Exhaust system of large power forklift

An exhaust system and high-power technology, which is applied to vehicle components, gas intake of power plant, power plant, etc., can solve the difficult layout of exhaust system rich in high-temperature gas, limited continuous working time for one refueling, and affect noise reduction. The distance between the fuel tank and the fuel tank, etc., achieves the effect of simple and convenient daily maintenance and cleaning, increased continuous working time, and good exhaust effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

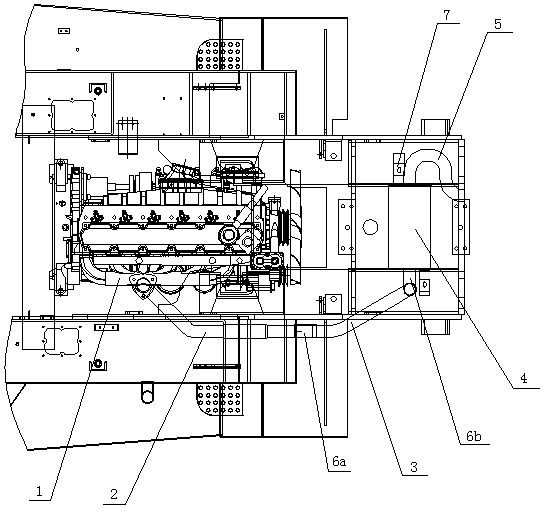

[0020] See figure 1 , a high-power forklift exhaust system, including an exhaust manifold 1, an exhaust pipe 2, a connecting pipe 3, a muffler 4 and a tail pipe 5 connected in sequence, and the exhaust pipe 2 is connected to the exhaust manifold through a flange On the side of the pipe 1, the air outlet of the exhaust pipe 2 is connected to the connecting pipe 3 through the first clamp 6a. The muffler 4 is connected to the tailpipe 5, and the muffler 4 is connected to the tail frame of the car body through rubber pads, bolts, nuts, flat pads and spring pads 7; the exhaust pipe 2 and the connecting pipe 3 are threaded pipes, and the exhaust pipe 2 and the connecting pipe 3 are arranged parallel to the side of the exhaust manifold 1 and connected through the exhaust pipe.

[0021] Since the connection between the engine and the car body is made of rubber shock absorbers, and the connection between the muffler and the car body is also made of rubber shock absorbers, the exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com