Intelligent blast energy-saving control method for lime calcining kiln

A technology of energy-saving control and calcination kiln, which is applied in the field of lime kiln and can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

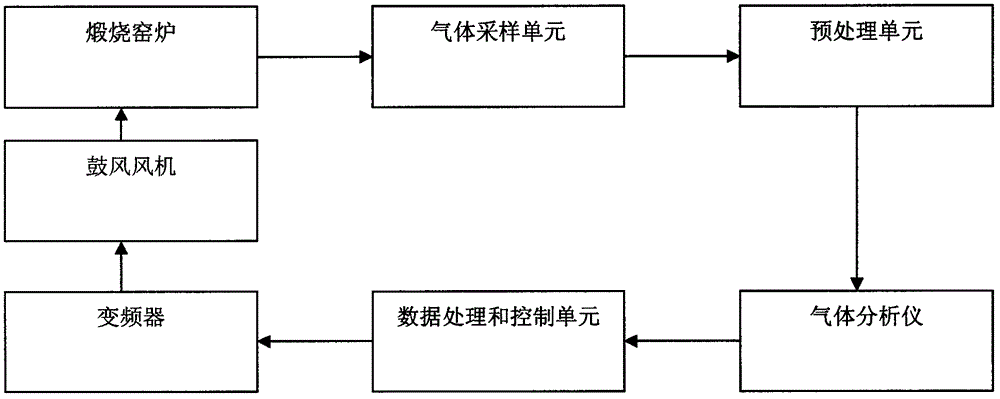

[0008] According to attached figure 1 , the method of the present invention uses a gas sampling unit, a preprocessing unit, a gas analyzer, a data processing and control unit, and a frequency converter for detection and control. The gas is sent from the gas sampling unit to the pretreatment unit through the dust filter to remove moisture, then dried and dedusted and sent to the gas analyzer. The gas analyzer uses an infrared gas analyzer to analyze the oxygen, carbon monoxide and carbon dioxide in the tail gas in real time. The component content data is converted into an electrical signal; the data processing and control unit uses a PLC circuit or an industrial computer to process the electrical signal of the gas component; the frequency converter receives the signal from the data processing and control unit and executes the process of increasing or decreasing the frequency operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com