Production method for convenient assembled door

A manufacturing method and a convenient technology, applied in the direction of door leaves, windows/doors, window/door frames, etc., can solve the problems of inflexible customization methods, long processing time of the whole door, complicated manufacturing process, etc., to improve initiative and flexibility Sexuality, prolonging the production and processing time, and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

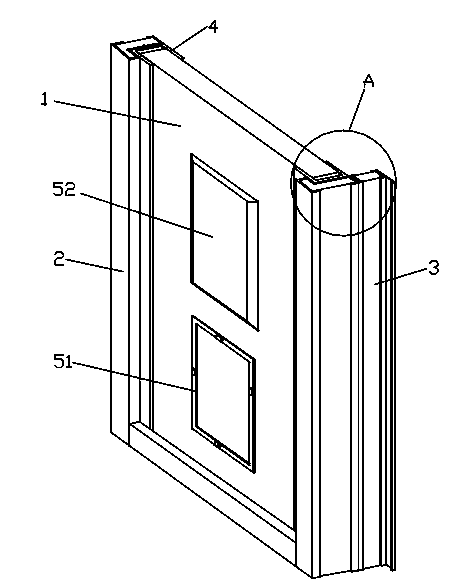

[0042] As shown in the accompanying drawings, a method for making a conveniently assembled door is characterized in that it includes the following manufacturing steps:

[0043] A. Separately process the door panel standard parts, door frame standard parts and door cover standard parts of fireproof and anti-theft doors;

[0044] B, the surface of the exposed standard part is painted in the standard part made by step A;

[0045] C, cutting and assembling the standard parts made by steps A and B to make door panel 1, door frame 2 and door pocket 3;

[0046] D. Assemble and install the cut and assembled door panels, door frames and door pockets on the wall.

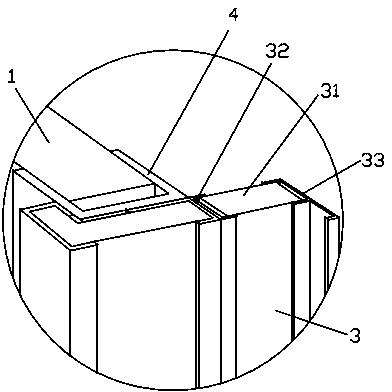

[0047] Wherein the standard door panel includes a door panel 1 and an integrally formed door panel frame 4 for being arranged on the side end surface of the door panel 1; the door panel frame 4 is provided with a card slot 41 adapted to the thickness of the door panel 1; when assembling, the door panel 1 is inserted into the...

Embodiment 2

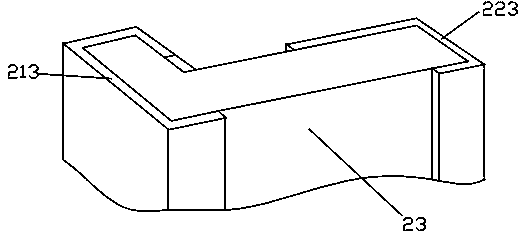

[0054] The difference from the above-mentioned embodiment is that step A also includes making a decorative male corner standard part, and the decorative male corner standard part includes a connecting frame 51 for being arranged on the outer surface of the door panel and a male corner decoration for being arranged on the connecting frame 51 Panel 52. Therefore, the manufacturing step also includes step E, that is, fixing the connecting frame 51 on the outer surface of the door panel 1 with glue or bolts, and then fastening the male corner decorative panel 52 to the connecting frame 51 . The decorative positive corners have a strong three-dimensional sense, are beautiful and easy to install. The decorative pattern can be temporarily selected without being affected by the construction period or process of the assembled door. The flexibility is high, the processing is convenient, and the installation is simple, which makes the assembled door more convenient and more beautiful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com