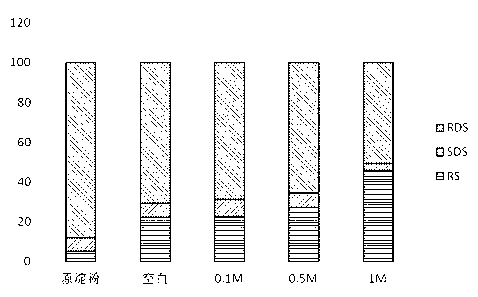

Method for preparing resistant starch by adopting acid and heat treatment

A technology of resistant starch and acid heat treatment, which is applied in the field of starch industry and achieves the effects of simple preparation process, strong application prospect and reduced digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add 20g of cornstarch into 30mL of 0.01mol / L citric acid solution, mix well, put it in an oil bath at 140°C and heat for 10min, and keep stirring continuously. After heating, it was cooled to room temperature in air, and then placed in a refrigerator at 4°C for 24 hours. Take out the refrigerated sample and dry it in an oven at 35°C for 48 hours, then grind it through a 100-mesh sieve to obtain starch powder, wash the powder with deionized water 5 times, discard the supernatant, and dry the precipitate at 35°C for 24 hours , and finally crushed through a 100-mesh sieve to obtain a resistant starch sample.

Embodiment 2

[0018] Add 20g of cornstarch into 30mL of 0.05mol / L citric acid solution, mix well, put it in an oil bath at 140°C and heat for 20min, and keep stirring continuously. After heating, it was cooled to room temperature in air, and then placed in a refrigerator at 4°C for 48 hours. Take out the refrigerated sample and dry it in an oven at 35°C for 48 hours, then grind it through a 100-mesh sieve to obtain starch powder, wash the powder with deionized water 5 times, discard the supernatant, and dry the precipitate at 35°C for 24 hours , and finally crushed through a 100-mesh sieve to obtain a resistant starch sample.

Embodiment 3

[0020] Add 20g of cornstarch into 30mL of 0.1mol / L citric acid solution, mix well, put it in an oil bath at 140°C and heat for 30min, and keep stirring continuously. After heating, it was cooled to room temperature in the air, and then placed in a refrigerator at 4°C for 72 hours. Take out the refrigerated sample and dry it in an oven at 35°C for 48 hours, then grind it through a 100-mesh sieve to obtain starch powder, wash the powder with deionized water 5 times, discard the supernatant, and dry the precipitate at 35°C for 24 hours , and finally crushed through a 100-mesh sieve to obtain a resistant starch sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com