Pigment composition with anti-warping property in plastics

A pigment composition and anti-warping technology, applied in the field of pigment compositions, can solve the problem of low anti-warping performance, and achieve the effect of improving anti-warping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

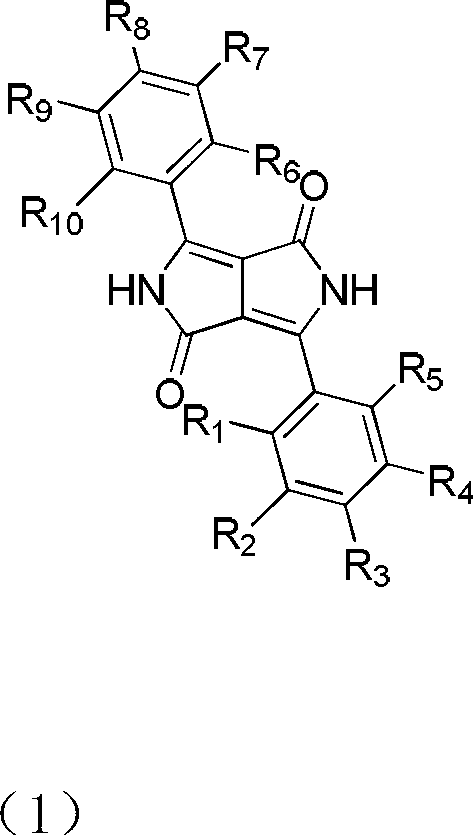

Image

Examples

Embodiment 1

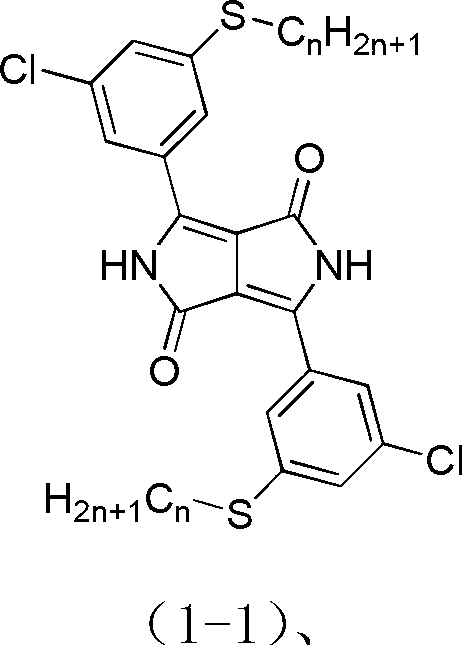

[0031] Dry-mix 9.5g of Pigment Red 254 with 0.5g of the additive of the following structural formula (1-1), and use the mixture to color polyethylene boards to test the warpage of the polyethylene boards.

[0032]

[0033] (1-1)

[0034] The additive of formula (1-1) can be prepared by the method of US7417154.

[0035] Test method: Mix 600g of polyethylene pellets and 0.6g of the above pigment mixture evenly, disperse in a single-screw extruder at 200°C and granulate, then inject the masterbatch into a disc with a diameter of 15cm and a thickness of 2.5cm in an injection molding machine , the disc was kept warm in hot water at 90°C for 30 minutes, and placed at room temperature for 24 hours. The test was repeated 10 times, and the warpage height of 10 injection molded parts was measured and averaged.

[0036] The test results are as follows:

[0037] Example

[0038] The results show that polyethylene panels colored with the composition of the invention have sig...

Embodiment 2

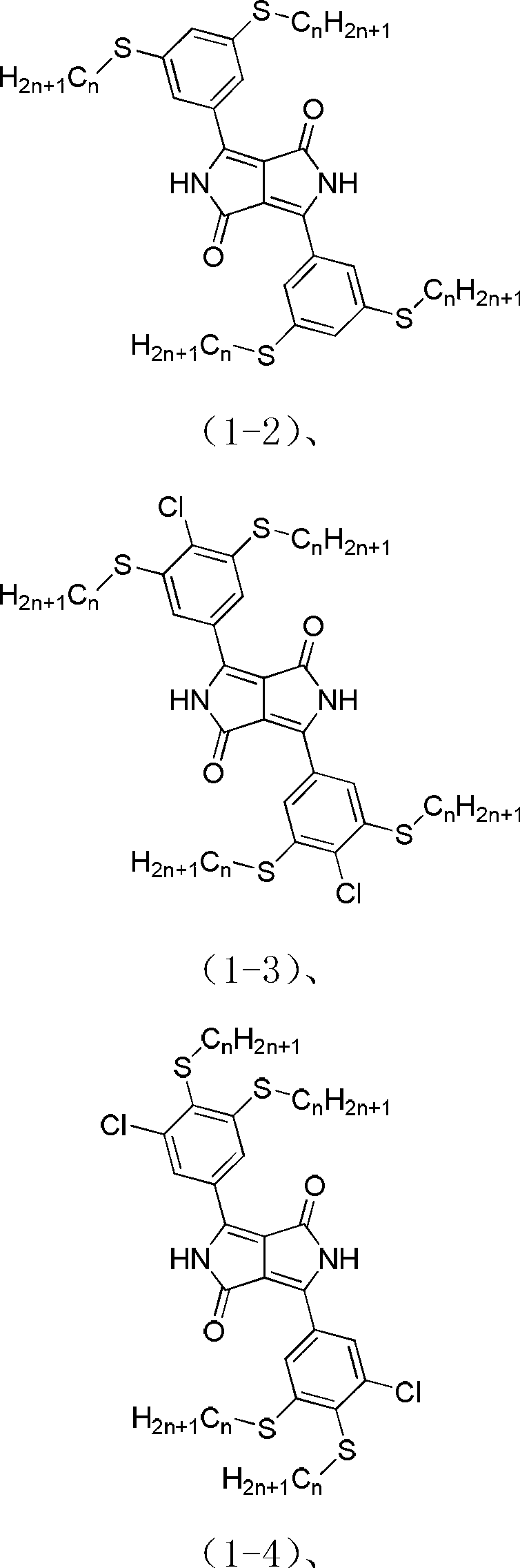

[0040] Dry-mix 9.7g of Pigment Red 254 and 0.3g of the additives with the following structure evenly, and then use the mixture to color polyethylene boards, and test the warpage of polyethylene boards.

[0041]

[0042] The additive of formula (1-2) can be prepared by the method of US7417154.

[0043] Test method is with embodiment 1, and result is as follows:

[0044] Example

[0045] The results show that polyethylene panels colored with the composition of the invention have significantly lower warpage than polyethylene panels colored with pure Pigment Red 254.

Embodiment 3

[0047] Dry-mix 9g of Pigment Yellow 110 and 1g of the additive with the following structure, and then use the mixture to color polyethylene boards, and test the warpage of polyethylene boards.

[0048]

[0049] The additive of formula (1-3) can be prepared by the method of US7417154.

[0050] Test method is with embodiment 1, and result is as follows:

[0051] Example

[0052] The results show that polyethylene sheets colored with the composition of the invention have significantly lower warpage than polyethylene sheets colored with pure Pigment Yellow 110.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com