Reducing type communtator manufacturing method

A manufacturing method and variable diameter technology, which are applied in the field of motor parts and can solve problems such as milling and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The manufacturing method of the variable-diameter commutator provided by the present invention comprises the following steps in sequence ( Figure 10 is the process flow chart):

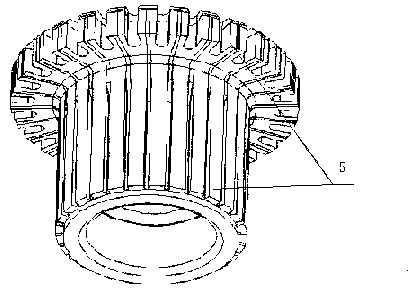

[0036] A. Manufacture a reduced-diameter copper case 1 with a central axis hole (see image 3 , Figure 4 , Figure 5 ), the variable-diameter copper shell 1 includes a circular ring 3 and a cylinder 2 fixedly connected to the circular ring 3, the outer diameter of the cylinder 2 is smaller than the outer diameter of the circular ring 3, and the circular A number of evenly distributed grooves 4 are formed on the ring 3 and the cylinder 2, and the grooves 4 divide the ring 3 and the cylinder 2 into a number of commutating segments 5 that are independent of each other. A connecting ring 10 is reserved on the outer wall of the commutating segment 5, and the connecting ring 10 connects all the commutating segments 5 as a whole, and the commutating segment 5 includes an upper section 11 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com