Dual-emission fluorescent powder for LED plant illumination, and preparation method and application thereof

A plant lighting and phosphor technology, applied in the fields of botanical equipment and methods, applications, luminescent materials, etc., can solve the problem of ignoring the effect of far-red light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The chemical composition of the double-emission fluorescent powder obtained in this embodiment is K 2 Ca 0.99 PO 4 F:0.01Eu 2+ ,3wt%H 3 BO 3 .

[0039] The raw material composition of double emission phosphor powder in the embodiment 1 of table 1

[0040] raw material CaCO 3

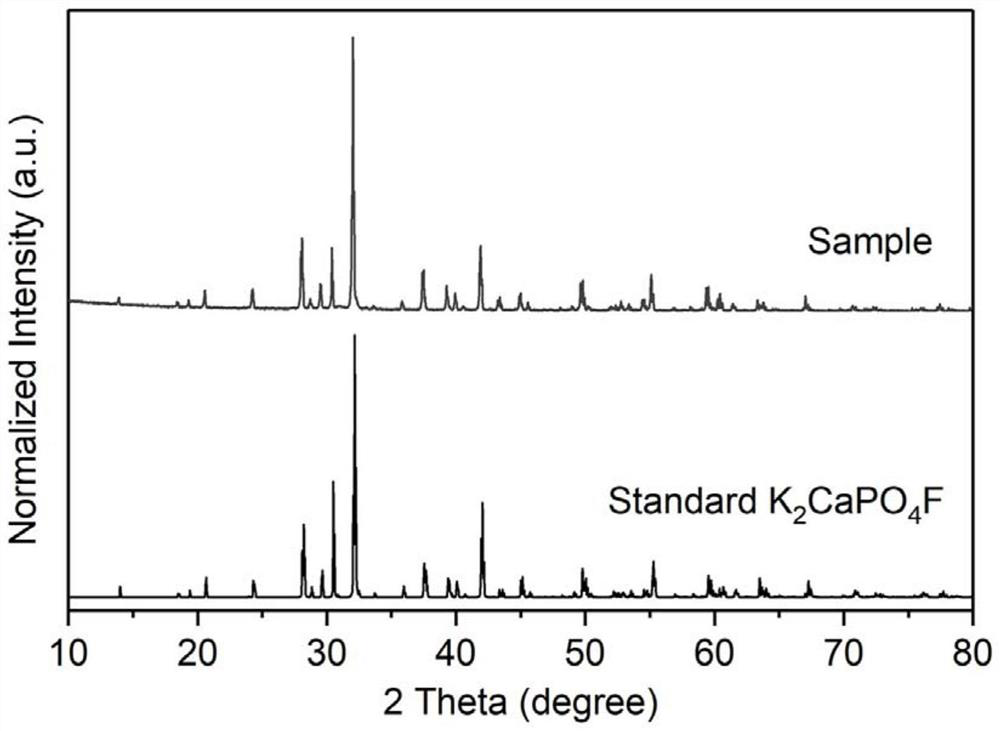

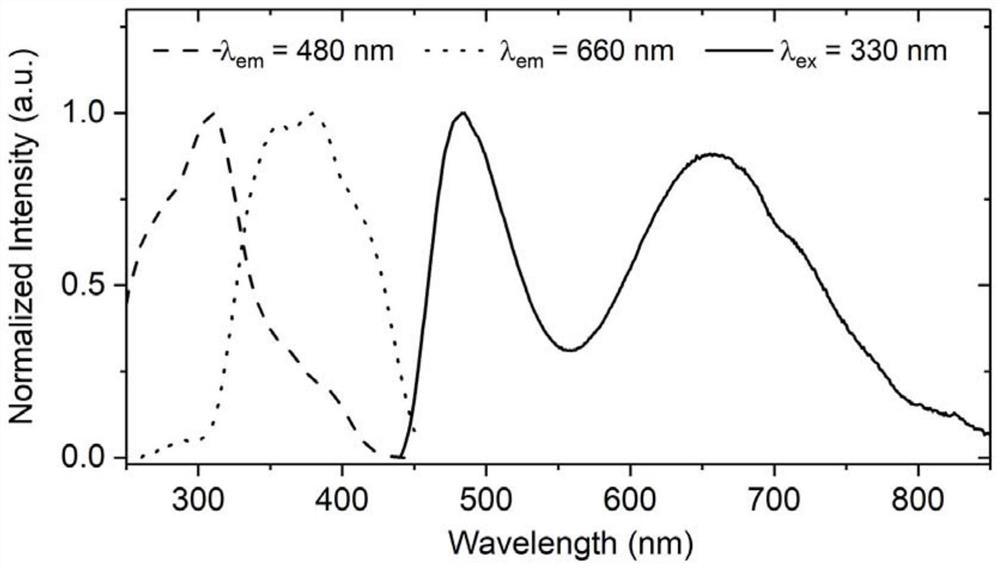

[0041] Accurately weigh analytically pure calcium carbonate (CaCO 3 ), calcium fluoride (CaF 2 ), Potassium dihydrogen phosphate (KH 2 PO 4 ), europium oxide (Eu 2 o 3 ), boric acid (H 3 BO 3 ). The accurately weighed raw materials were fully ground in an agate mortar, mixed evenly, placed in a corundum crucible, and then transferred to a tube furnace. 2 and N 2 Under a mixed reducing atmosphere, sinter in a tube furnace at 960°C for 6 hours, cool down to room temperature with the furnace, and grind to obtain a dual-emission phosphor sample. figure 1 Shown is the XRD collection of illustrative plates of the corresponding sample of embodiment 1, as can be seen, the X-r...

Embodiment 2

[0043] The chemical composition of the dual-emission fluorescent powder obtained in this embodiment is K 2 Ca (1-x) PO 4 F:xEu 2+ ,5wt%NH 4 F (x=0.002; 0.004; 0.008; 0.015; 0.020).

[0044] Different Eu in the embodiment 2 of table 2 2+ Raw material composition of doping concentration dual-emission phosphors

[0045]

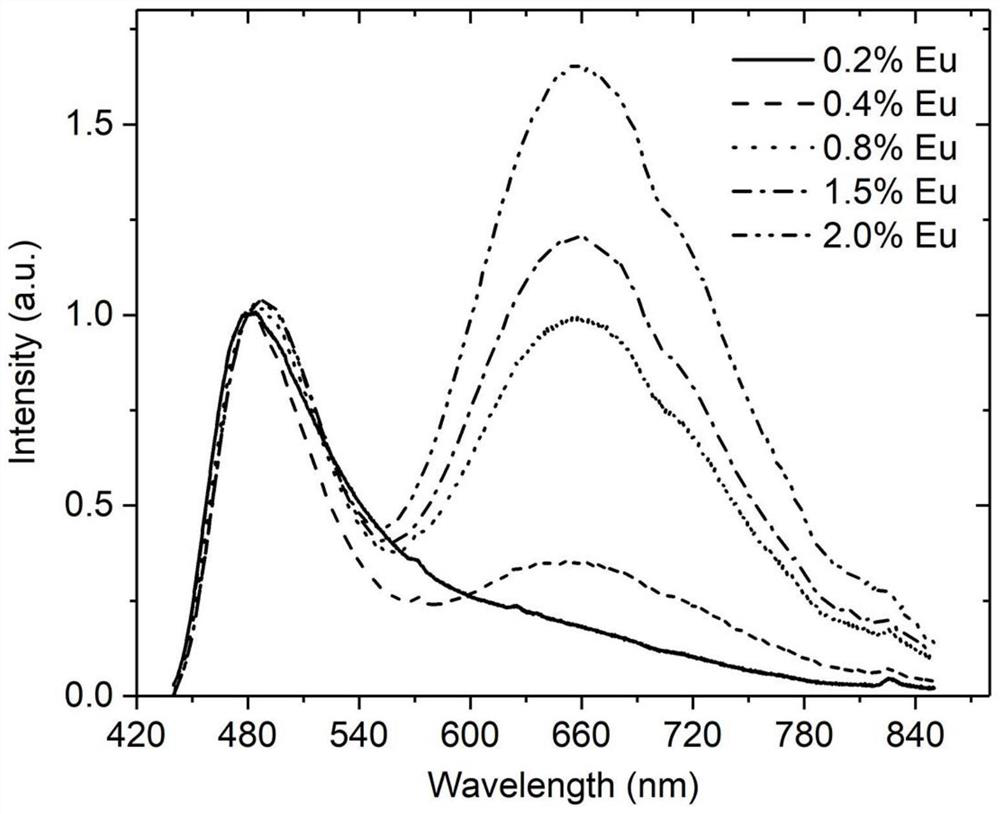

[0046] Accurately weigh analytically pure potassium carbonate (K 2 CO 3 ), potassium fluoride (KF), calcium carbonate (CaCO 3 ), ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ), europium oxide (Eu 2 o 3 ), ammonium fluoride (NH 4 F). The accurately weighed raw materials were fully ground in an agate mortar, mixed evenly, placed in a corundum crucible, and then transferred to a tube furnace. 2 and N 2 Under a mixed reducing atmosphere, sinter in a tube furnace at 1000°C for 8 hours, cool down to room temperature with the furnace, and grind to obtain a dual-emission phosphor sample. image 3 Shown are the emission spectra of samples with different...

Embodiment 3

[0048] The chemical composition of the double-emission fluorescent powder obtained in this embodiment is K 2 Ca 0.995 PO 4 F:0.005Eu 2+ ,8wt%LiF.

[0049] The raw material composition of double emission phosphor powder in the embodiment 3 of table 3

[0050] raw material CaCO 3

[0051] Accurately weigh analytically pure calcium carbonate (CaCO3) according to Table 3 3 ), calcium fluoride (CaF 2 ), Potassium dihydrogen phosphate (KH 2 PO 4 ), potassium carbonate (K 2 CO 3 ), europium fluoride (EuF 3 ), lithium fluoride (LiF). The accurately weighed raw materials were fully ground in an agate mortar, mixed evenly, placed in a corundum crucible, and then transferred to a tube furnace. 2 and N 2 Under a mixed reducing atmosphere, sinter in a tube furnace at 1050°C for 4 hours, cool down to room temperature with the furnace, and grind to obtain a dual-emission phosphor sample. It can be seen from the laser confocal imaging excited at 405nm that the dual-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com