Surface skid-resistant coating composition

A technology of anti-slip coatings and compositions, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of unfavorable anti-slip properties of coatings, harmful to human health, and unfavorable anti-slip properties of coatings, and achieve easy delamination and anti-slip Good performance and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

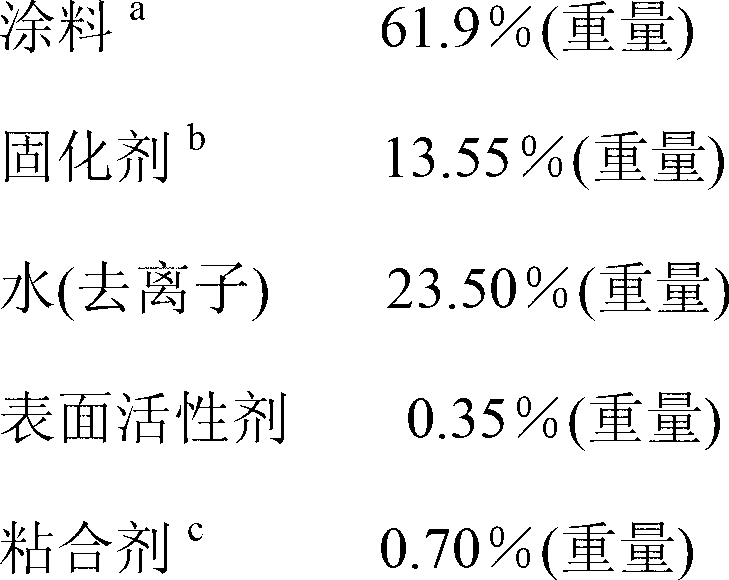

[0050] A surface anti-skid coating composition, said composition comprises by weight parts:

[0051] (A) 75 parts by weight of bisphenol A epoxy resin and silicone resin; the weight ratio of the epoxy resin and silicone resin is 5;

[0052] (B) 30 parts by weight of polypropylene particulate material having an average size of 200 microns; and

[0053] (C) 13 parts by weight of an amine functional curing agent.

Embodiment 2

[0055] A surface anti-skid coating composition, said composition comprises by weight parts:

[0056] (A) 12 parts by weight of bisphenol F type epoxy resin and silicone resin; the weight ratio of the epoxy resin and silicone resin is 1;

[0057] (B) 60 parts by weight of EPDM rubber particulate material having an average size of 36 microns; and

[0058] (C) 2 parts by weight of an amine functional curing agent.

Embodiment 3

[0060] A surface anti-skid coating composition, said composition comprises by weight parts:

[0061] (A) 23 parts by weight of aliphatic epoxy resin and silicone resin; the weight ratio of the epoxy resin and silicone resin is 2;

[0062] (B) 55 parts by weight polypropylene particulate material having an average size of 360 microns; and

[0063] (C) 5 parts by weight of an amine functional curing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com