Integrated control system for continuous conveying and precise metering of powdery material

A technology for comprehensive control and powdery materials, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., to achieve the effects of improving measurement accuracy, reducing labor intensity, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

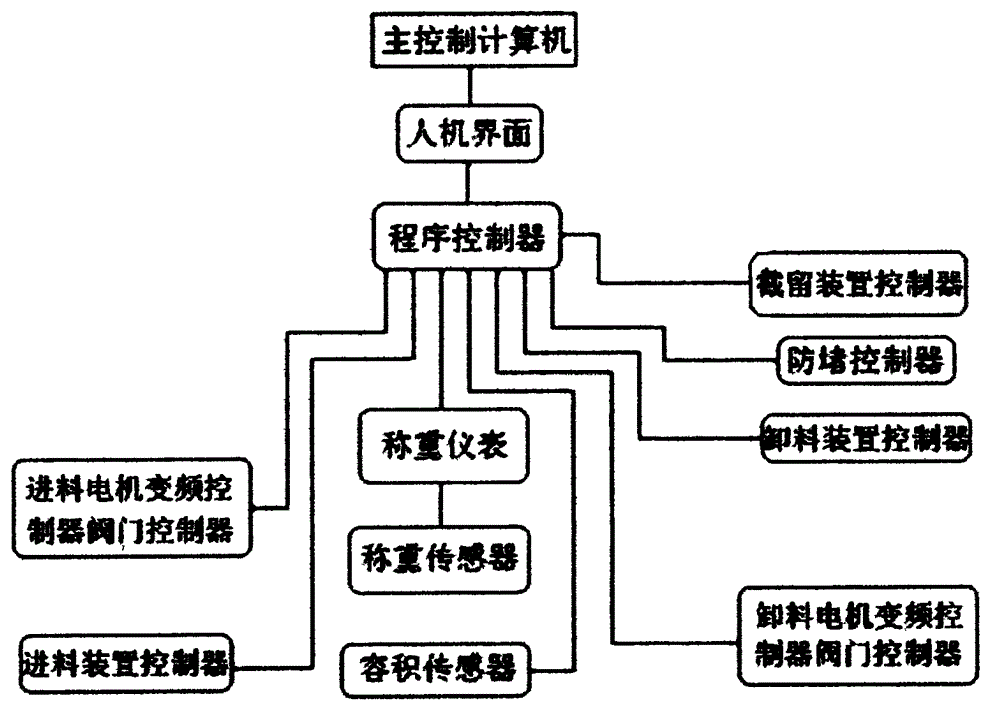

[0009] The integrated control system for continuous conveying and accurate metering of powdered materials in this embodiment is shown in the figure. The program controller is connected to the main control computer through the man-machine interface through the control line, and the program controller is connected to the feeder through the control line. Motor variable frequency controller, valve controller and feeding device controller control the conveying equipment at the feeding end; the program controller controls the metering end equipment through the volume sensor connected through the control line and the weighing sensor connected through the control line through the weighing instrument; program control The device is connected to the interception device controller, the anti-blocking controller, the unloading device controller, the unloading motor variable frequency controller, and the valve controller to control the discharge end conveying equipment through the control line....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com