Green phosphor activated by cerium ions

A technology of green phosphors and cerium ions, applied in the field of green phosphors, can solve the problems of high color temperature, weak intensity, and low color rendering index of white LEDs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14

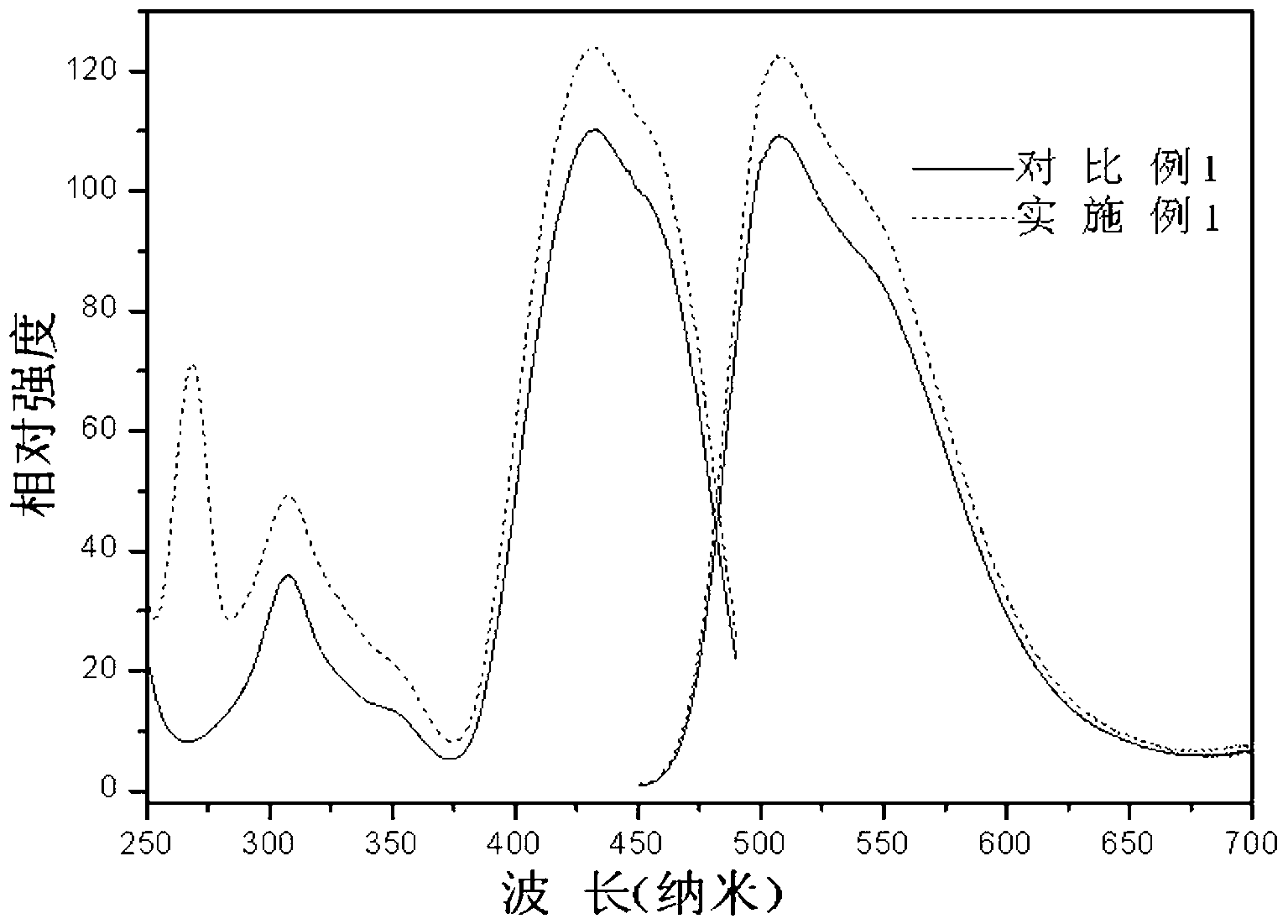

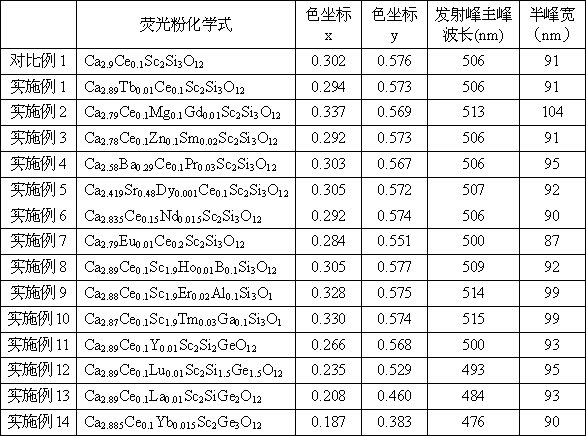

[0015] Embodiments 1 to 14: See Table 1 for the chemical formula. The preparation method is the same as in Comparative Example 1.

[0016] Table 1 Chemical formula and its color coordinates, emission main peak wavelength and half-peak width of Examples 1-14

[0017]

Embodiment 15~29

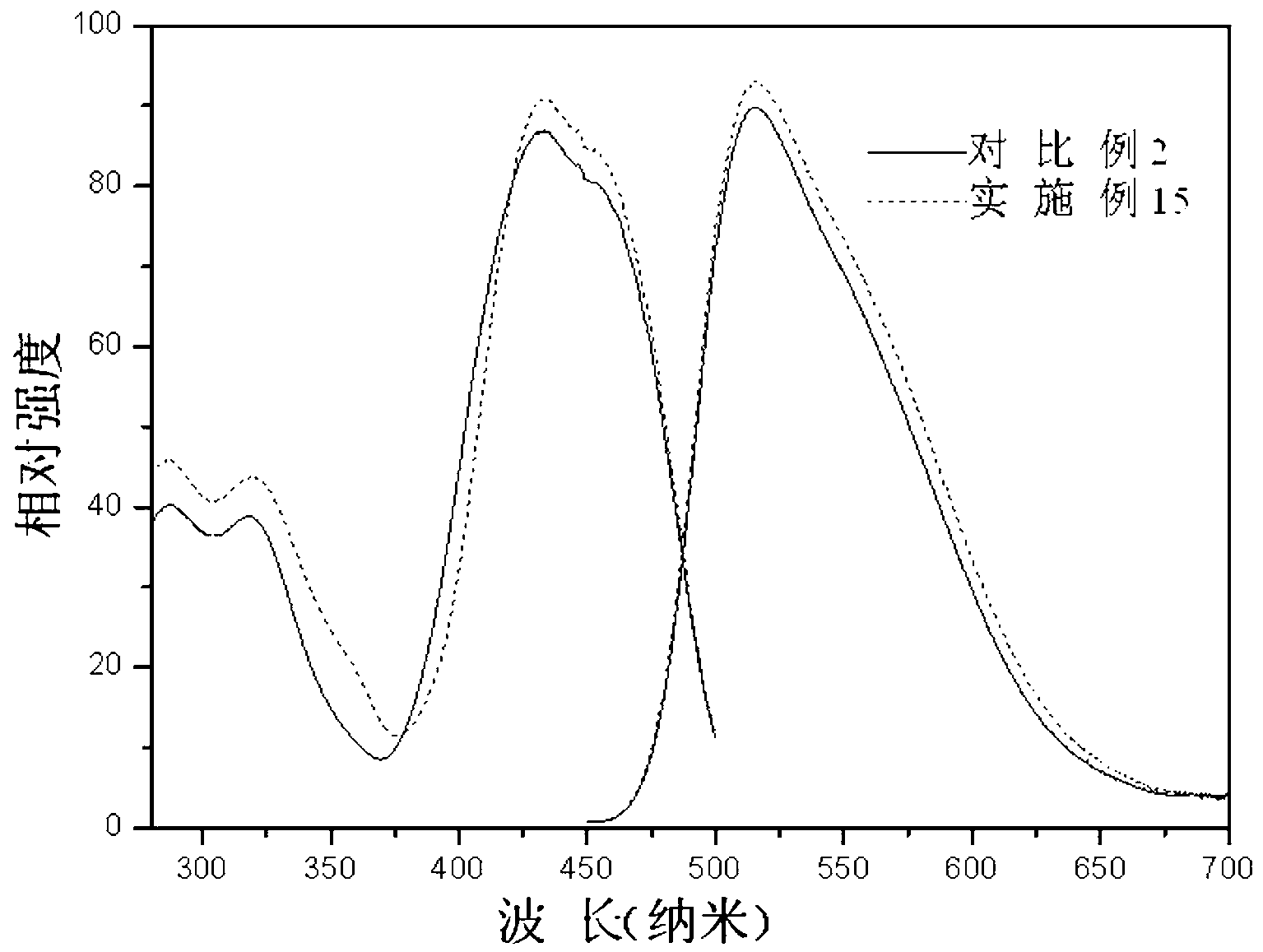

[0019] The chemical formula is shown in Table 2. The preparation method is the same as in Comparative Example 2.

[0020] Table 2 The chemical formula and its color coordinates, emission main peak wavelength and half-peak width of Examples 15-29

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com