Assembled supporting-free prefabricated light composite floor slab with ribs

A technology for laminating floor slabs and prefabricated slabs, applied in the direction of floor slabs, building components, buildings, etc., can solve the problems of wasting materials and cumbersome processes, and achieve the effects of reducing wet work, good effect and improving construction accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

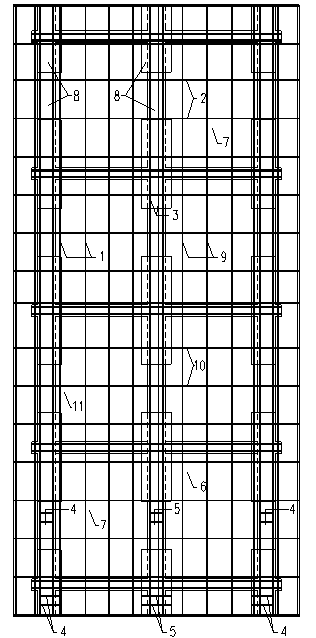

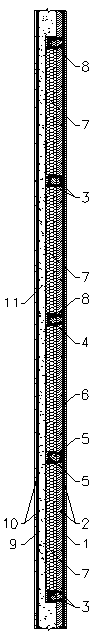

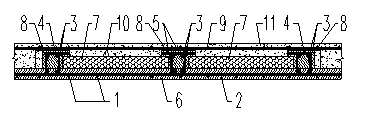

[0023] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

[0024] Assembled support-free prefabricated ribbed lightweight (prestressed) laminated slab is a new type of floor slab that first processes the lower components of the slab in the factory, and then binds the upper reinforcement of the slab and pours the upper concrete of the slab at the construction site to form an integral slab. Prefabricated composite floor form. Since the polystyrene board (or other lightweight building materials) is used as a substitute for most of the concrete that does not contribute to the overall floor force, the self-weight and reinforcement of the floor are greatly reduced, and the one-way or two-way slab ribs are effectively improved. In addition to the rigidity of the laminated slab, it also solves the problem of shear resistance of the new and old concrete laminated surfaces; this technology can also use prestre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com