O type low-speed anaerobic reactor

An anaerobic reactor and low-speed technology, which is applied in the field of anaerobic reactors, can solve problems such as many fault points, difficult operation and management, and complex structure, and achieve the effects of convenient operation, easy automatic monitoring, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

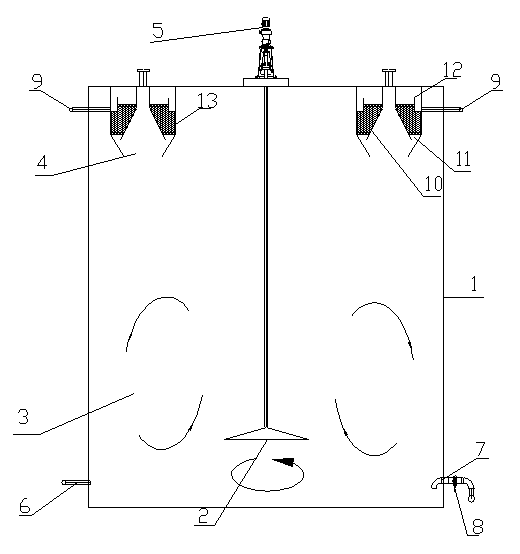

[0012] As shown in the accompanying drawings, the O-type anaerobic bioreactor of the present invention mainly includes a pool body 1 . The pool body 1 adopts a steel structure or a steel concrete structure, and the entire structure is a cylindrical structure with an O-shaped (circular) section. The tank body 1 is divided into two areas, the lower main reaction area 3 and the upper gas-solid-liquid separation area 4, the height ratio of which is 2:1-4:1. The pool body 1 is provided with a water inlet pipe 6 . The bottom of the tank body 1 is also provided with a mud discharge pipe 7, and a control valve 8 is arranged on the mud discharge pipe 7. The mud discharge pipe 7 is connected with an external pipeline to form a mud discharge system. Bottom sludge discharge. The main reaction zone 3 is provided with a stirring device 2, the stirring device 2 is composed of a stirring rod and a stirring fin, at least two sets of stirring fins are arranged on the stirring rod, and each gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com