Circulating water treatment device for industrial culture

A processing device and circulating water technology, which is applied in the field of indoor circulating aquaculture system, can solve the problems of aquatic organisms such as impracticality, low space utilization rate, and unsightly appearance, and achieve good disease control effect, good water treatment effect, The effect of low running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

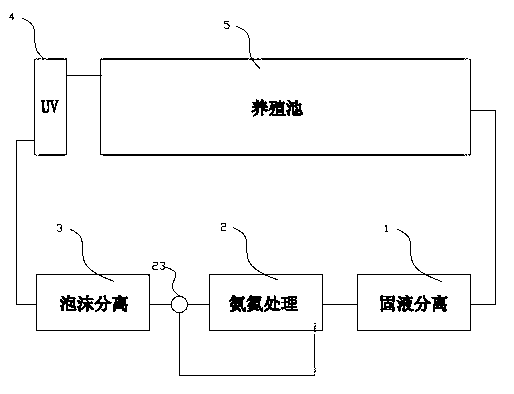

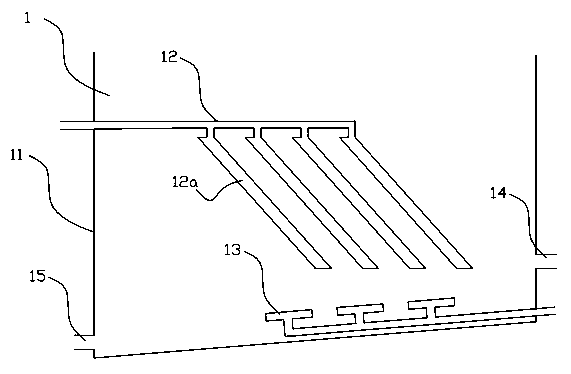

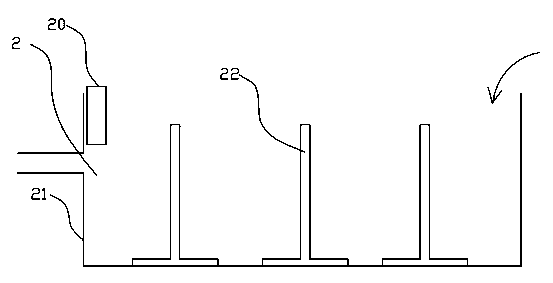

[0017] Example: refer to Figure 1 to Figure 6 , industrialized breeding circulating water treatment device, including a solid-liquid separation tank 1, an ammonia nitrogen treatment tank 2, a foam separation tank 3, an ultraviolet sterilizing device 4 and a culture tank 5 connected in sequence to form a circuit, wherein: the solid-liquid separation tank 1 The bottom of the separation tank body 11 is inclined to one side and is provided with a sewage pipe 15 near the bottom; the bottom of the solid-liquid separation tank body 11 is evenly distributed with aeration discs 13; The solid-liquid separation plate 12a arranged obliquely; the lower side of the solid-liquid separation plate 12a is evenly distributed with dense holes, and the solid-liquid separation plate 12a is also connected to the solid-liquid separation outlet pipe 12 . The aquaculture sewage enters the solid-liquid separation tank body 11 through the water inlet pipe 14, churns under the action of the gas of the ae...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com