Near-infrared light-emitting material, preparation method and light-emitting device

A technology of luminescent materials and light-emitting devices, which is applied in the direction of luminescent materials, chemical instruments and methods, semiconductor devices, etc., can solve problems such as narrow near-infrared emission bands, and achieve easy industrial operation, simple synthesis process, and no environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

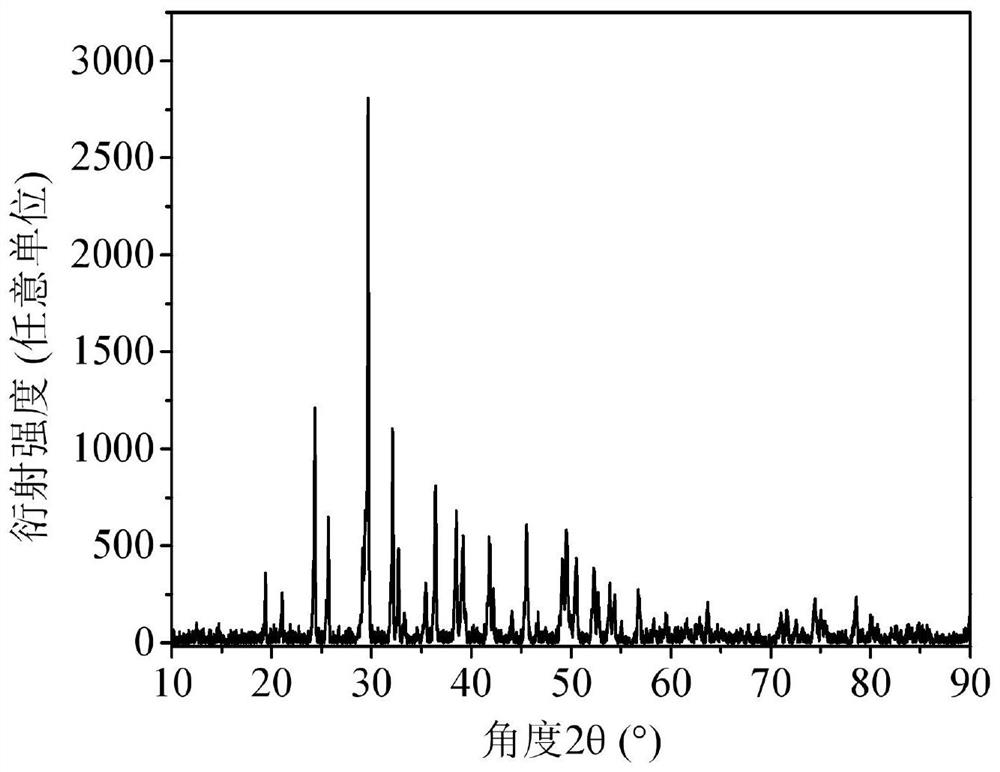

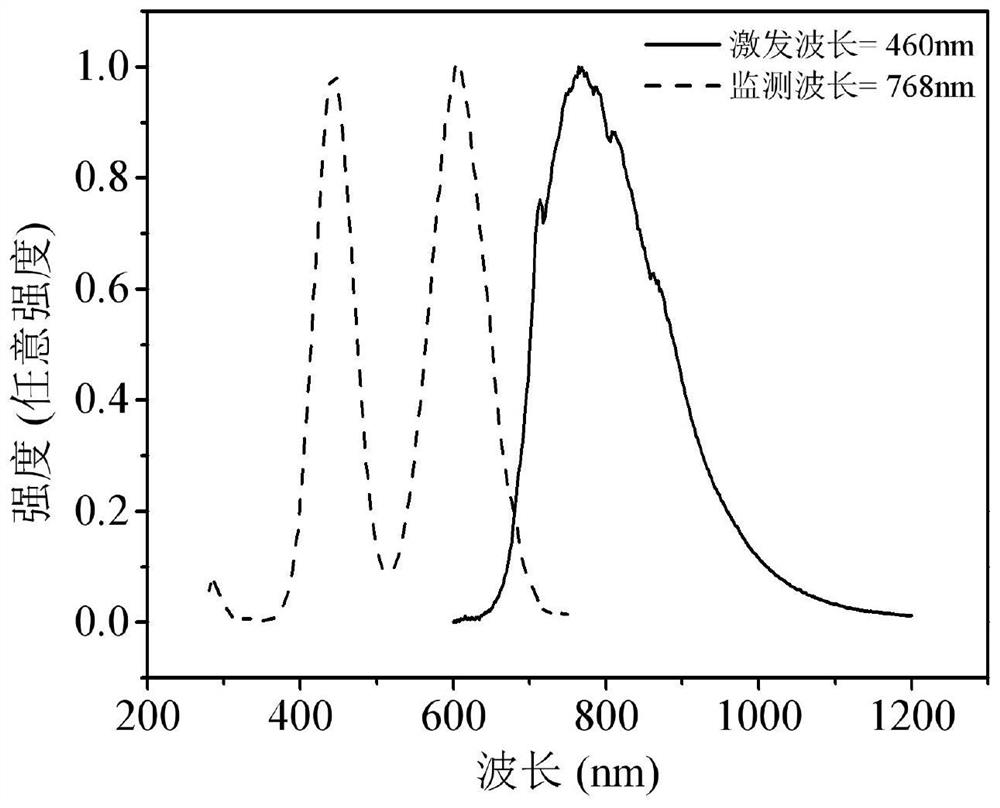

Embodiment 1

[0029] A near-infrared luminescent material whose theoretical chemical composition is Ca 3 sc 0.07 (BO 3 ) 3 : 0.03Cr, according to its stoichiometric ratio, accurately weigh CaCO 3 (analytical pure), Sc 2 o 3 (analytical pure), H 3 BO 3 (analytical pure), Cr 2 o 3 (Analytical pure) raw materials; after grinding and mixing the above raw materials evenly, sintering at 1100°C for 10h under air atmosphere, the heating rate is 4°C / min, and the sintered product is obtained after cooling to room temperature; the obtained sintered product is crushed, washed, and sieved , to obtain the final sample after drying. Utilize X-ray powder diffractometer to analyze the luminescent material obtained in embodiment 1, obtain the X-ray powder diffraction pattern of sample, as figure 1 shown. Utilize the fluorescence spectrometer to analyze the luminescent material in embodiment 1, obtain the excitation and emission spectrum of the sample, such as figure 2 shown. Depend on figure ...

Embodiment 2

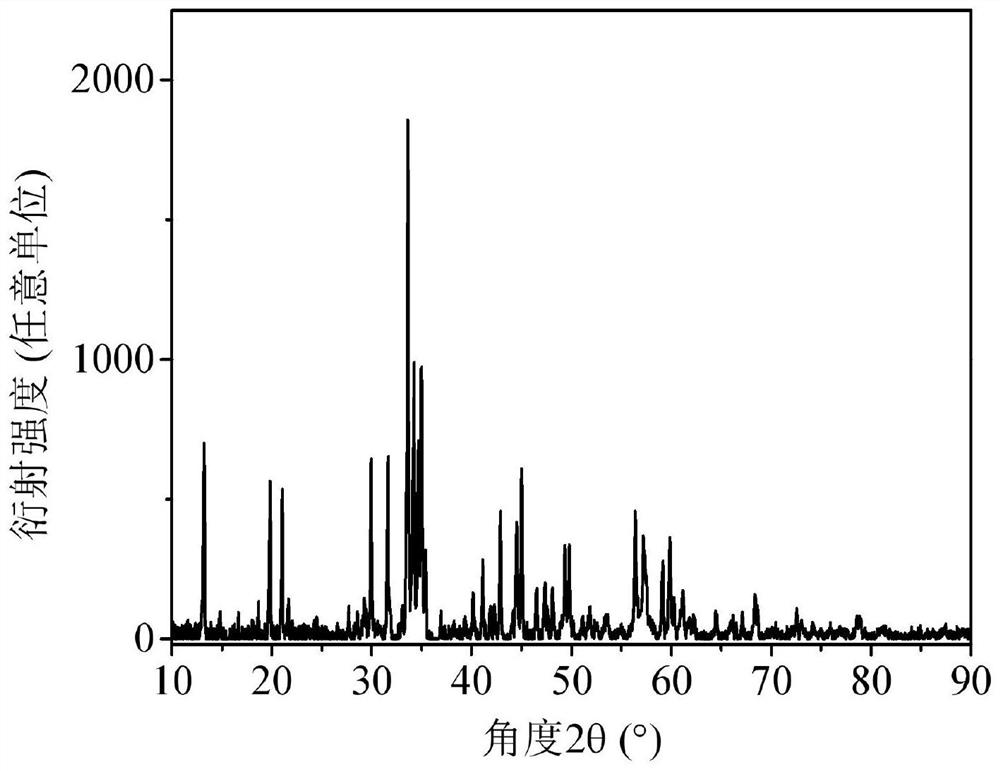

[0031] A near-infrared luminescent material whose theoretical chemical composition is Be 3 sc 0.07 (BO 3 ) 3 : 0.03Cr, according to its stoichiometric ratio, accurately weigh BeO (analytical pure), Sc 2 o 3 (analytical pure), H 3 BO 3 (analytical pure), Cr 2 o 3 (Analytical pure) raw materials; after grinding and mixing the above raw materials evenly, sintering at 1200°C for 10h under air atmosphere, the heating rate is 4°C / min, and the sintered product is obtained after cooling to room temperature; the obtained sintered product is crushed, washed, and sieved , to obtain the final sample after drying. Utilize X-ray powder diffractometer to analyze the luminescent material obtained in embodiment 2, obtain the X-ray powder diffraction pattern of sample, as image 3 shown. Utilize the fluorescence spectrometer to analyze the luminescent material in embodiment 2, obtain the excitation and emission spectrum of the sample, such as Figure 4 shown. Depend on Figure 4 It...

Embodiment 3

[0033] A near-infrared luminescent material whose theoretical chemical composition is Ca 3 sc 0.07 (BO 3 ) 3 : 0.03Cr, according to its stoichiometric ratio, accurately weigh CaCO 3 (analytical pure), Sc 2 o 3 (analytical pure), H 3 BO 3 (analytical pure), Cr 2 o 3 (Analytical pure) raw materials; after grinding and mixing the above raw materials evenly, sintering at 1100°C for 10h under air atmosphere, the heating rate is 4°C / min, and the sintered product is obtained after cooling to room temperature; the obtained sintered product is crushed, washed, and sieved , to obtain the final sample after drying. Utilize the fluorescence spectrometer to analyze the luminescent material in embodiment 3, obtain the excitation and emission spectrum of the sample, such as Figure 5 shown. Depend on Figure 5 It can be seen that the luminescent material can be excited by blue light, and the main peak of the emission spectrum is located around 813nm. The full width at half maxim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com