Resin composition, and multilayer structure and packaging material using same

A technology of resin composition and copolymer, which is applied in household packaging, bio-packaging, transportation and packaging, etc. It can solve the problems of cooking shock, oxygen barrier reduction, and the quality reduction of the contents of the container, so as to suppress unpleasant odor, oxygen Excellent absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

[0169] (Example 1: Production of oxygen-absorbing film and multilayer structure)

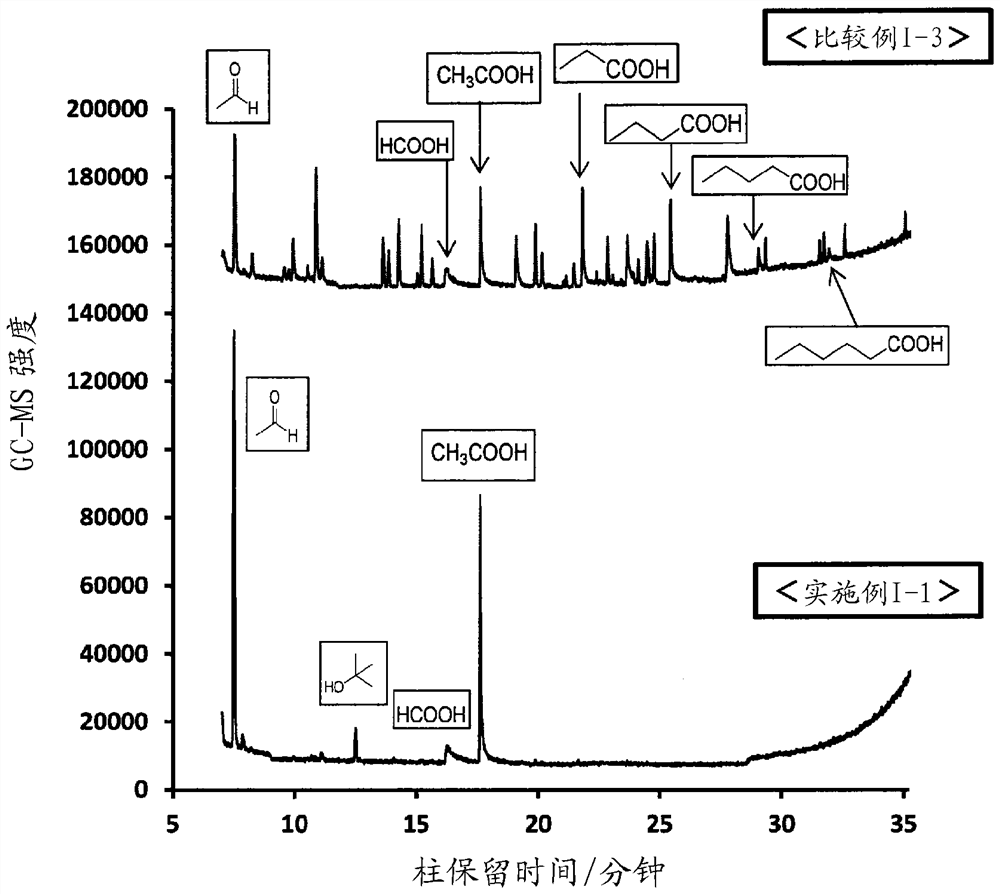

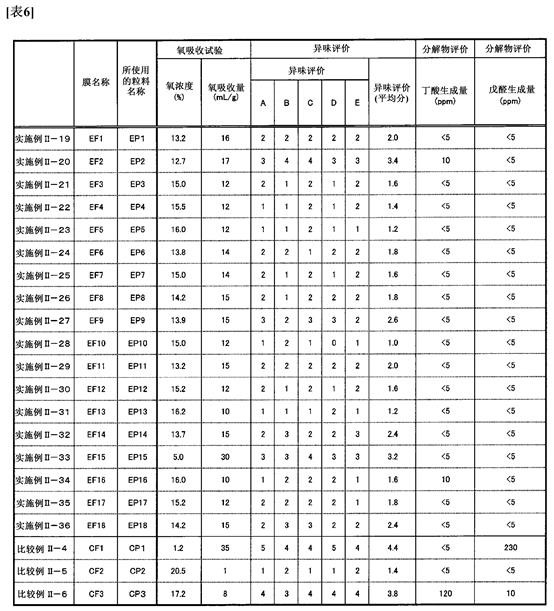

[0170] (I-a) Evaluation of oxygen absorption

[0171] Cut out 100 mg of the oxygen-absorbing films obtained in Examples I-1 to I-24 and Comparative Examples I-1 to I-5 as samples, put them in a pressure-resistant glass bottle with an inner volume of 35.5 mL under air, and use The aluminum lid with Naflon-rubber gasket was sealed and stored at 40°C and 22%RH for 14 days. The oxygen concentration in the container after storage was measured using Pack Master (manufactured by Iijima Denshi Kogyo Co., Ltd.).

[0172] (I-b) Evaluation of odor after oxygen absorption

[0173] The samples prepared and stored in the same manner as in (I-a) above were opened, and the odor in the container was judged by 5 professionals according to the following criteria, and the average score of the judgment results obtained was calculated. A lower score indicates less off-odor.

[0174] 5: A strong unpleasant odor like...

Embodiment I-1

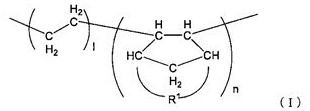

[0184] (Example I-1: Production of an oxygen-absorbing film)

[0185] 100 mass of EPDM elastomer ("NORDEL IP4770P" manufactured by Dow Chemical Co., Ltd., Mw=200,000, MFR=0.07g / 10min) composed of monomers of ethylene, propylene, and 5-ethylidene-2-norbornene 0.4 parts by mass of manganese stearate as a transition metal catalyst (B) was mixed in each part, and a twin-screw kneading extruder (screw diameter: 25mmφ, L / D=30, manufactured by Toyo Seiki Seisakusho Co., Ltd.) was used. After melting and kneading at a barrel temperature of 230°C and a screw speed of 50 revolutions per minute, extrude from the mold in the form of strands into a cooling water tank at 5°C, and use a strand cutter to granulate. Thus pellets are obtained.

[0186] Next, the pellets were put into a single-layer extruder (screw diameter: 20mmφ, L / D=20, manufactured by Toyo Seiki Seisakusho Co., Ltd.), and the temperature of the barrel was 230°C, and the screw speed was 40 per minute. Melt-kneading was carr...

Embodiment I-2~I-6

[0188] (Examples I-2 to I-6: Production of oxygen-absorbing membranes)

[0189] Except that the ethylene-cyclic olefin copolymer (A) was changed to the EDPM elastomer composed of the monomer units described in Table 1, an oxygen-absorbing film was produced in the same manner as in Example I-1, and various Evaluation. The compositions of the oxygen-absorbing films are shown in Tables 1 and 2, and the results of evaluations (I-a) and (I-b) are shown in Table 3.

[0190] It should be noted that each EDPM elastomer recorded in the category column in Table 1 corresponds to the following products:

[0191] "NORDEL IP3745P" (manufactured by Dow Chemical Co., Ltd., Mw=140,000, MFR=0.2g / 10min)

[0192] "NORDEL IP4820P" (manufactured by Dow Chemical Co., Ltd., Mw=75,000, MFR=1g / 10min)

[0193] "Mitsui EPT K-9720" (manufactured by Mitsui Chemicals, Mw=60,000, MFR=2g / 10min)

[0194] "Mitsui EPT X-3012P" (manufactured by Mitsui Chemicals, MFR=5g / 10min)

[0195] "RoyalEdge5041" (manufa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com