Water-cooled type low-temperature refrigerant compressor unit with economizer and silencer

A technology of compressor units and economizers, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of compressors with high noise, general efficiency, pipeline vibration, etc., to reduce noise and vibration, and improve safety performance and energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

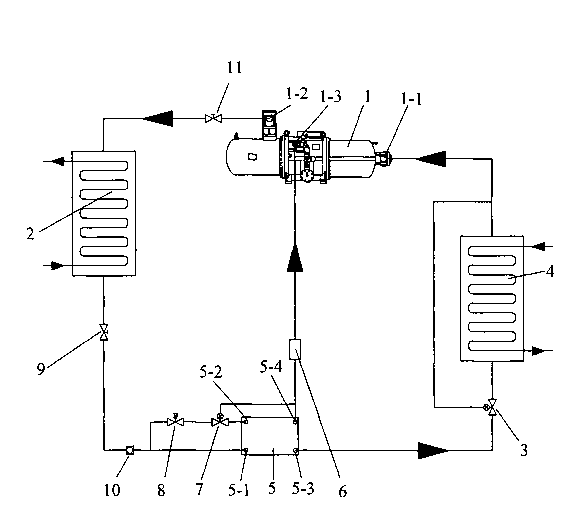

[0023] Such as figure 1 As shown, a water-cooled low-temperature refrigeration compressor unit with an economizer and a silencer includes: a compressor 1, a condenser 2, an expansion valve A3 including a temperature sensing bulb, and an evaporator 4.

[0024] The compressor 1 is a medium-temperature screw compressor including a suction inlet 1-1, an exhaust outlet 1-2 and an economizer connection spare port 1-3.

[0025] The exhaust outlet 1-2 is sequentially connected to the condenser 2, the expansion valve A3, the evaporator 4 and the suction inlet 1-1, and the temperature sensing bulb of the expansion valve A3 is connected between the evaporator 4 and the suction inlet 1-1.

[0026] An economizer 5, a muffler 6, an expansion valve B7 including a temperature-sensing bulb, and a solenoid valve 8 are also provided between the condenser 2, the expansion valve A3, and the economizer connection backup port 1-3. The economizer 5 includes: a first inlet 5-1, a second inlet 5-2, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com