Rubber composition for tire sidewall part of run-flat tire

A technology for run-flat tires and rubber compositions, used in tire parts, special tires, vehicle parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

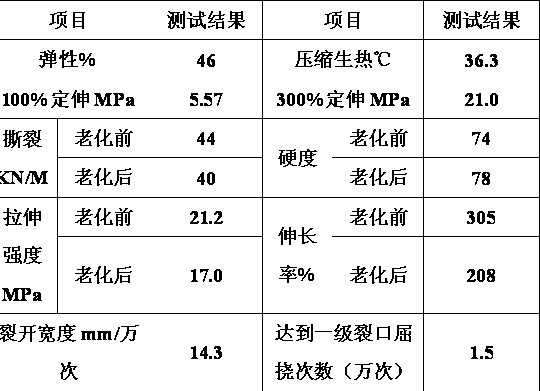

Embodiment 1

[0024] The formula is as follows:

[0025] Recipe Table 1

[0026] raw material natural rubber Low cis gum N375 carbon black Aromatic oil stearic acid Zinc oxide Dosage (serving) 45 55 70 8 2 3 raw material Antiaging agent protective wax sulfur Accelerator Dosage (serving) 3.1 1 2 1.5

[0027] Preparation Process:

[0028] Mixing: Two-stage mixing process, one-stage internal mixing process (1.5L Farrel internal mixer, 80°C / 80 rpm), and second-stage open mixing process

[0029] The initial temperature of the internal mixer was set at 80°C. Close the discharge port, fix the rotor, and raise the top bolt.

[0030] The first step is to add rubber, put down the top bolt, and masticate the rubber.

[0031] In the second step, after 1 minute, raise the top bolt, fill in 2 / 3 carbon black, zinc oxide, stearic acid, anti-aging agent, protective wax, etc., pu...

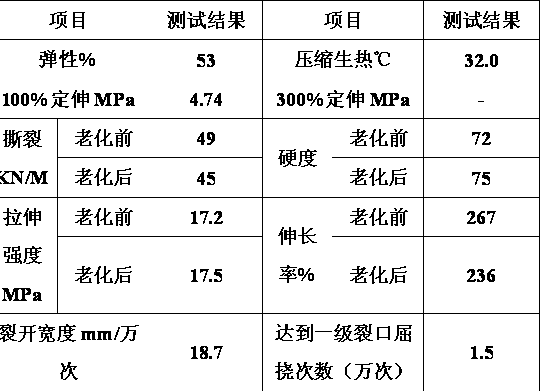

Embodiment 2

[0043] The formula is as follows:

[0044] Recipe Table 2

[0045] raw material natural rubber Low cis gum N375 carbon black Silica Silicon 69 Aromatic oil Dosage (serving) 45 55 33 35 2.8 8 raw material stearic acid Zinc oxide Antiaging agent protective wax sulfur Accelerator Dosage (serving) 2 3 3.1 1 2 1.5

[0046] Preparation Process:

[0047] Mixing: Two-stage mixing process, one-stage internal mixing process (1.5L Farrel internal mixer, 80°C / 80 rpm), and second-stage open mixing process

[0048] The initial temperature of the internal mixer was set at 80°C. Close the discharge port, fix the rotor, and raise the top bolt.

[0049] The first step is to add rubber, put down the top bolt, and masticate the rubber.

[0050] In the second step, after 1 minute, raise the top bolt, fill in white carbon black, zinc oxide, stearic acid, anti-aging agent, pro...

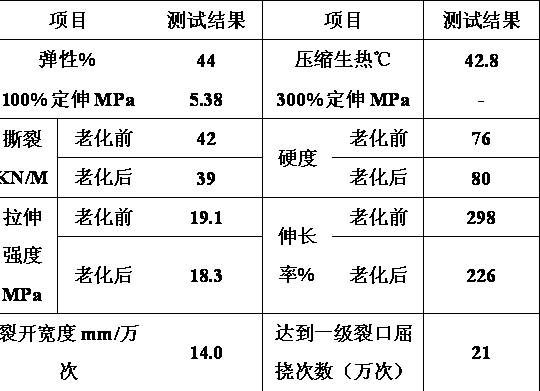

Embodiment 3

[0060] The formula is as follows:

[0061] Recipe Table 3

[0062] raw material natural rubber Low cis gum N375 carbon black Silica Silicon 69 Aromatic oil Dosage (serving) 45 55 33 35 2.8 8 raw material stearic acid Zinc oxide Antiaging agent protective wax sulfur Accelerator Dosage (serving) 2 3 3.1 1 2 2.0

[0063] Preparation Process:

[0064] With embodiment 2.

[0065] Performance table of sidewall rubber 3

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com