Forging process of automotive besides-star wheel

A kind of alien wheel and process technology, applied in the direction of wheels, vehicle parts, metal processing equipment, etc., can solve the problems of high production cost, reduce the utilization rate of raw materials, waste production time, etc., to improve the utilization rate of materials, reduce production costs, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

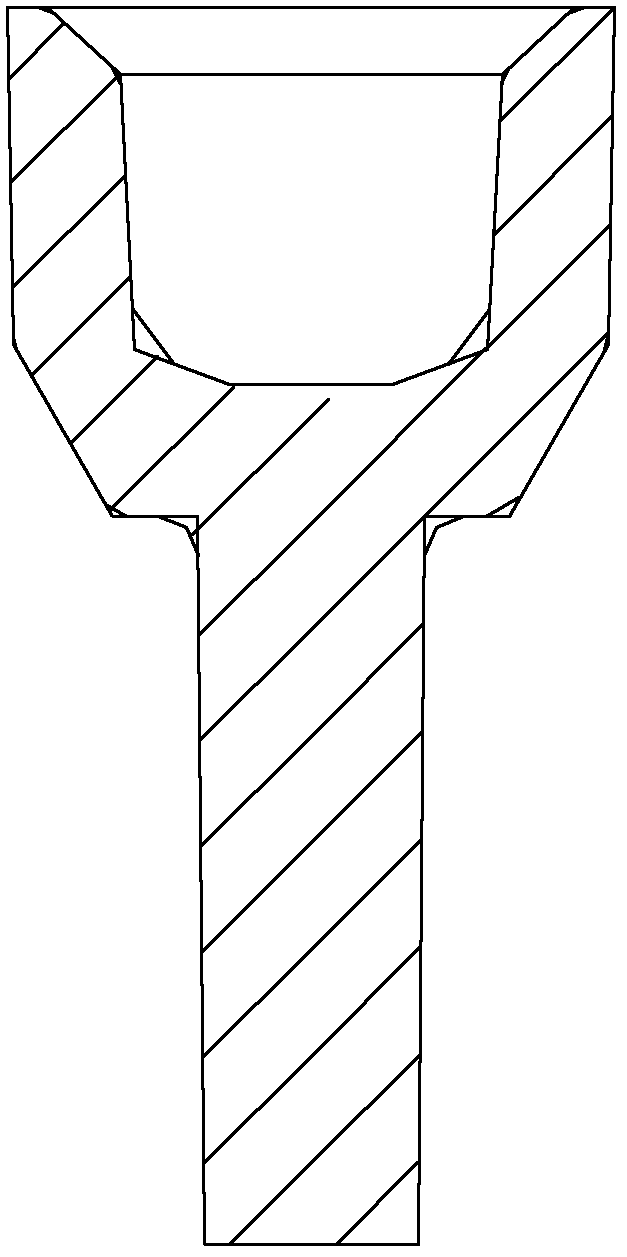

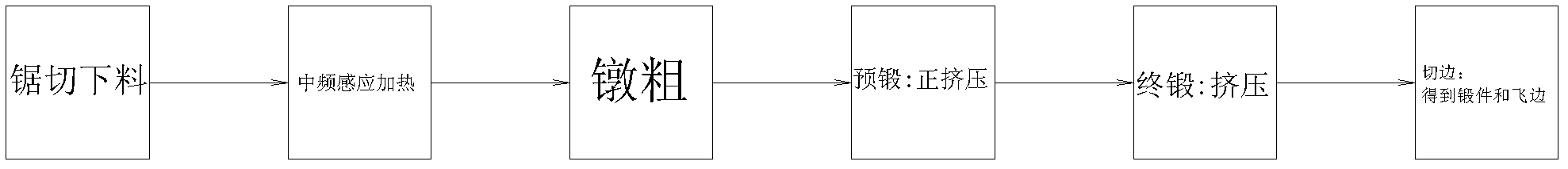

[0024] as attached figure 1 , 2 As shown in and 3, traditionally in the forging process of the automotive outer star wheel, no matter the open die forging process or the closed die forging process is adopted, considering the flow characteristics of the metal material, since the metal material has a In the process of receiving tangential stress, in order to ensure the internal stress balance of metal raw materials, it is generally not necessary to make the raw materials flow in both forward and reverse directions at the same time in the same process.

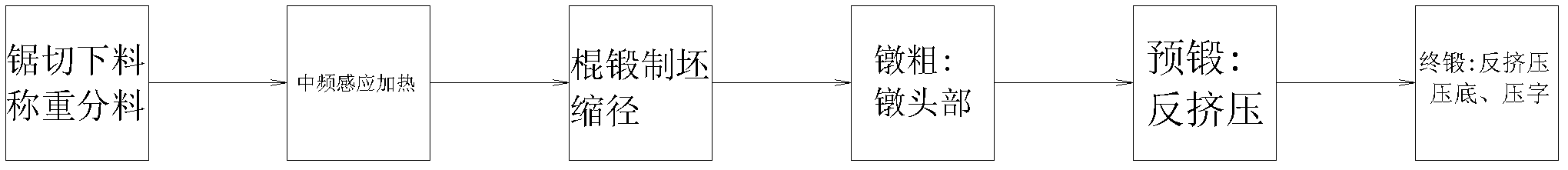

[0025] as attached Figure 4 , 5 As shown in 6 and 6, a forging process for an automotive alien wheel includes the following steps: sawing and blanking process, intermediate frequency induction heating process, upsetting process at the head and entrance, composite extrusion pre-forging process, composite extrusion Final forging process. The sawing and blanking process can be completed on a traditional sawing machine. The heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com