Automatic quartz crucible material feeding molding system

A quartz crucible and automatic feeding technology, applied in the field of solar energy applications, can solve the problems of large impact on the quality of the crucible, the material being loaded is not very uniform, and the work efficiency is low, saving labor, accurate feeding quality, and improving products. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

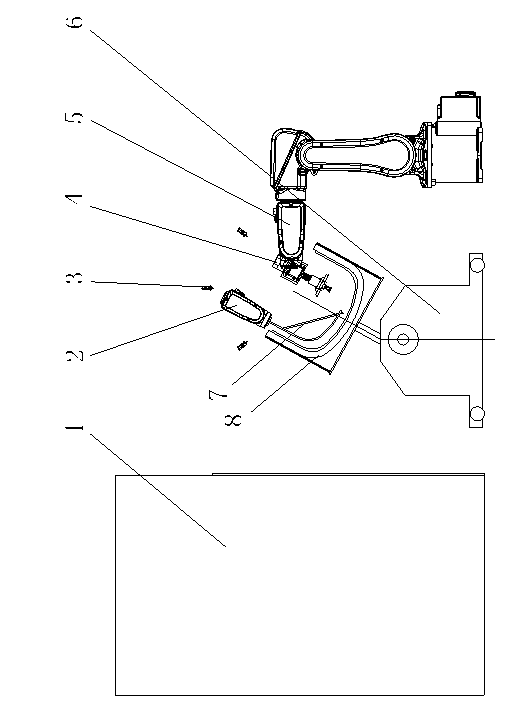

[0015] As shown in the accompanying drawings: a quartz crucible automatic feeding molding system, including a rotary crucible melting furnace 6, a quartz crucible melting room 1, a laser type position calculation photoelectric cell, an optical positioning camera 3, a pneumatic charging machine 4, Feeding manipulator 5, quartz crucible molding manipulator 2 and molding rod 7, quartz crucible melting room 1 and feeding manipulator 5 are respectively arranged on both sides of the said rotary crucible melting furnace 6, and pneumatic loading manipulator 5 is installed on the feeding manipulator 5. A feeder 4, a laser-type position calculation photocell and an optical positioning camera 3 are arranged above the rotary crucible melting furnace 6, a quartz crucible 8 is installed in the rotary crucible melting furnace 6, and a molding rod 7 is arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com