Structure and construction method of muddy coast sheet pile wharf

A sheet pile wharf and construction method technology, which is applied in the field of coastal wharfs, can solve the problems of blind sheet piles not being able to function as a curtain, large bending moments of the front wall of the blind sheet pile and sheet pile, and low shear strength of silt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

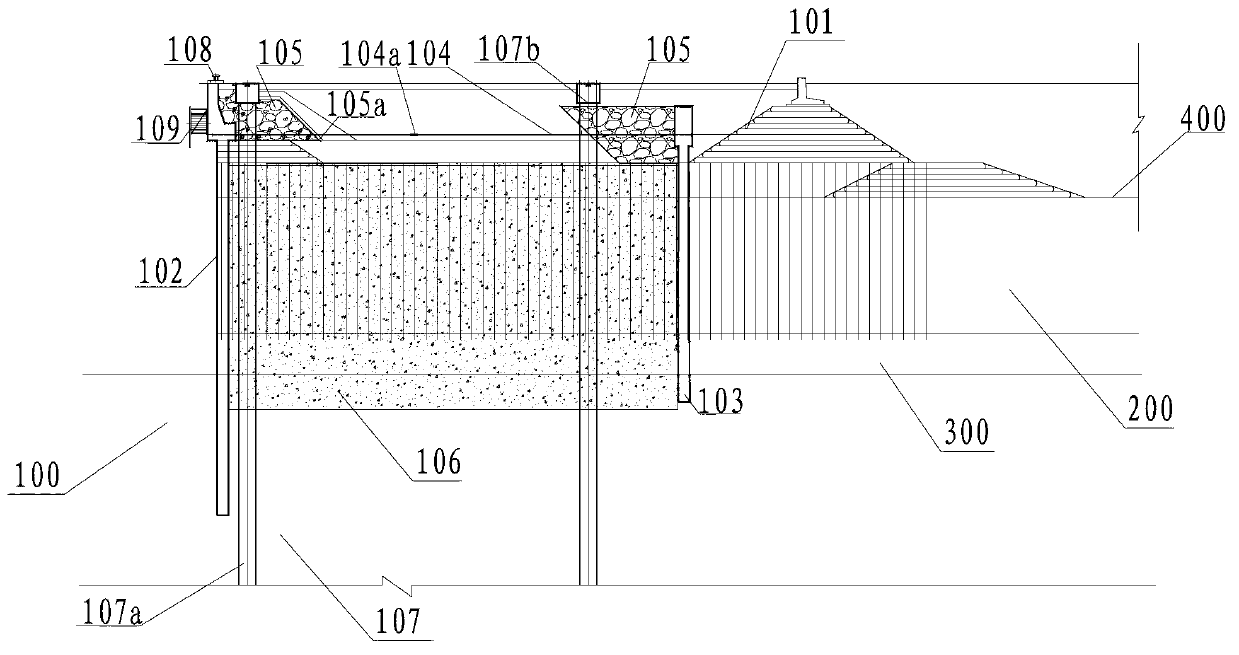

[0039] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

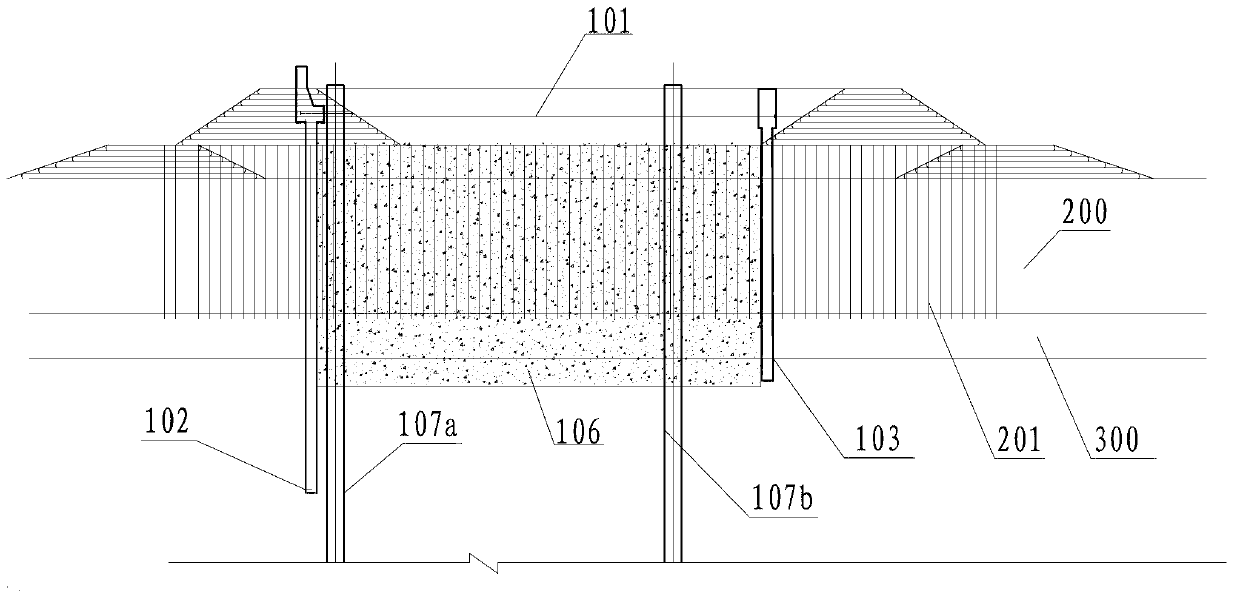

[0040] see image 3 , which shows a structural example of the sheet piling wharf suitable for muddy coast provided by the present invention. It can be seen from the figure that the entire sheet pile wharf 100 is mainly composed of a temporary embankment 101, a front sheet pile wall 102, a rear anchorage wall 103, an anchorage rod 104, a riprap prism 105, a cement mixing pile 106, and a track pile foundation 107. become.

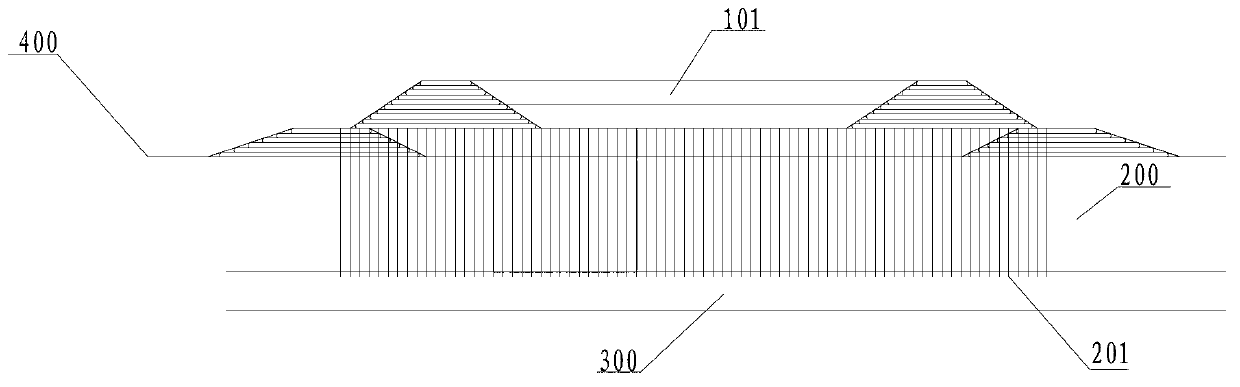

[0041] see figure 1 , the temporary embankment 101 is set on the silt foundation 200 to provide conditions for the subsequent onshore construction of the sheet pile structure. Since the silt foundation has no land construction conditions, it is necessary to build a temporary embankment to provide it. In the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com