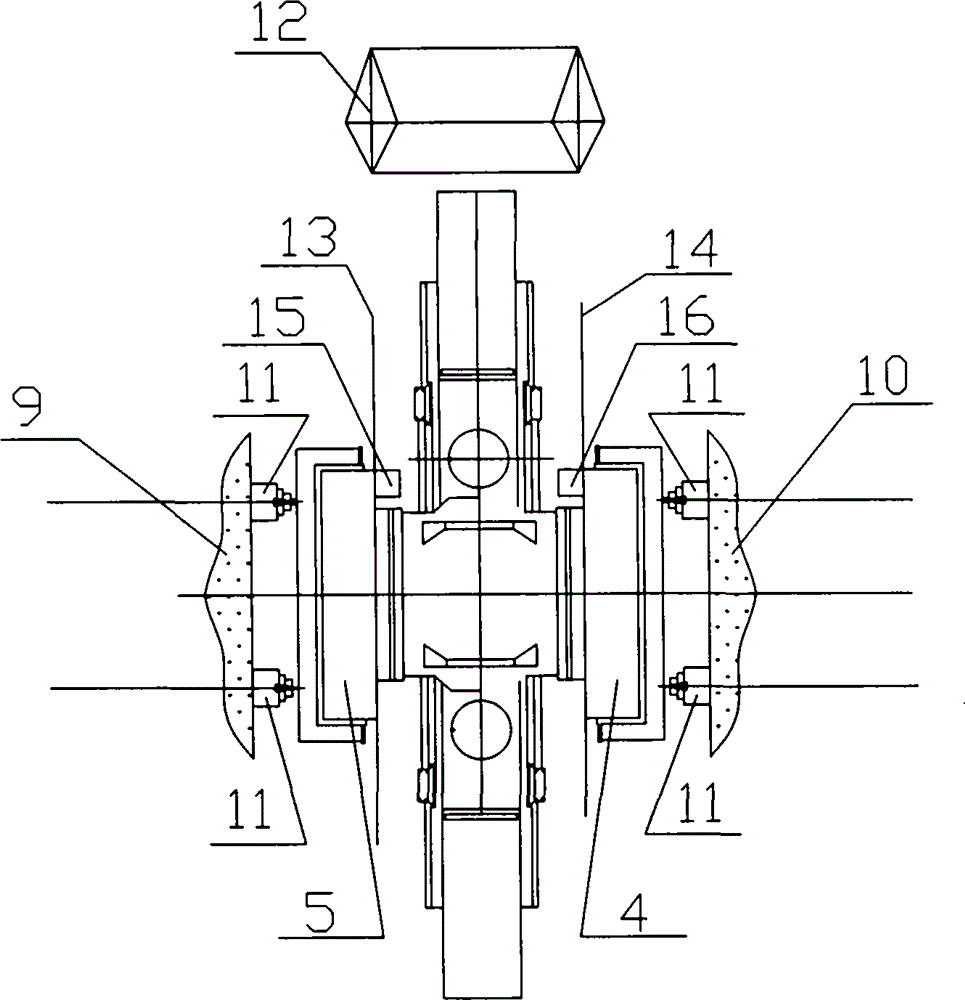

[0013] Referring to the accompanying drawings, in Baotou Steel's seamless φ159 continuous rolling steel pipe production line project, the installation of the piercing machine is taken as an example to describe the present invention:

[0014] The piercing machine is arranged between the 12th and 13th lines of the BC span of the factory building, on a 13-meter reinforced concrete platform. The piercing machine body equipment is designed and manufactured by German SMS group (SMS group). The main frame of the punching machine weighs about 180t, the main machine weighs 260,000kg, and the overall dimensions are 4710mm×3624mm×7244mm. The piercing machine equipment is delivered in parts and assembled on site.

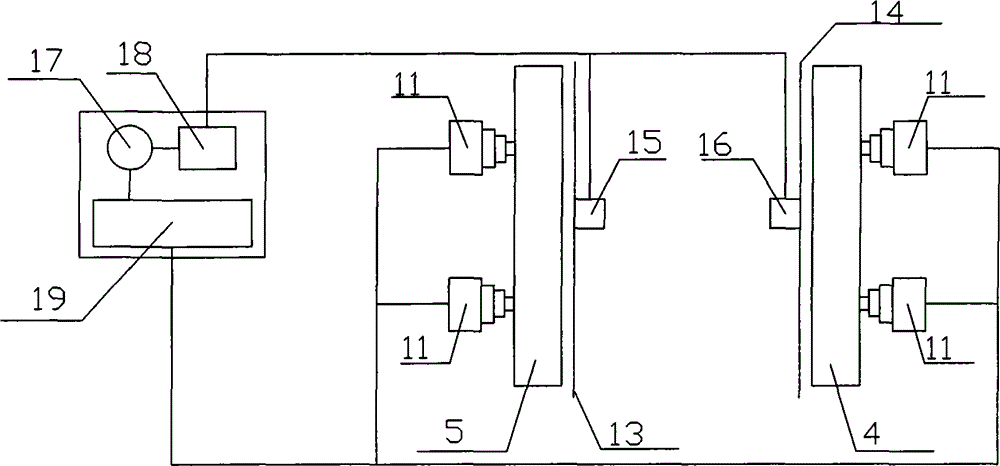

[0015] 1. Preparatory work before the construction method: first install the left and right bases 5 and 4 of the punching machine, and leave the size of the T-shaped key connecting the frame and internal components (center distance + key height). Then the left and right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com