Online steering device of double-anode casting carbon block conveying system

A conveying system and steering device technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as difficult maintenance, frequent faults of steering devices, and restrictions on the normal progress of automatic casting production, so as to reduce labor intensity and improve equipment operation rate, the effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

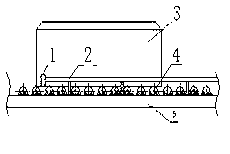

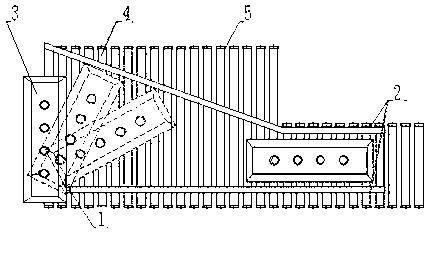

[0016] An online steering device for a double anode casting carbon block conveying system, which includes a conveying chain support 5, and a conveying roller table 4 matched on the conveying chain support 5, such as figure 1 Shown: the support steel bar 1 is fixed on the left side of the conveying roller table 4, and a guide device 2 is respectively installed on the upper part of the conveying roller table 4 both sides.

[0017] The guide device 2 is assembled from a steel pipe and an angle steel supporting the steel pipe, and its specific structure is: a Φ75mm steel pipe is used as a guide, and a 50mm angle steel is used as a support and a reinforcing rib.

[0018] The supporting steel rod 1 is a Φ60mm*400mm steel rod, which fixes the left side of the conveying roller table 4 at a distance of 750mm from the center line of the conveying roller table 4 .

[0019] The guide device 2 is at a height of 150 mm from the plane of the conveying roller table 4 on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com