Multilayer-structured molded article

A technology of multi-layer structure and formed body, which is applied in the direction of layered products, synthetic resin layered products, packaged food, etc., can solve the problem of uneven thickness of the middle layer, achieve the elimination of uneven thickness, alleviate the drop of melt viscosity, prevent The effect of uneven thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

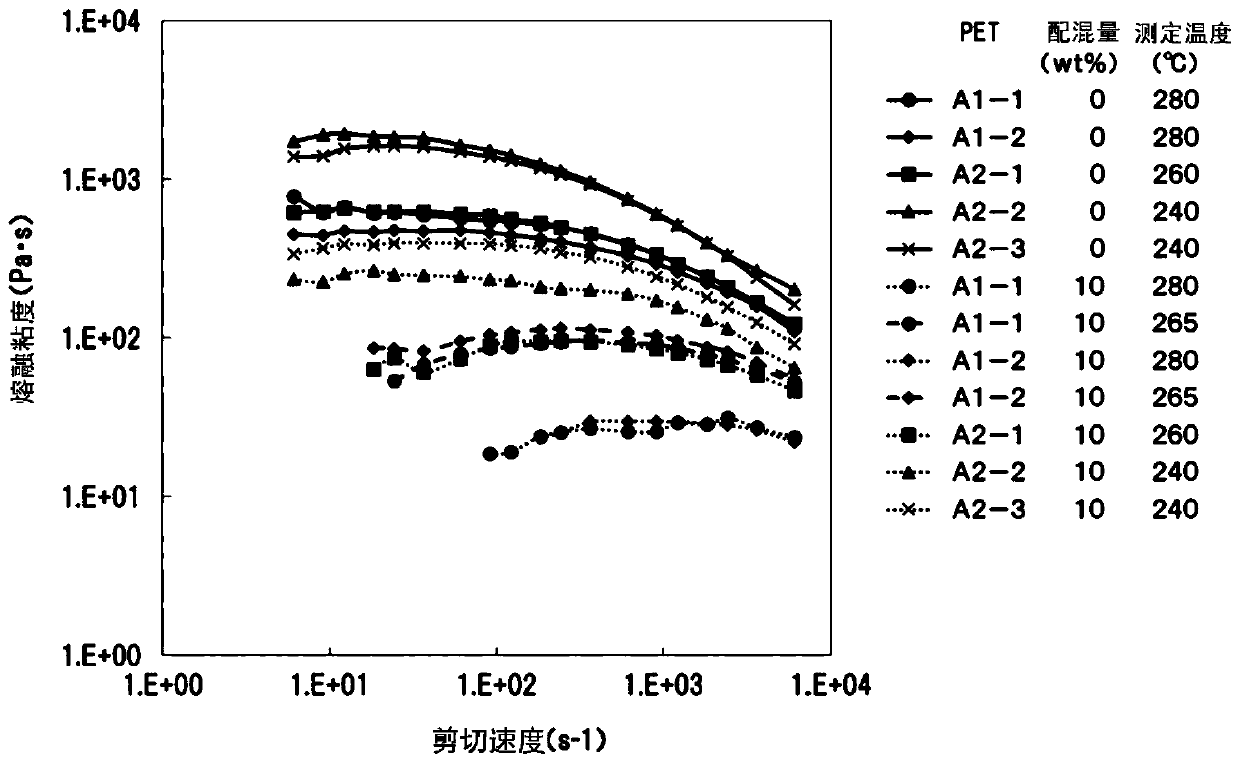

[0218] The oxygen-absorbing resin pellets using the second ethylene terephthalate-based polyester resin (A2-1) were charged into a hopper of an injection machine for forming an intermediate layer. When the forming temperature of the intermediate layer was 260° C., a multilayer preform was formed by the method described above, thereby forming a multilayer blow molded bottle.

[0219] Table 1 shows the composition of the formed bottle, the forming temperature of the intermediate layer, the formability, the haze of the main body portion of the preform, and the haze of the main body portion of the bottle.

Embodiment 2

[0221] Except that the oxygen-absorbing resin pellets using the second ethylene terephthalate-based polyester resin (A2-2) were put into the hopper of the injection machine for forming the intermediate layer and the molding temperature of the intermediate layer was 240° C. Multilayer blow molded bottles were formed and measured in the same manner as in Example 1.

[0222] Table 1 shows the composition of the formed bottle, the forming temperature of the intermediate layer, the formability, the haze of the main body portion of the preform, and the haze of the main body portion of the bottle.

Embodiment 3

[0224] Except that the oxygen-absorbing resin pellets using the second ethylene terephthalate-based polyester resin (A2-3) were charged into the hopper of the injection machine for forming the intermediate layer and the molding temperature of the intermediate layer was 240° C. Multilayer blow molded bottles were formed and measured in the same manner as in Example 1.

[0225] Table 1 shows the composition of the formed bottle, the forming temperature of the intermediate layer, the formability, the haze of the main body portion of the preform, and the haze of the main body portion of the bottle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com