Sterilization process method for bottle-planted needle mushroom factory production

A process method, the technology of Flammulina velutipes, applied in botany equipment and methods, horticulture, application, etc., can solve the problems of high production cost, high enterprise pressure, low yield rate, etc., and achieve improved product yield rate, simple process method, and equipment The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

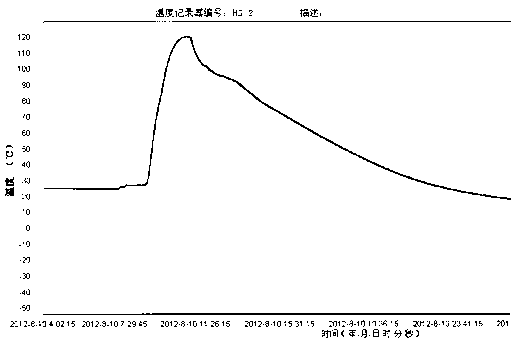

[0022] In summer (June 1-September 1), start the autoclave and vacuumize twice in a row. When the pressure in the autoclave reaches -0.055Mpa for the first time, stop, and when the pressure returns to 0.010Mpa, start the second Vacuum for the first time to make the pressure reach -0.055Mpa; stop for sterilization at 100°C for 30 minutes, then raise the temperature to 122°C and stop for 60 minutes for sterilization; drainage: start from the end of the second vacuuming and the pressure returns to positive pressure, Until the end of the sterilization process; suffocation: close the drain valve and suffocate for 20 minutes; exhaust to reduce the pressure in the sterilizer to 0; the cooling chamber exits the autoclave. See image 3 .

Embodiment 2

[0023] Example 2: In winter (November 1-March 1), preheat to 30°C, let the cold air in the autoclave be exhausted, so as not to form too much condensed water due to the overcooling in the autoclave; Start the sterilizer; vacuumize twice in a row, stop when the pressure reaches -0.055Mpa for the first time, and when the pressure returns to 0.010Mpa, start vacuuming for the second time to make the pressure reach -0.055Mpa; directly raise the temperature to 122 Sterilize at ℃ for 90 minutes; drainage: from the end of the second vacuum pumping, the pressure returns to positive pressure, to the end of the sterilization process; suffocation: close the drain valve and suffocate for 20 minutes; exhaust to reduce the pressure in the sterilizer Reduced to 0; cooling chamber out of the kettle.

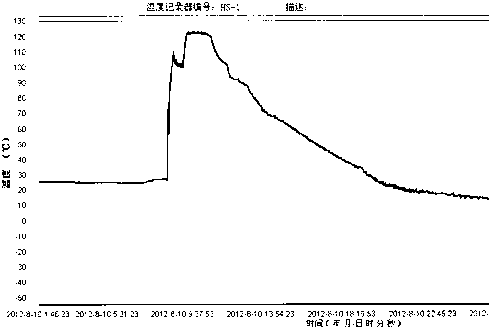

[0024] Such as Figure 4 The shown bottled Flammulina velutipes industrial production sterilization process curve, stay at 100°C for 30 minutes, then raise the temperature to 122°C and stay for...

Embodiment 3

[0025] Example 3: In spring and autumn (March 1-June 1; September 1-November 1), preheat to 30°C, let the cold air in the autoclave be exhausted, so as not to cause damage to the autoclave Excessive condensed water is formed due to internal supercooling; start the autoclave; vacuumize twice in a row, stop when the pressure reaches -0.055Mpa for the first time, and start the second vacuumize when the pressure returns to 0.010Mpa, Make the pressure reach -0.055Mpa; heat up, stay at 100°C for 30 minutes for sterilization, then raise the temperature to 122°C and stay for 60 minutes; Drainage: from the end of the second vacuuming, the pressure returns to positive pressure, and the end of the sterilization process; Suffocation: close the drain valve, and suffocate for 20 minutes; exhaust to reduce the pressure in the autoclave to 0; exit the autoclave from the cooling chamber. See Figure 5 .

[0026] The following is the output table of bottled Flammulina velutipes industria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com