Novel mesh-added light building block

A block, a new type of technology, applied in the direction of building materials, etc., can solve the problems of complicated and simple manufacturing process, and the manufacturing method has not really been achieved, and achieve the effect of low thermal conductivity, simple manufacturing, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

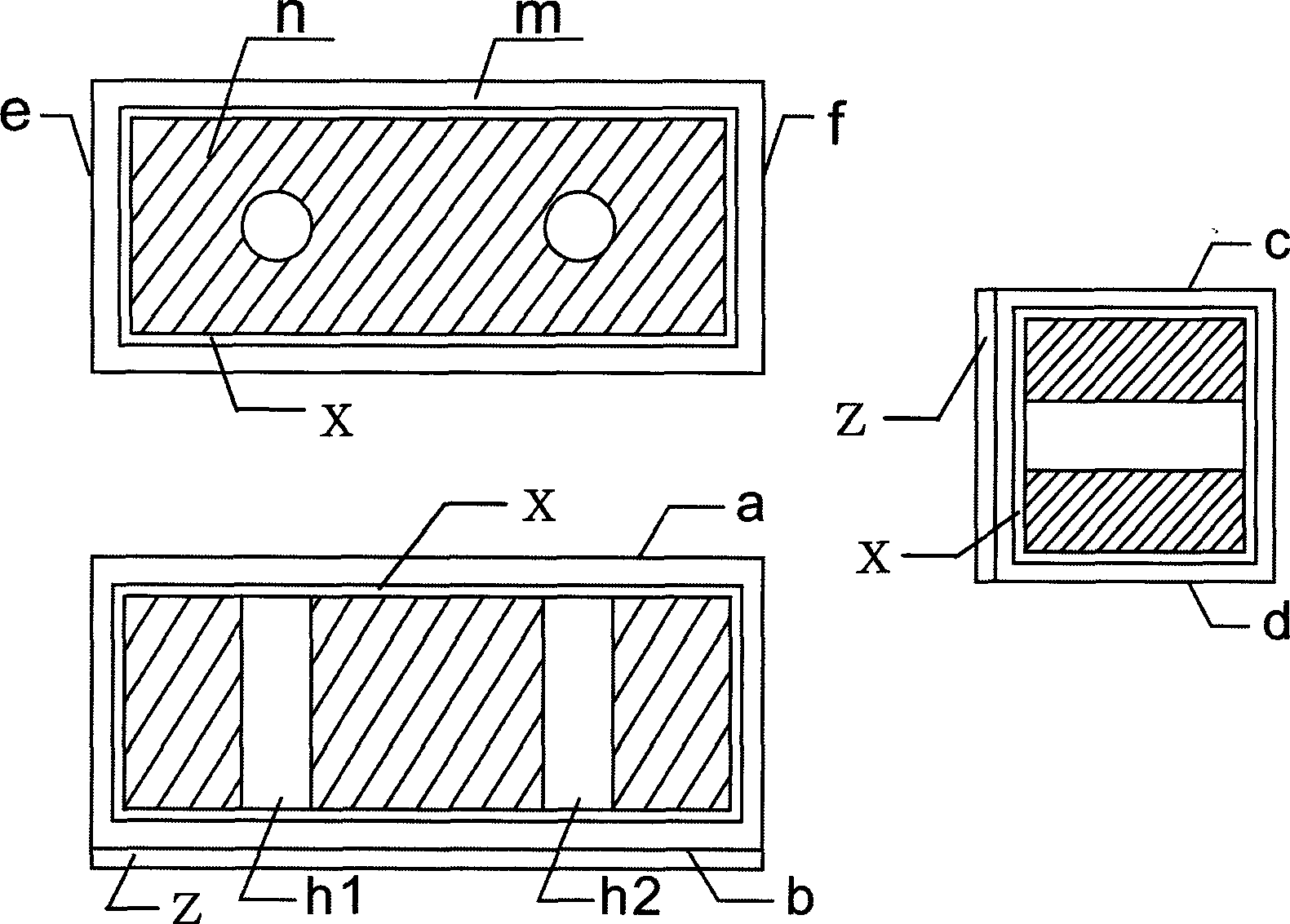

[0010] like figure 1 The block of the present invention shown is to meet the relevant requirements of building material application standards and cement products. The adhesive and load-bearing skeleton used in the block are ordinary Portland concrete m, and the wall thickness of the concrete m is related to the load-bearing capacity of the block. There is an important relationship between pressure bearing requirements, therefore, after many experiments and trial verifications, it is concluded that the lightweight building blocks that meet the requirements of the standard have a wall thickness of figure 1 Shown: side a and side b are 3CM, and the other four sides of cdef are 2cm.

[0011] like figure 1 The block of the present invention shown is to meet the relevant requirements of building material application standards and cement products. The adhesive and load-bearing skeleton used in the block are ordinary Portland concrete m, and the wall thickness of the concrete m is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com