System for resisting polarization fading of natural gas pipe leakage detecting sensor group

A technology of natural gas pipelines and sensor groups, applied in the field of anti-polarization fading systems, can solve problems such as low sensitivity, high false alarm rate, and easy to be affected by environmental factors, and achieve the effect of improving sensing sensitivity and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

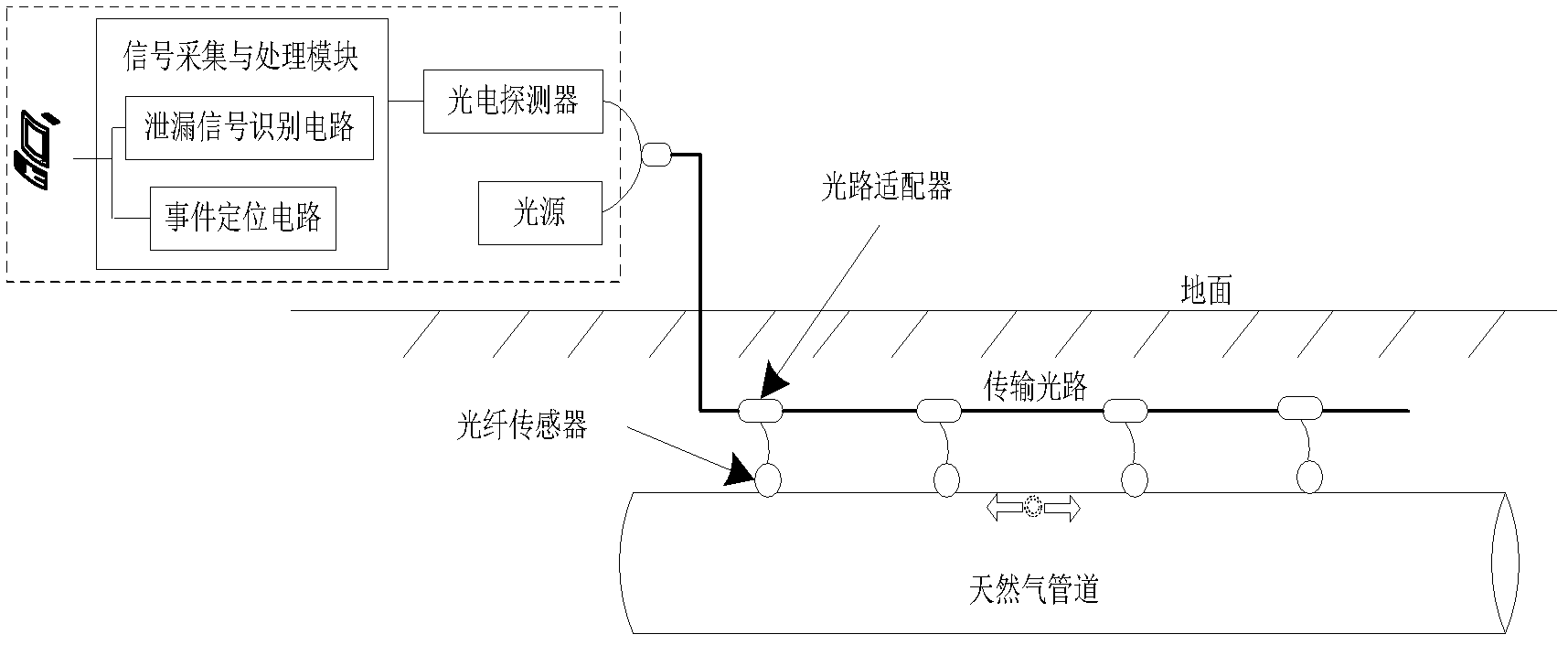

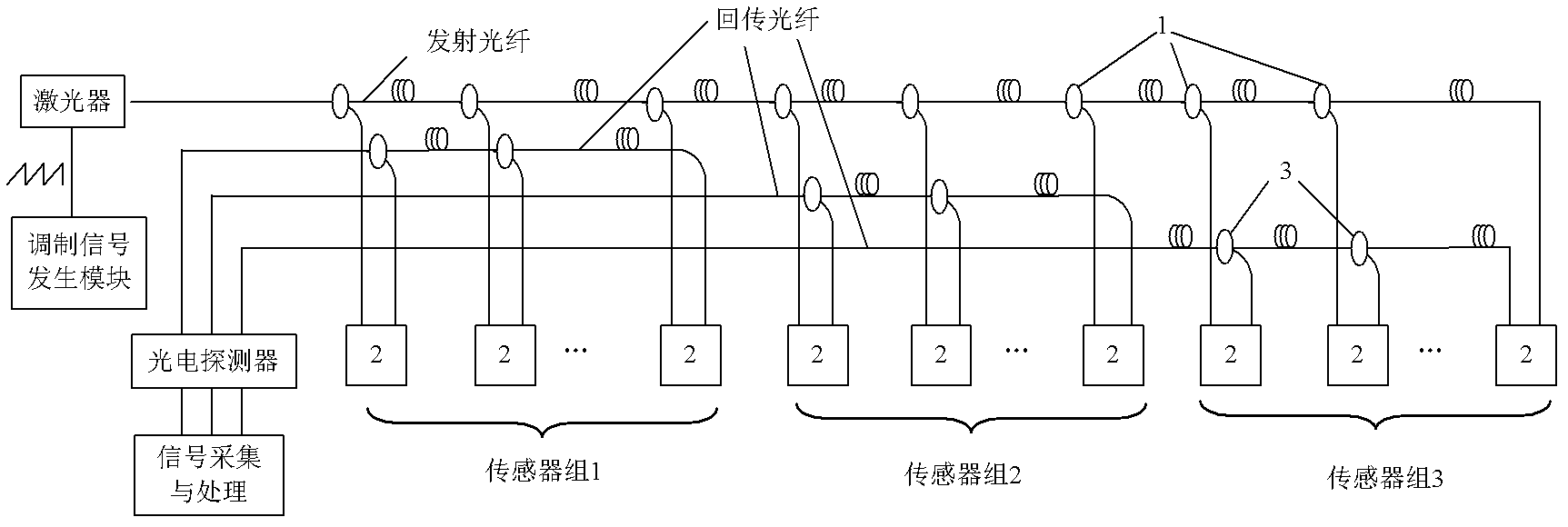

[0057] Embodiment. The composition of this example is as figure 1 and figure 2 As shown, it includes a light source, an optical system and a circuit part; a fiber optic sensor is installed on the pipeline body every 1.5km, and a total of 10 sensors are installed. The first 5 sensors and the last 5 sensors form a sensor group respectively, and each fiber optic sensor The group shares a launch fiber to connect with the light source, and each fiber sensor group uses a return fiber to connect to the photodetector; the output of the photodetector is connected to a signal acquisition and processing module including leakage signal identification and event location functions, and the signal The acquisition and processing module includes a signal conditioning unit, a signal acquisition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com