High-energy composite repair method for shallow cracks of titanium alloy

A composite repair and titanium alloy technology, applied in the field of surface repair, can solve problems such as the adverse effect of alloy fatigue properties, and achieve the effect of improving fatigue resistance and fatigue strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

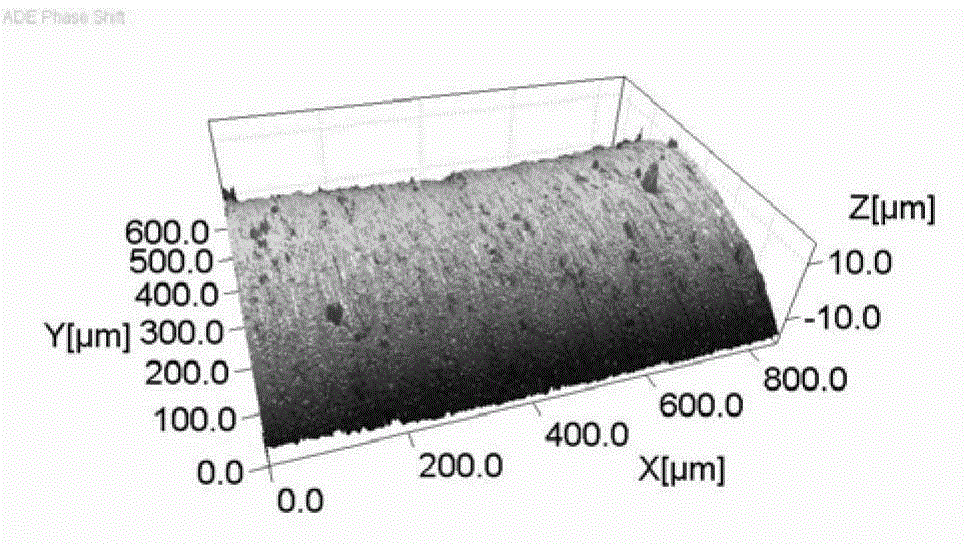

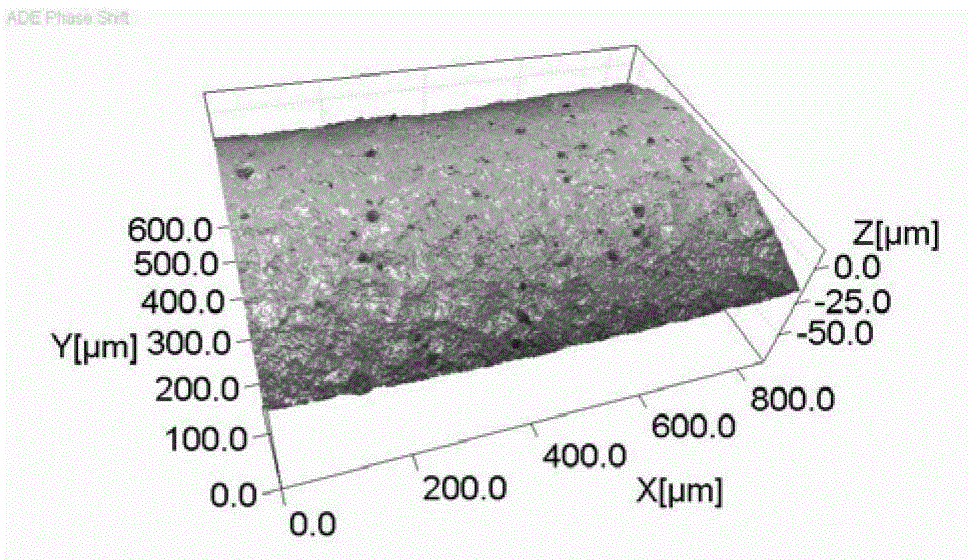

[0008] Using shot peening and high-energy pulsed electron beam modification treatment to repair and repair the shallow cracks of titanium alloy parts, it is used to improve the surface performance of the material and ensure the reliability of the parts. This technology has the following technical characteristics.

[0009] (1) Number of pulses: 5 to 30 times;

[0010] (2) The duration of a single pulse: 50μs~200μs;

[0011] (3) Pulse energy: 10J / cm 2 ~30J / cm 2 ;

[0012] (4) Nano structure depth: 0μm~15μm;

[0013] (5) Nano structure size: less than 100nm;

[0014] (6) Shot peening strength: 0.05A~0.25A;

[0015] (7) Shot peening surface coverage: 100%~300%;

[0016] (8) Usable shots: ceramic shots, cast steel shots and glass shots.

[0017] Specific steps are as follows:

[0018] 1. Use pulsed electron beam equipment to process titanium alloy materials.

[0019] 1 boot

[0020] Start the device and load high voltage.

[0021] 2 artifacts

[0022] 2.1 Processing inspection: Check the surface qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com