Laminated film and package

A technology for laminating films and packaging bodies, applied in packaging, wrapping paper, household packaging, etc., can solve the problems of intrusion into plastic containers, poor oxygen barrier properties, residual plastic containers, etc., and achieve the effect of excellent oxygen absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

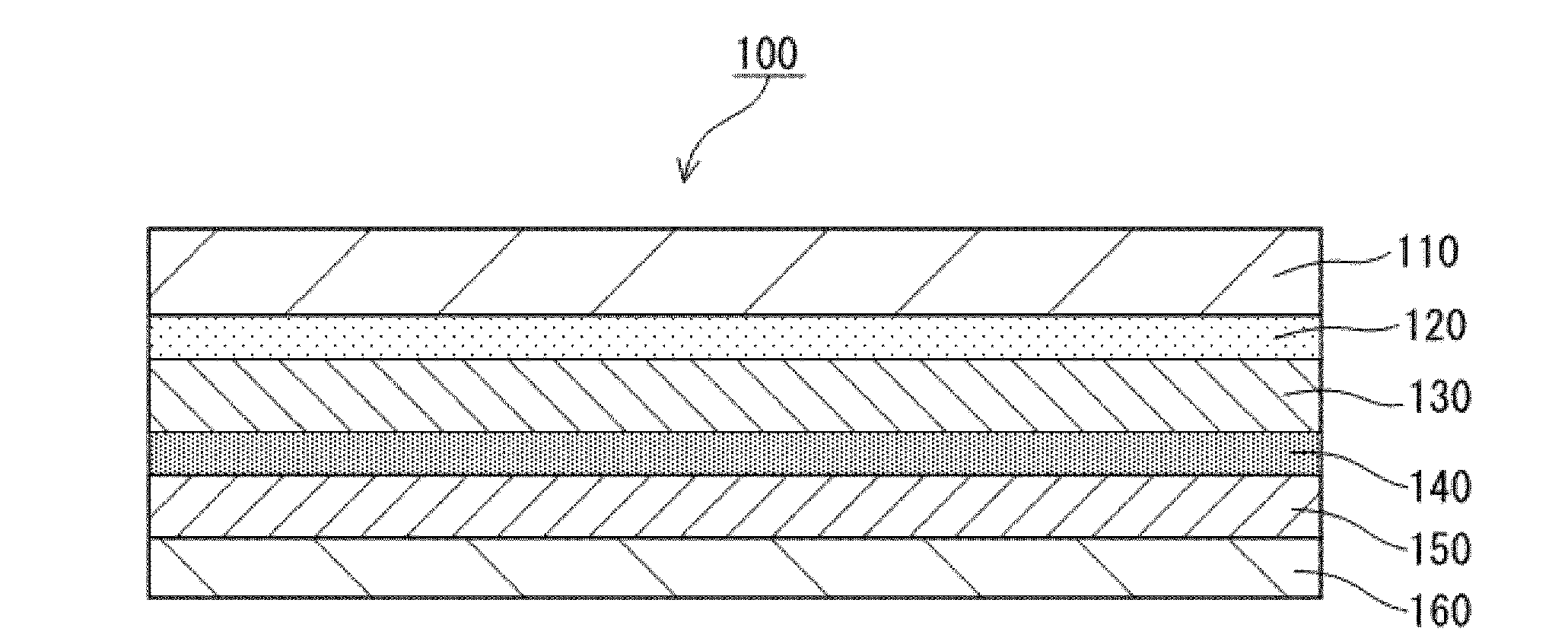

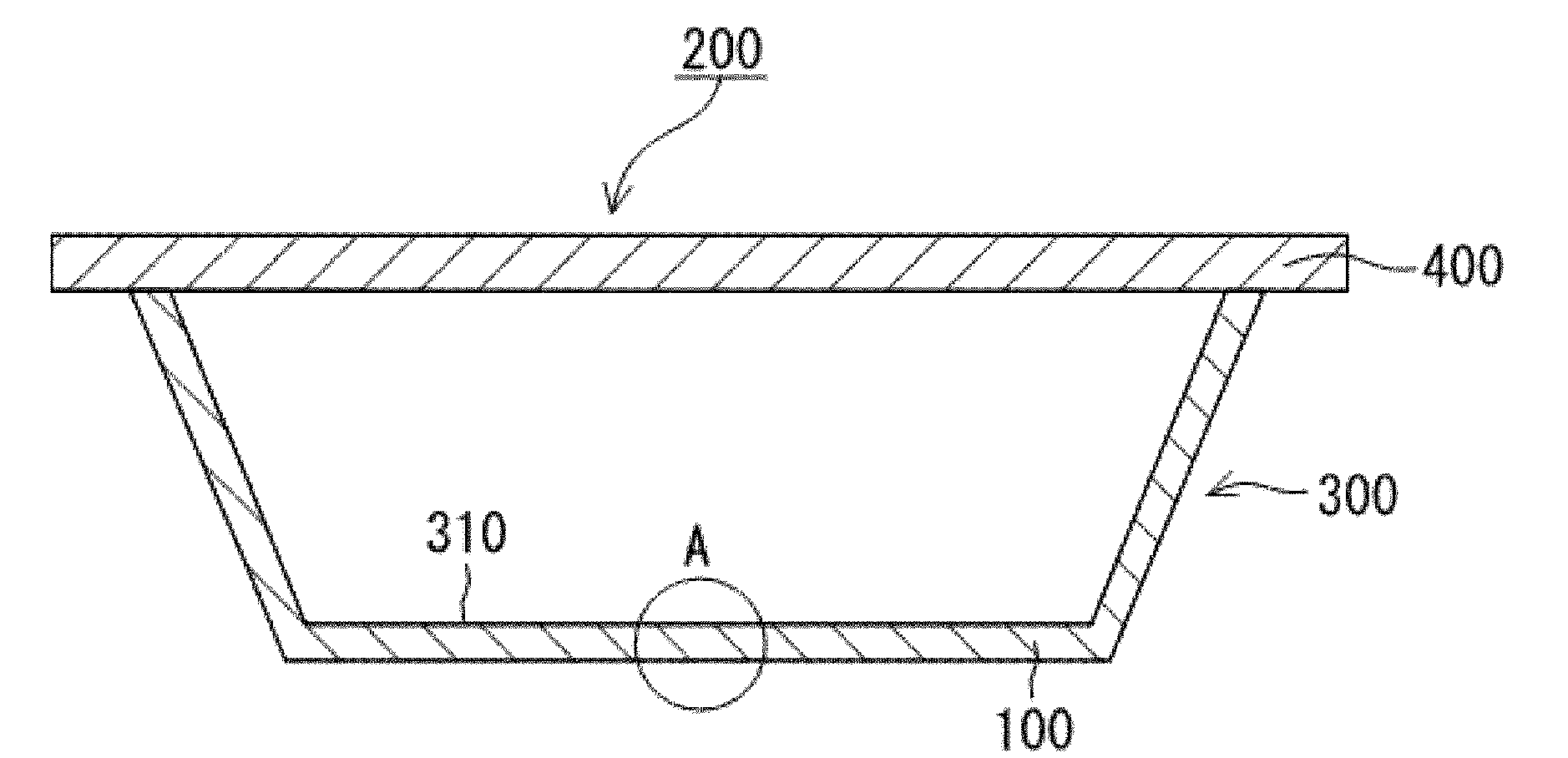

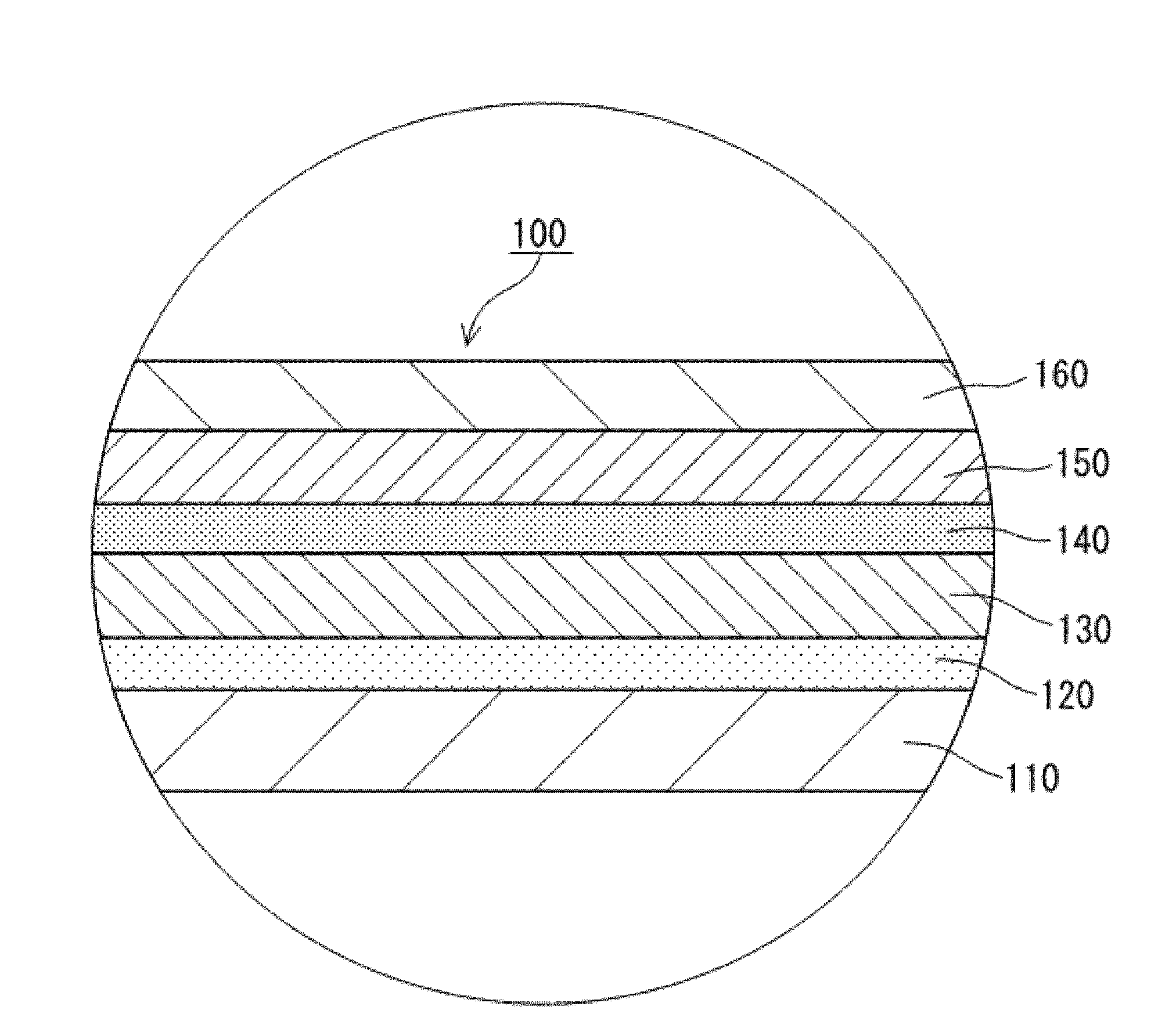

[0112]

[0113] Copolyester resin (manufactured by Eastman Chemical Japan Co., Ltd., model number: GN071) was prepared as the resin constituting the outer layer 110 . An adhesive polyolefin-based resin (manufactured by Mitsui Chemicals, Inc., model number: SF740) was prepared as the resin constituting the first adhesive layer 120 . As a resin constituting the barrier layer 130 , EVOH resin (manufactured by Kuraray Co., Ltd., model: J171B) was prepared. An adhesive polyolefin-based resin (manufactured by Mitsui Chemicals, Inc., model number: LF308) was prepared as the resin constituting the second adhesive layer 140 . A mixture of 80% by weight of the base resin and 20% by weight of the unsaturated polyolefin-based oxygen-absorbing resin was prepared as the resin constituting the oxygen-absorbing layer 150 . LDPE resin (manufactured by Ube Maruzen Polyethylene Co., Ltd., model: F522N) was prepared as the resin constituting the sealing layer 160 .

Embodiment 2)

[0125] A hindered phenolic antioxidant (manufactured by BASF, model number: IRGANOX1010) was added to the LDPE resin of the sealing layer 160 so that the content rate was 400 ppm by weight relative to the two layers (second adhesive layer 140 and sealing layer 160 ). , except that, the packaging body 200 was produced in the same manner as in Example 1, and the oxygen absorption amounts of the packaging body 200 on the first, third, and seventh days were measured in the same manner as in Example 1, respectively.

[0126] As a result, the oxygen absorption amount on the first day was 0.020cc / cm 2 , the oxygen absorption on the third day was 0.034cc / cm 2 , the oxygen absorption on the 7th day was 0.071cc / cm 2 (Refer to Table 1 below).

Embodiment 3)

[0128] A hindered phenolic resist is added to the adhesive polyolefin resin of the second adhesive layer 140 so that the content rate relative to the two layers (the second adhesive layer 140 and the sealing layer 160) is 400 ppm by weight. An oxidizing agent (manufactured by BASF, model number: IRGANOX1010) was used to prepare a package 200 in the same manner as in Example 1, and to measure the oxygen absorption of the package 200 on the first, third, and seventh days in the same manner as in Example 1.

[0129] As a result, the oxygen absorption amount on the first day was 0.019cc / cm 2 , the oxygen absorption on the third day was 0.036cc / cm 2 , the oxygen absorption on the 7th day was 0.067cc / cm 2 (Refer to Table 1 below).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com