Nitrogen closed-loop cyclic regeneration type propylene dehydration method and device

A closed-loop, regenerative technology, applied in climate sustainability, chemical industry, organic chemistry, etc., can solve problems such as energy consumption, environmental pollution, waste, etc., and achieve the effect of eliminating danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

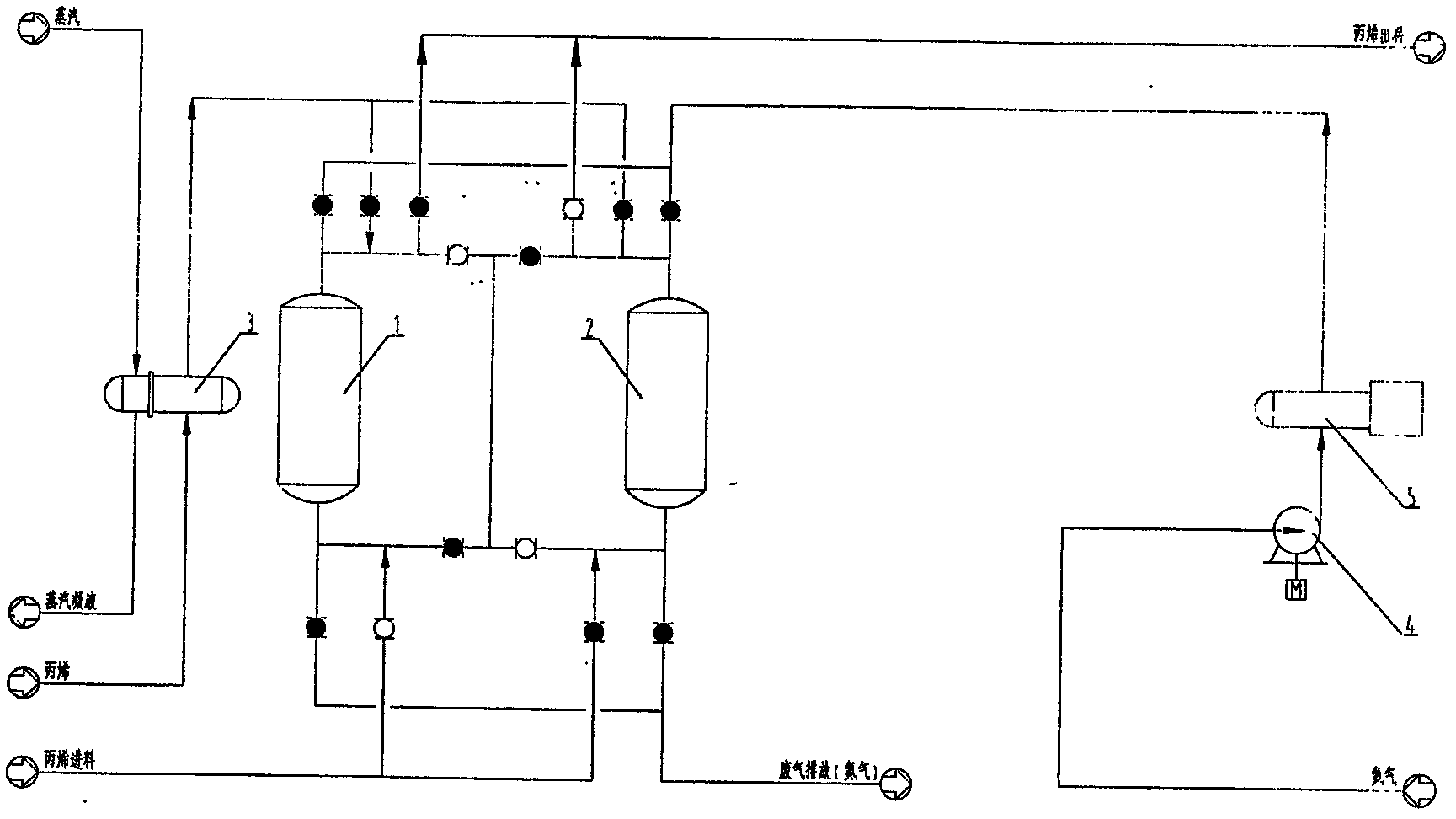

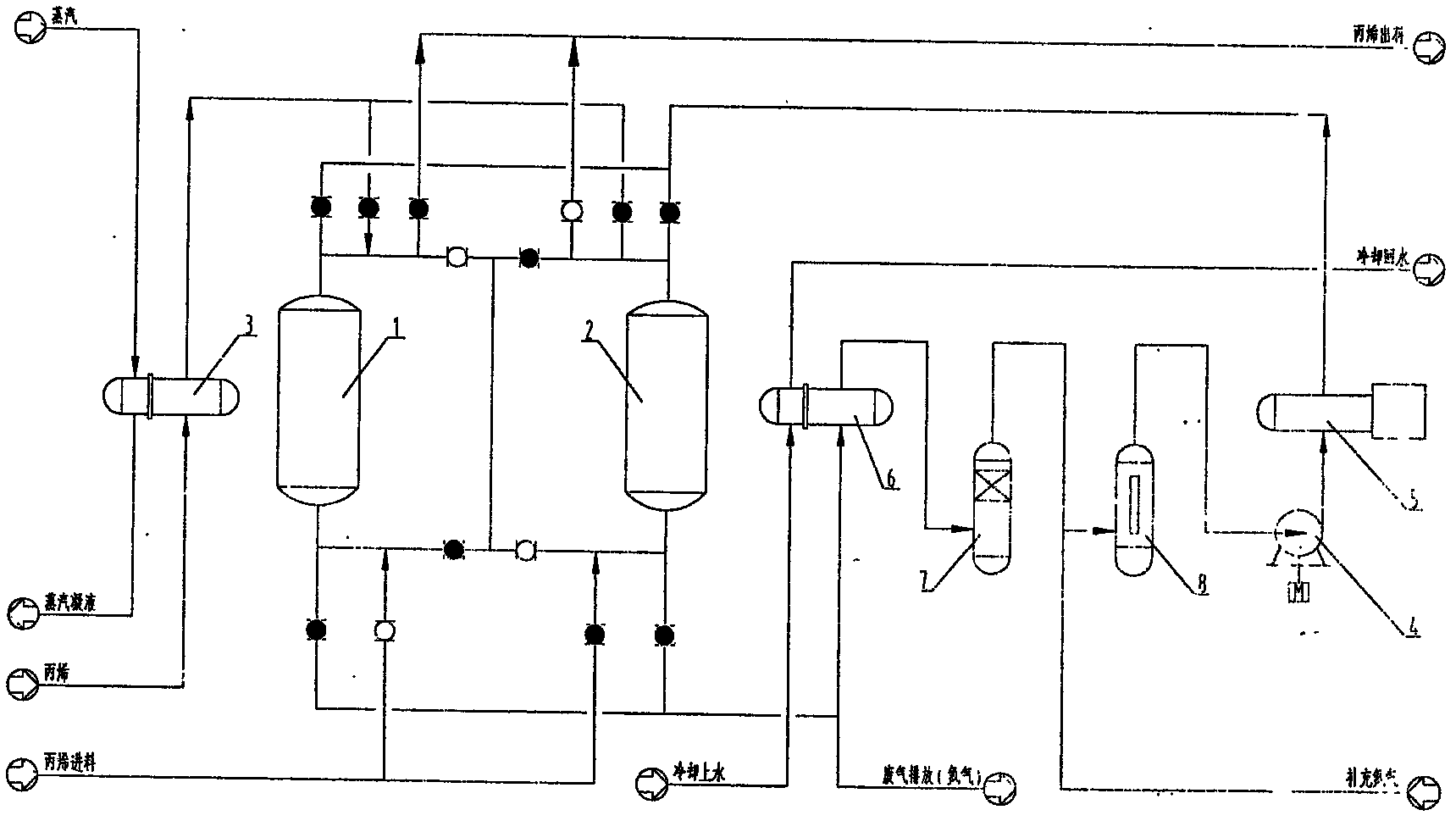

[0031] combined with figure 2 , the technical process of the present invention is described as follows:

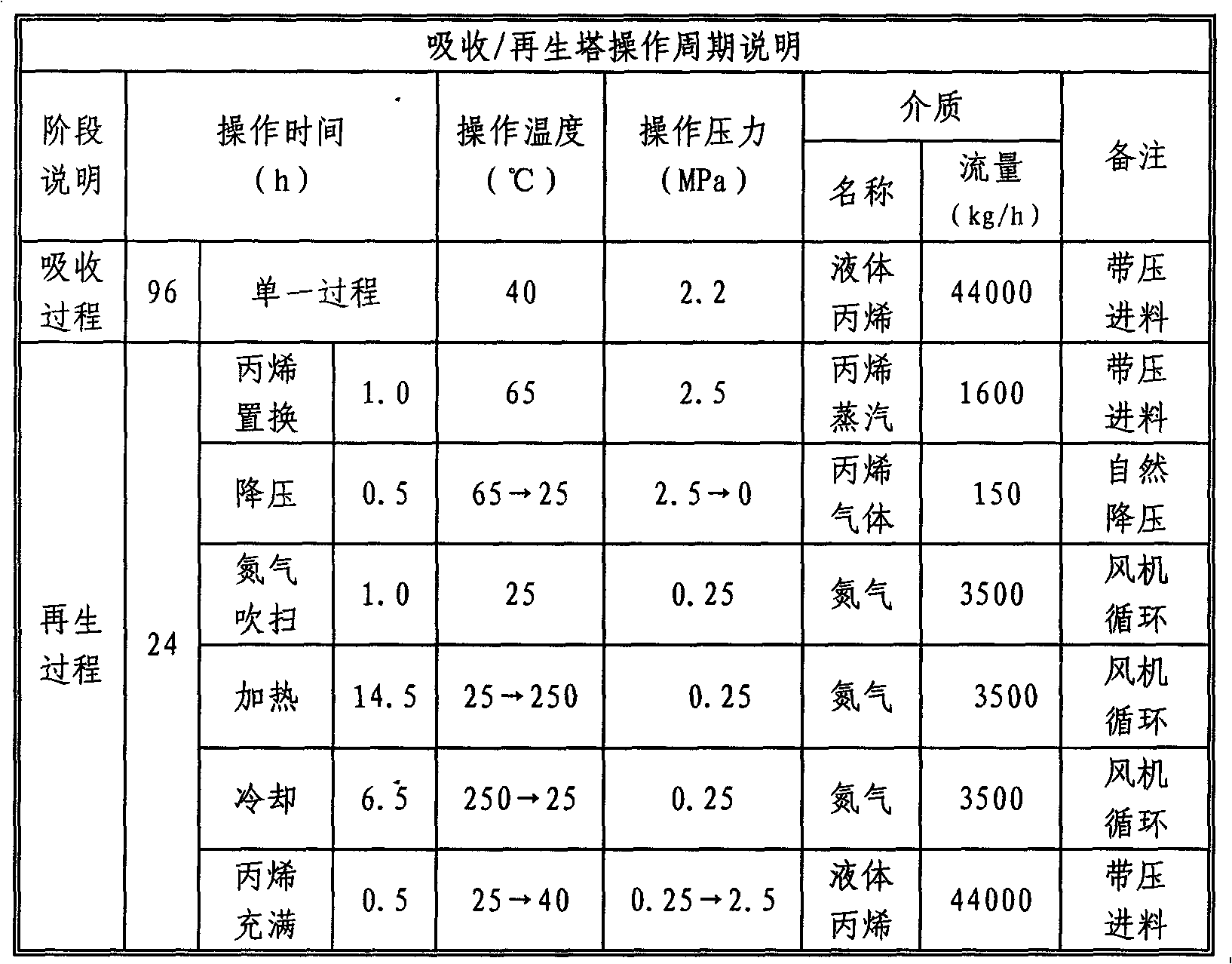

[0032] (1) Propylene dehydration consists of absorption process and regeneration process.

[0033] Absorption process function:

[0034] The first adsorption / regeneration tower 1 (or the second adsorption / regeneration tower 2) is filled with molecular sieves. When the propylene liquid flows through the adsorption / regeneration tower 1 (adsorption / regeneration tower 2) vertically from bottom to top, the selective The characteristics of adsorption can absorb the water in the propylene liquid. After 120 hours of absorption, the molecular sieve can be regenerated by circulating hot nitrogen after the absorption is completely saturated, so that the molecular sieve can be recycled.

[0035] Regeneration process function:

[0036] Use circulating hot nitrogen to remove the moisture in the saturated molecular sieve in the first adsorption / regeneration tower 1 (or the second ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com