ship bionic propeller

A technology for propellers and ships, applied in the direction of rotating propellers, rotary propellers, etc., can solve the problems of reduced propeller performance, reduced propeller efficiency, and increased hull pulsation pressure, and achieves the effects of simple structure, improved efficiency, and reduced cavitation noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

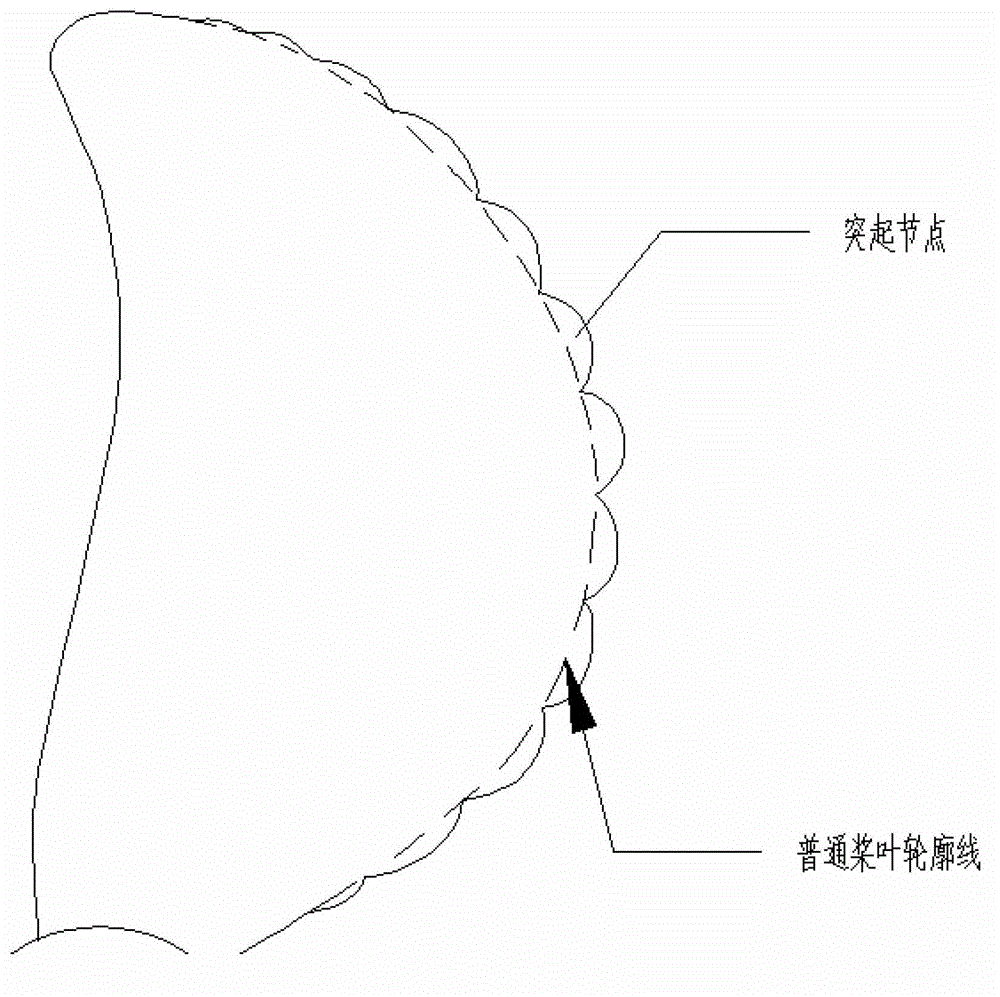

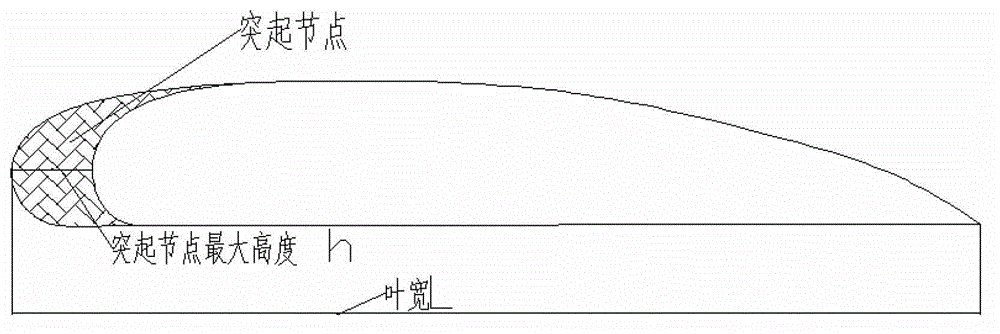

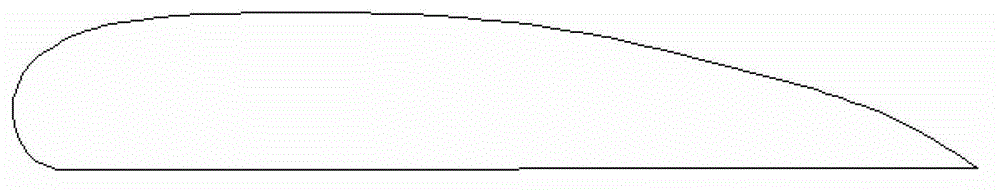

[0016] to combine Figure 1~3 , the present invention is a novel bionic propeller, the novelty of which is that the leading edge of the blade is designed as a concave-convex leading edge structure by imitating the protruding structure of the pectoral fin of the humpback whale.

[0017] The concave-convex leading edge structure is composed of 12 protruding nodes with similar shapes and different sizes. The arrangement of the protruding nodes in the leading edge is as follows: the protruding node in the middle of the leading edge is the largest, and the protruding degree of the remaining protruding nodes decreases along the leading edge to both sides, and smoothly transitions to the tip and hub. like figure 1 Compared with the common propeller, the new propeller has a larger blade area and can generate greater thrust under a certain main engine power.

[0018] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com