Form grinding wheel dresser

A grinding wheel dresser and forming grinding technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, and abrasive surface adjustment devices, etc., can solve the problems of easy wear and tear of electroforming rollers, difficult to manufacture rollers, and long preparation cycle. , to achieve the effect of shortened manufacturing cycle, simple manufacturing process and rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings.

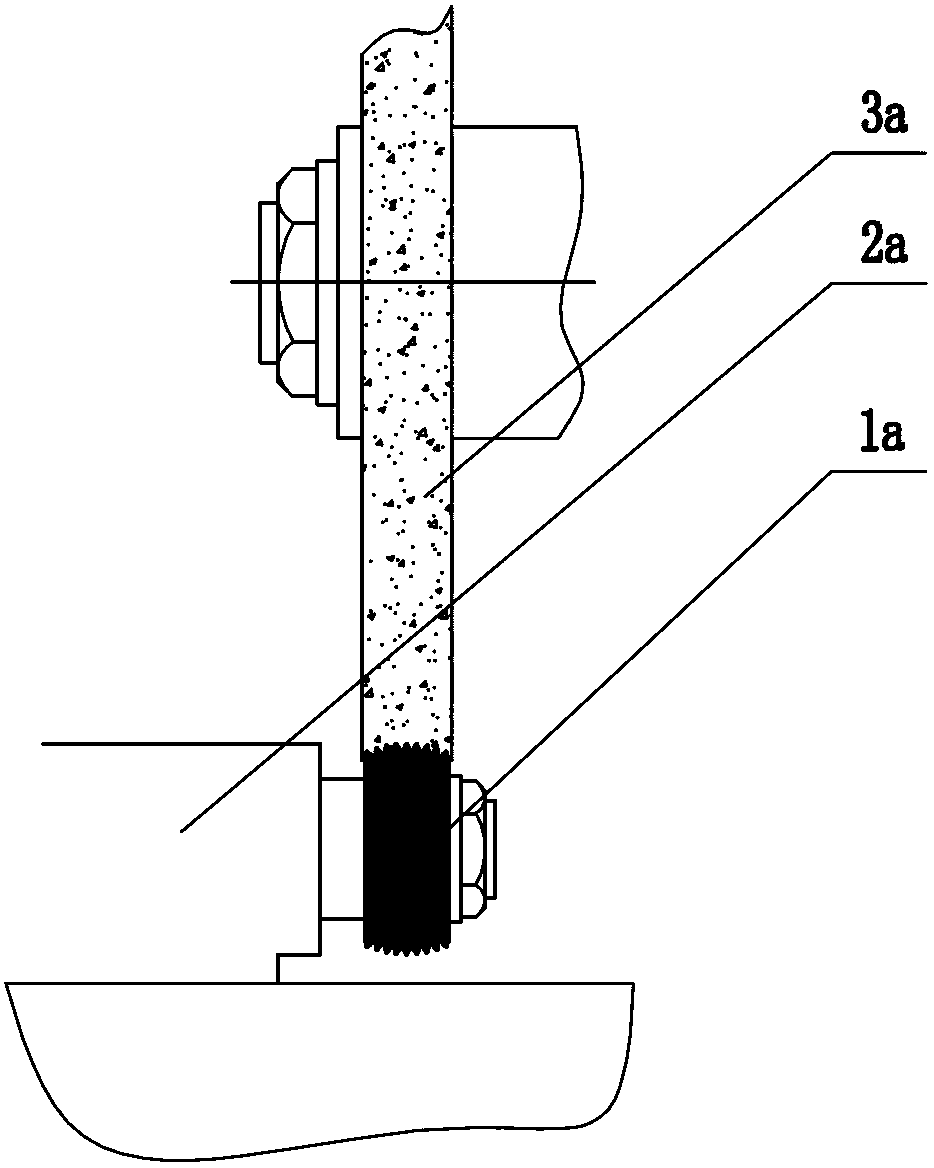

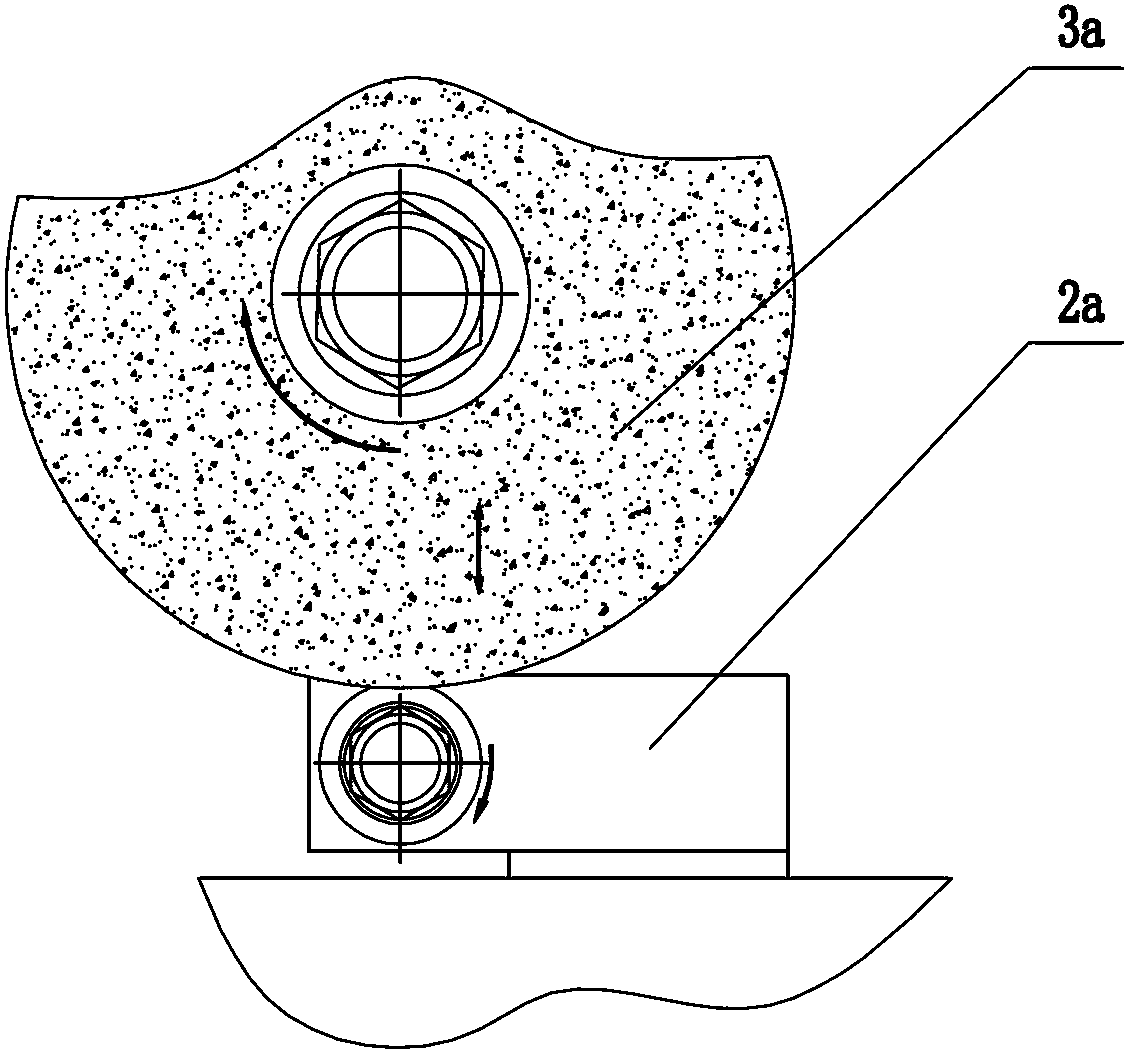

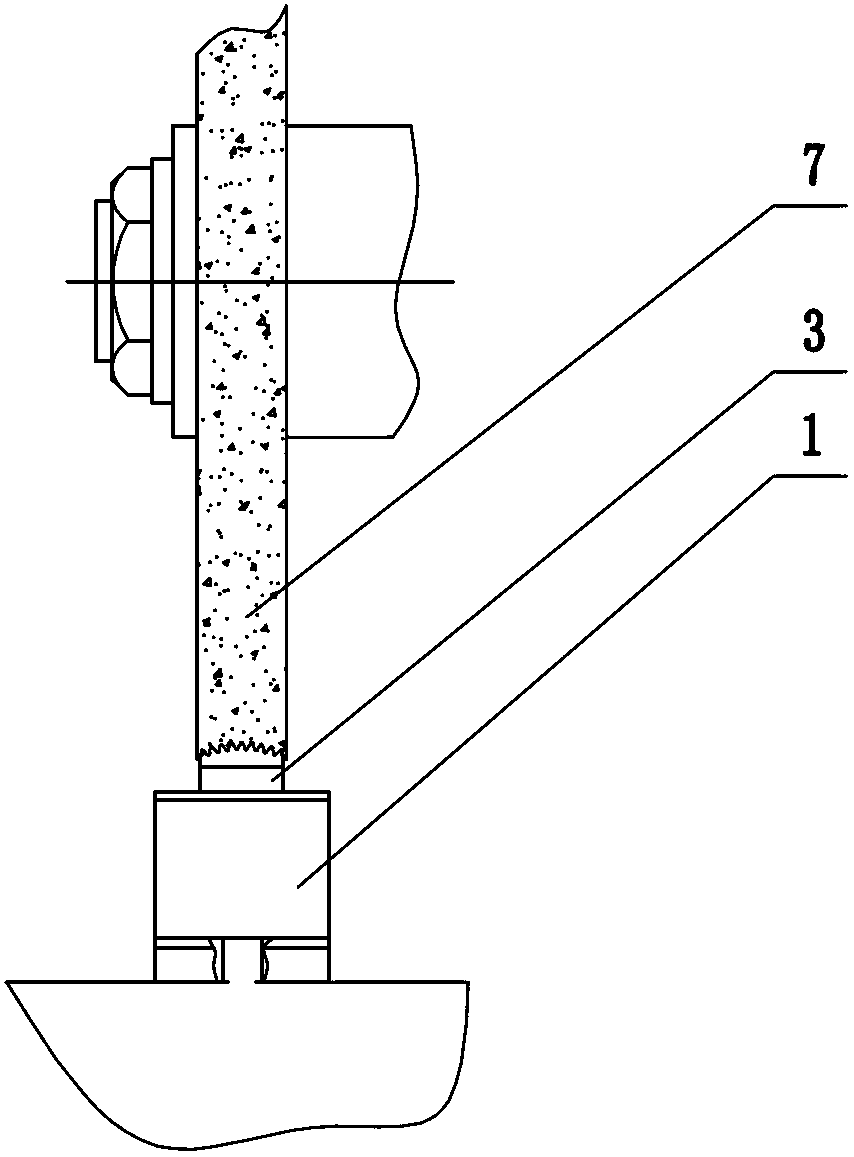

[0016] Such as Figure 2~Figure 7 As shown: the shaped grinding wheel dresser includes a dresser fixing seat 1, a clamping groove 2, a grinding wheel dresser 3, a dresser pressing pad 4, a hard alloy substrate 5, an artificial diamond grinding head 6, and the like.

[0017] Such as figure 2 , image 3 As shown, the present invention includes a dresser fixing seat 1 installed on the grinding machine workbench, the upper end of the dresser fixing seat 1 is provided with a clamping groove 2, and a grinding wheel dresser 3 is arranged in the clamping groove 2, and the grinding wheel dresser 3 is fixed by the dresser The bolts on the side of the seat 1 push the trimmer to press the pad 4 to be pressed between the inner walls of the clamping groove 2; Figure 4~Figure 7 As shown, the grinding wheel dresser 3 includes a columnar cemented carbide substrate 5, the upper surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com