Composite highland flour rich in slow-digesting starch and preparation method thereof

A technology of slow-digesting starch and highland barley powder, applied in the field of compound highland barley powder rich in slow-digesting starch and its preparation, to achieve the effects of maintaining blood sugar steady state, continuously releasing energy, and slowly absorbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

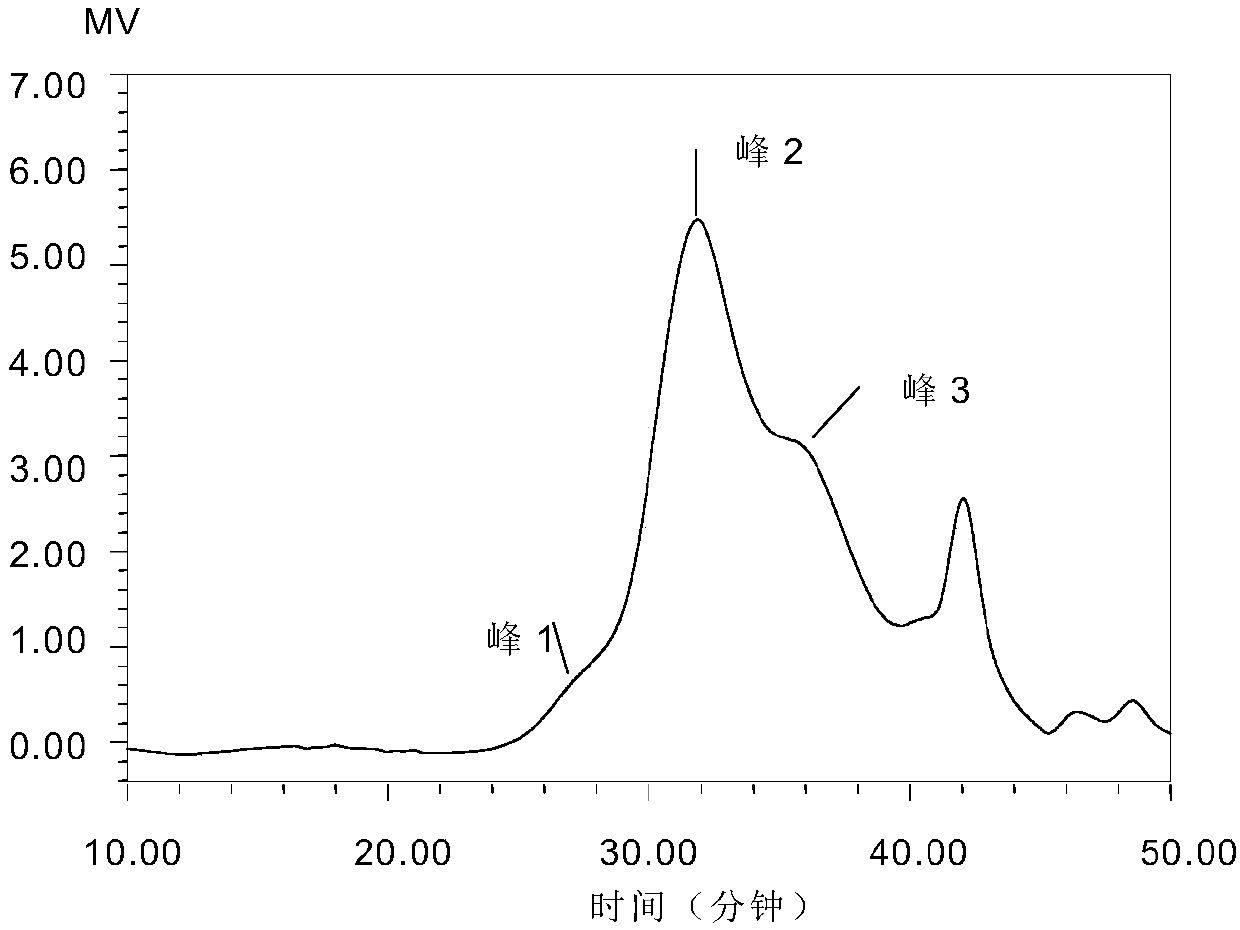

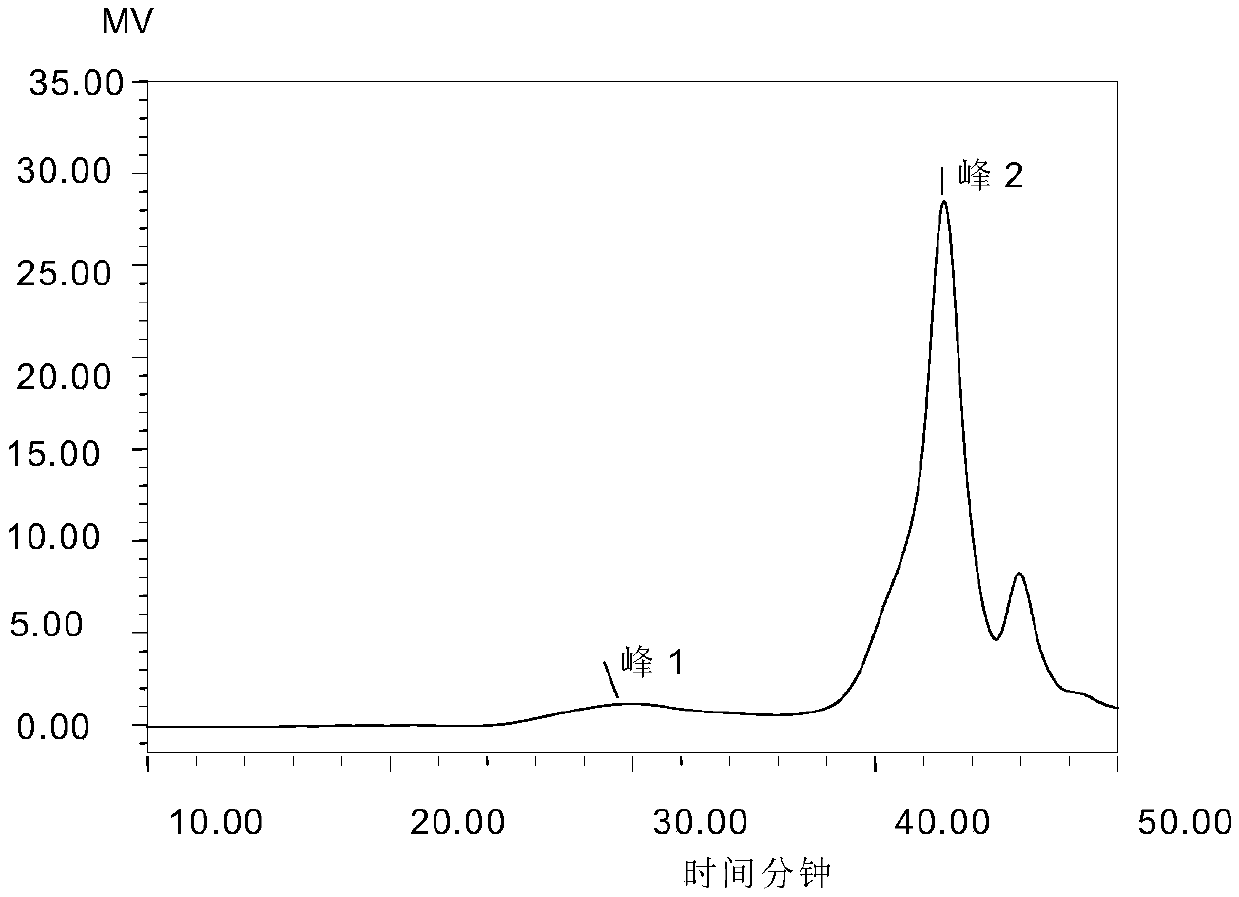

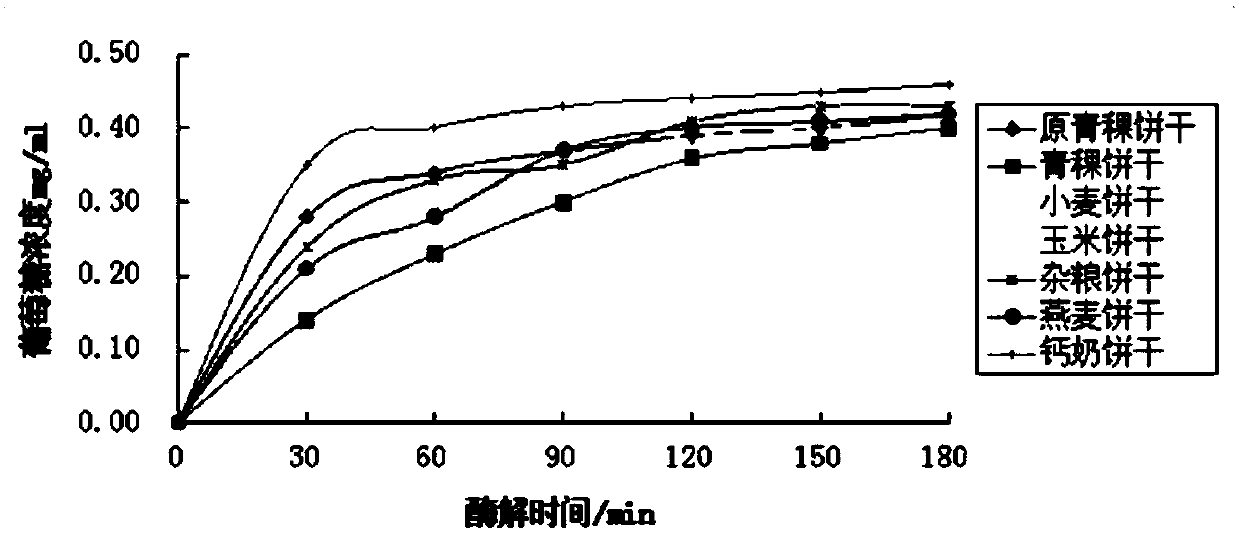

Method used

Image

Examples

Embodiment 1

[0042] To make highland barley powder milk with a raw material mass concentration of 5%, crush fresh brown mushroom bisporus fruit bodies into a slurry and homogenize, add the brown mushroom bisporus slurry to the highland barley powder milk, and heat at 90°C to form brown bisporus Mushroom and highland barley flour paste; wherein, the brown mushroom bisporus slurry accounts for 5% of the total volume of the mixture.

[0043] After cooling, add 0.5mol / L sodium acetate buffer solution to adjust the pH value to 5.0.

[0044]Enzymolyze the cooled brown Agaricus bisporus and highland barley flour paste at 40°C. The enzymes used for enzymolysis include 25U / L of α-maltose amylase and 10U / L of transglucosidase. Boiling water bath The enzymatic hydrolysis product was obtained after the enzyme was inactivated. The enzymatic hydrolysis time was 1 hour, and the enzyme was inactivated in a boiling water bath for 5 minutes.

[0045] Then cool the starch milk and add 2 times the volume of ...

Embodiment 2

[0049] To make highland barley powder milk with a raw material mass concentration of 35%, crush fresh brown mushroom bisporus fruiting body into a slurry and homogenize it, add the brown mushroom bisporus slurry to the highland barley powder milk, heat at 95°C to form brown bisporus Mushroom and highland barley flour paste; wherein, the brown mushroom bisporus paste accounts for 25% of the total volume of the mixture.

[0050] After cooling, add 0.5mol / L sodium acetate buffer to adjust the pH value to 6.0; enzymolyze the cooled brown Agaricus bisporus and barley powder paste at 60°C, and the enzymes used for enzymolysis include the amount of α-maltose amylase added The amount of transglucosidase was 90U / L, and the amount of transglucosidase added was 45U / L. The enzymolysis product was obtained after the enzyme was inactivated in a boiling water bath. The enzymatic hydrolysis time was 5 hours, and the enzyme was inactivated in a boiling water bath for 5 minutes.

[0051] Then, ...

Embodiment 3

[0054] To make highland barley powder milk with a raw material concentration of 20%, crush fresh brown Agaricus bisporus fruit bodies into a slurry and homogenize, add the brown mushroom bisporus slurry to the highland barley powder milk, and heat at 93°C to form brown bisporus Mushroom and highland barley flour paste; wherein, the brown mushroom bisporus slurry accounts for 15% of the total volume of the mixture.

[0055] After cooling, add 0.5mol / L sodium acetate buffer to adjust the pH value to 5.5; enzymolyze the cooled brown Agaricus bisporus and highland barley flour paste at 50°C, and the enzymes used for enzymolysis include the amount of α-maltose amylase added The amount of transglucosidase was 75U / L, the amount of transglucosidase added was 35U / L, and the enzymatic hydrolysis product was obtained after the enzyme was inactivated in a boiling water bath. The enzymatic hydrolysis time was 3 hours, and the enzyme was inactivated in a boiling water bath for 5 minutes.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com